Method for detecting PYF (premature yeast flocculation) factor in malt

A detection method, malt technology, applied in the direction of biochemical equipment and methods, microbial measurement/inspection, etc., can solve the problems of ineffective guidance, long inspection time, large error, etc., achieve accurate and fast detection results, and good filtration performance , to ensure the normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

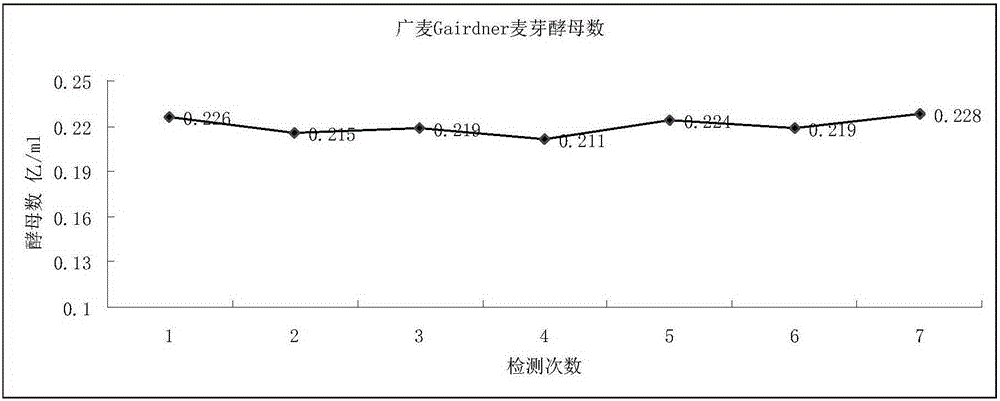

[0024] 1) Select COFCO Jiangyin Gairdner malt (COFCO Malt Jiangyin Co., Ltd.) with a yeast count ≥ 30 million / mL after 24 hours of experimental culture and fermentation as the standard malt, and prepare standard malt agreement wort according to the following method, which is recorded as agreement wort A;

[0025] 1.1) Weigh 50g of crushed malt powder (30-35 mesh, the same below) into a mash cup of known weight, add 200mL of secondary deionized water preheated to 45°C, and stir gently with a stirring rod , put the saccharification cup in the saccharification machine, keep stirring at 45°C for 30 minutes;

[0026] 1.2) Raise the temperature to 70°C at 1°C / min, add 100mL of secondary deionized water that has been preheated to 70°C into the mash cup, and keep it at 70°C for 60 minutes, then cool down to 20°C after the heat preservation is completed;

[0027] 1.3) Take out the mash cup from the cup hole, dry the outer wall, rinse the stirring bar with secondary deionized water, add...

Embodiment 2

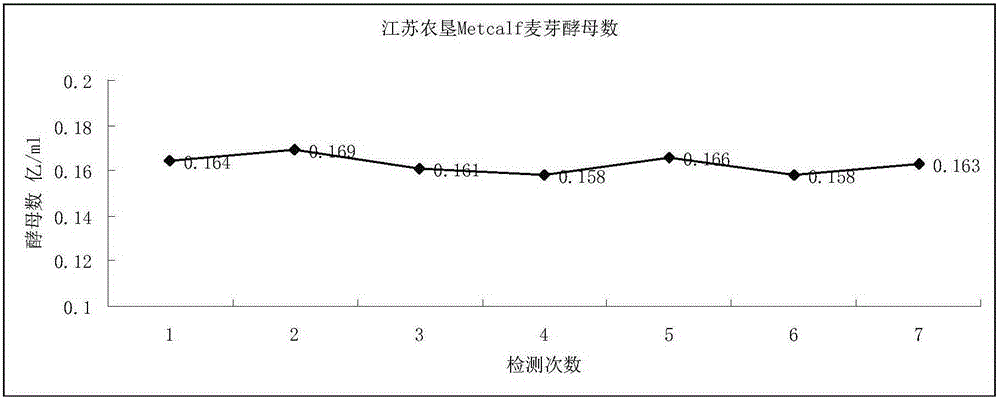

[0039] 1) Select COFCO Jiangyin Gairdner malt (COFCO Malt Jiangyin Co., Ltd.) with yeast count ≥ 0.3 billion / mL after 24 hours of experimental culture and fermentation as standard malt, and prepare standard malt agreement wort according to step 1.1) to step 1.4) of Example 1 , recorded as agreement wort A, standby; choose Jiangsu Nongken Metcalf malt (Jiangsu Nongken Malt Co., Ltd.) as the malt to be inspected, and prepare the agreement wort of the malt to be inspected according to step 1.1) to step 1.4) of Example 1, which is recorded as the agreement Wort B, spare;

[0040] 2) Aseptic operation Take the second-generation yeast mud that has been full for 6 days in production and put it in a beaker, add secondary deionized water, stir evenly and let it stand, remove the supernatant and bottom impurities, collect the suspension in the middle, Transfer to a centrifuge tube, add secondary deionized water to weigh and balance; then put the centrifuge tube into a refrigerated centr...

Embodiment 3

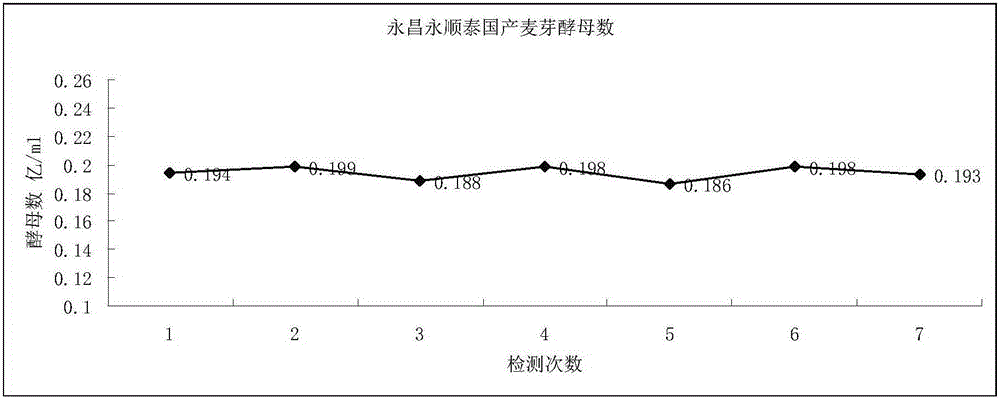

[0048] 1) Select COFCO Jiangyin Gairdner malt (COFCO Malt Jiangyin Co., Ltd.) with yeast count ≥ 0.3 billion / mL after 24 hours of experimental culture and fermentation as standard malt, and prepare standard malt agreement wort according to step 1.1) to step 1.4) of Example 1 , recorded as agreement wort A, standby; choose Yongchang Yongshun Thailand malt (Yongchang Yongshuntai Brewery Raw Materials Co., Ltd.) as the malt to be checked, and prepare the agreement malt of the malt to be checked according to step 1.1) to step 1.4) of Example 1 Juice, recorded as the agreement wort B, spare;

[0049] 2) Aseptic operation Take the 3rd generation yeast mud that has been in the production tank for 5 days and put it in a beaker, add secondary deionized water, stir evenly and let it stand, remove the supernatant and bottom impurities, collect the suspension in the middle, Transfer to a centrifuge tube, add secondary deionized water to weigh and balance; then put the centrifuge tube into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com