Portable floating slurry pump

A mud pump, floating technology, applied in the direction of variable displacement pump components, pumps, pump components, etc., can solve problems such as hidden safety hazards and difficult operation by operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

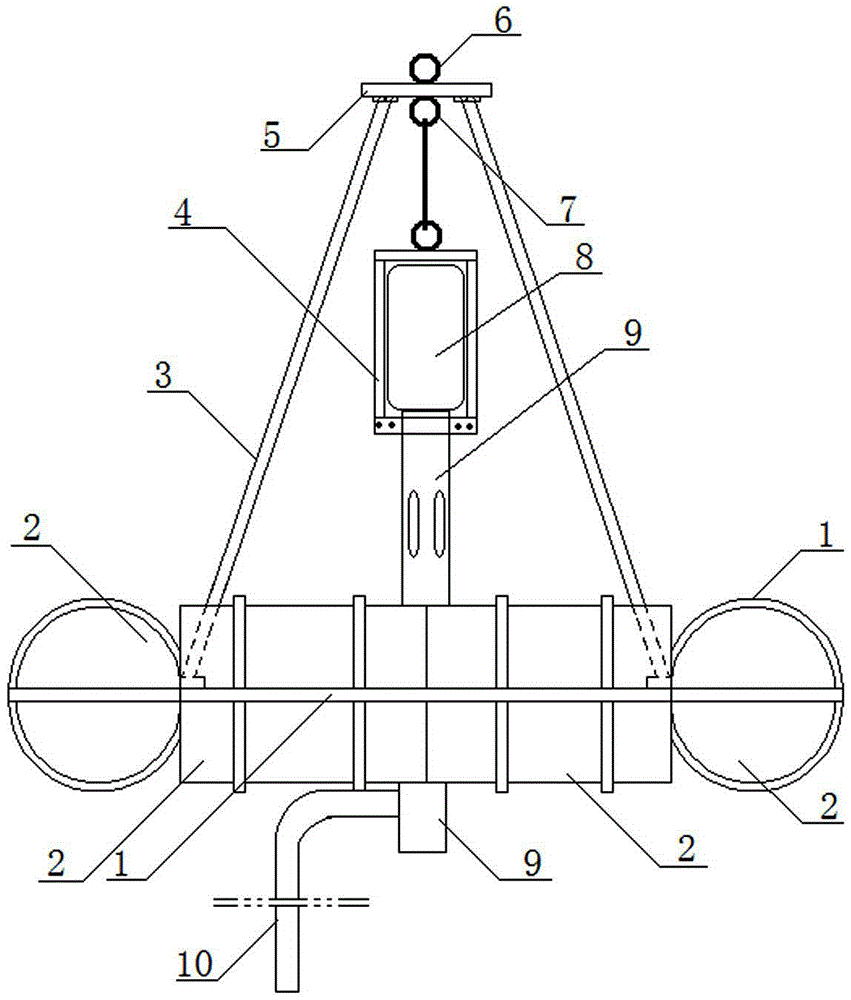

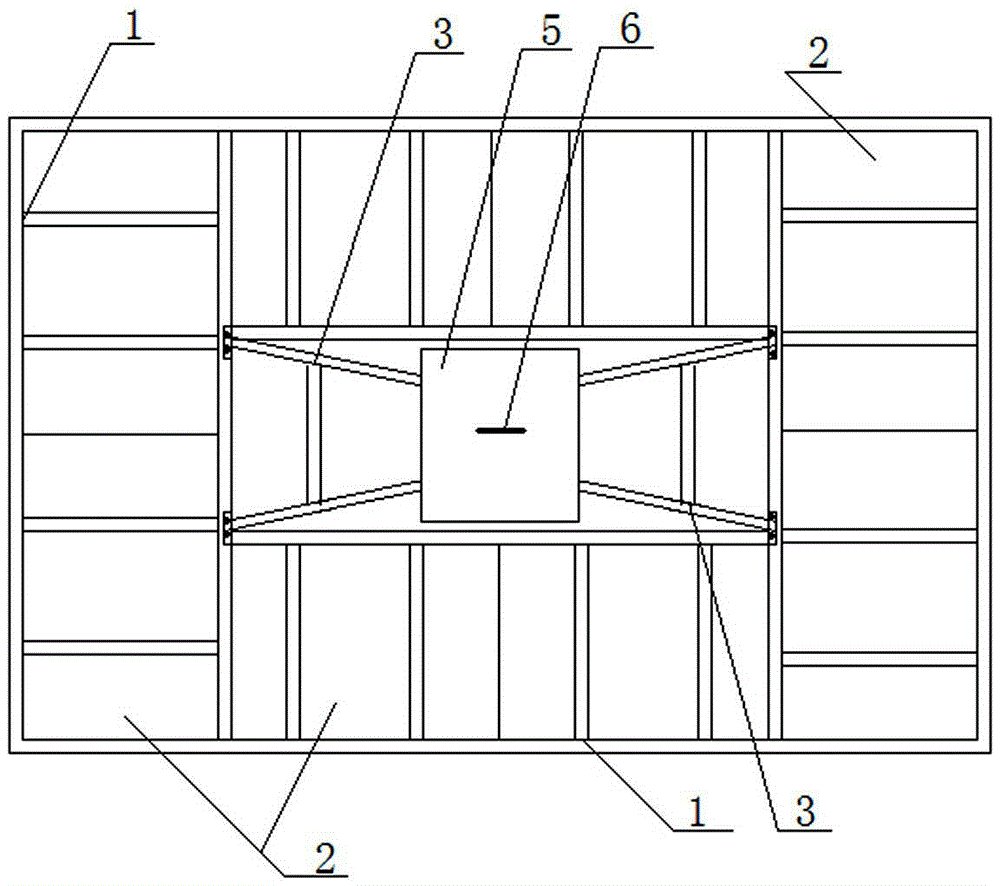

[0021] figure 1 Shown is a schematic diagram of the main structure of the present invention, combined with figure 1 top view of figure 2 Looking at it together, it can be seen that it includes a buoy frame 1, a buoy 2, a bracket 3, a suspension frame 4 and a top plate 5, wherein eight buoys 2 form a square and are fixed in a corresponding square frame-shaped buoy frame 1; 5 is provided with an upper suspension ring 6 for lifting and moving, and a lower suspension ring 7 for suspending the mud pump is provided below. Through the upper suspension ring 6, a crane or a hoist can be used to include the buoy frame 1, the buoy 2, the support 3 and the pump body. 9 overall lifting, moving to the transport vehicle or another piling place. The top surface of the support 3 is connected to the top plate 5 as a detachable fixed connection. Similarly, the connection between the bottom of the support 3 and the buoy frame 1 is also a detachable fixed connection, which is convenient for sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com