Gasoline engine with firm structure and good heat dissipation

A gasoline engine, engine block technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve problems such as poor stabilization effect, and achieve the effect of facilitating smooth circulation, increasing stability, and preventing distortion or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

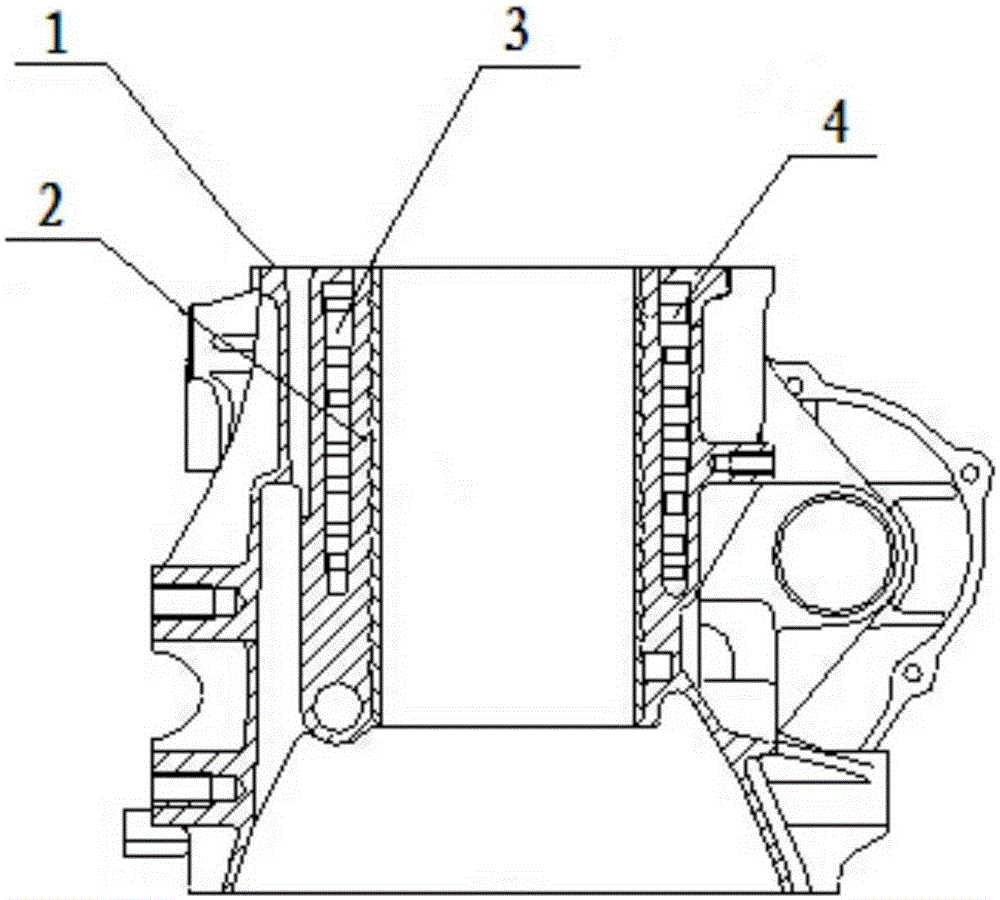

[0016] Example: such as figure 1 As shown, a gasoline engine with firm structure and good heat dissipation includes an engine block, a cylinder block 1 is installed in the engine block, a cylinder liner 2 is arranged in the cylinder block 1, and a cylinder liner around the cylinder liner 2 is arranged on the periphery of the cylinder liner 2. The water jacket 3 around 2 is provided with a reinforcing rib 4 of cast iron material between the cylinder liner 2 and the cylinder block 1, and the reinforcing rib 4 is cast integrally with the cylinder block 1 and the outer wall of the cylinder liner 2. The reinforcing ribs 4 are arranged according to the thread structure, and each round of the reinforcing ribs 4 of the thread structure is provided with a gap for antifreeze to pass through.

[0017] A reinforcing rib is arranged between the outer wall of the cylinder liner and the cylinder body, which increases the stability of the cylinder liner and effectively prevents the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com