Vibration reduction ring for clutch driven disc

A vibration damping ring and clutch technology, applied in the field of clutches, can solve the problem of rapid wear of the damping ring, and achieve the effects of avoiding rapid wear, reducing contact area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

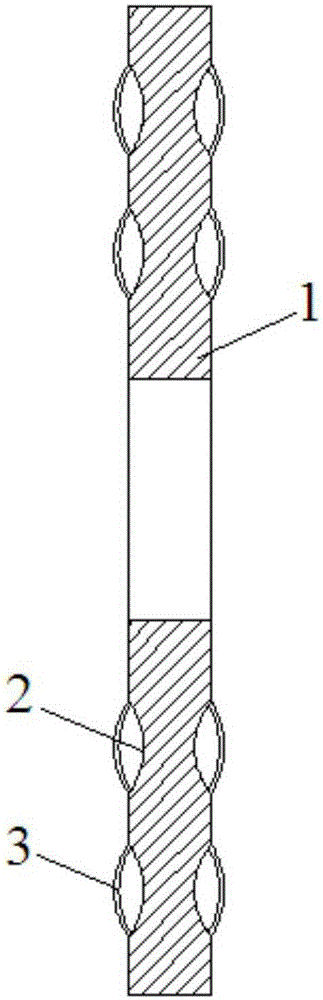

[0010] see figure 1 , a clutch driven disc damping ring, including a damping ring body 1 located between the disc hub and the damping disc, the two sides of the damping ring body 1 are respectively provided with a plurality of grooves 2, located on the same side The grooves are annularly distributed on the surface of the vibration damping ring body, and the notches of the plurality of grooves 2 are respectively installed with arc-shaped elastic sheets 3 that bulge outwards.

[0011] In the present invention, the vibration damping ring body 1 adopts a rubber ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com