Press type valve element

A press-type, spool technology, applied in the direction of valve device, fluid distribution valve, function valve type, etc., to achieve the effect of sensitive rebound, improved operation feel, and excellent feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

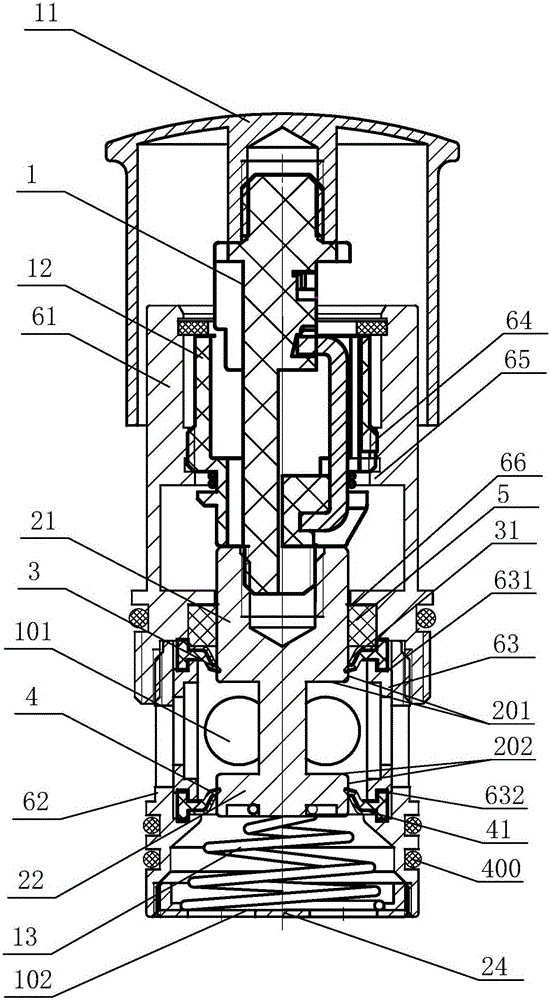

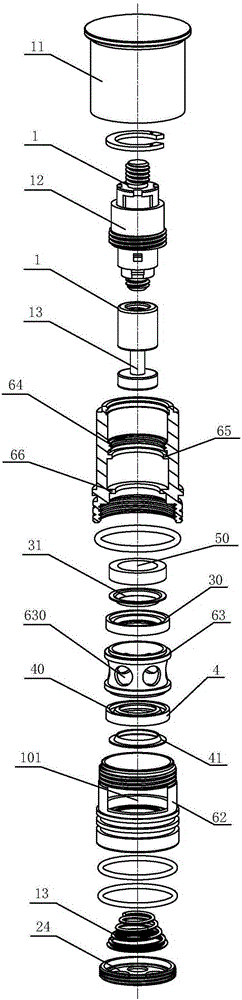

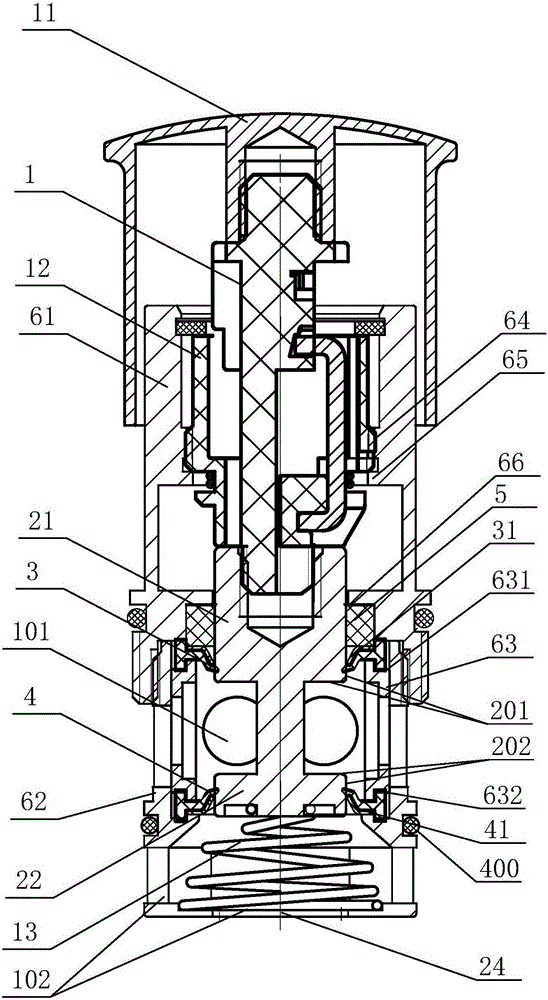

[0024] Refer to attached figure 1 , 2 . The push-type valve core provided by the present invention includes a water inlet 101 and a water outlet 102 .

[0025] The push-type spool is provided with a push-type switch, and the push-type switch is provided with a sliding shaft 1 and provides two stop positions for the sliding shaft 1 in the axial direction. By pressing the switch button 11, the sliding shaft 1 is respectively in the Different stop positions enable the push-type spool to be in the first state of cutting off the communication between the water inlet 101 and the water outlet 102 and the second state of connecting the water inlet 101 and the water outlet 102 respectively. The sliding shaft 1 of the switch can be stretched out from the fixed sleeve 12 of the switch to be connected with the working part of the valve core, that is, the sliding core 2, and the connection method can adopt various methods such as threaded connection, clamping, welding and the like.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com