Preparation method of single-walled carbon nanotube powder

A single-walled carbon nanotube and powder technology, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the problems of low purity and uneven diameter distribution of single-walled carbon nanotubes, and achieve mechanical properties. Enhanced and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment one: the preparation method of a kind of single-walled carbon nanotube powder of this embodiment is carried out according to the following steps:

[0029] 1. In N 2 Under protection, raise the temperature of the reaction chamber to 660°C at a heating rate of 5°C / min, and keep it warm for 45 minutes;

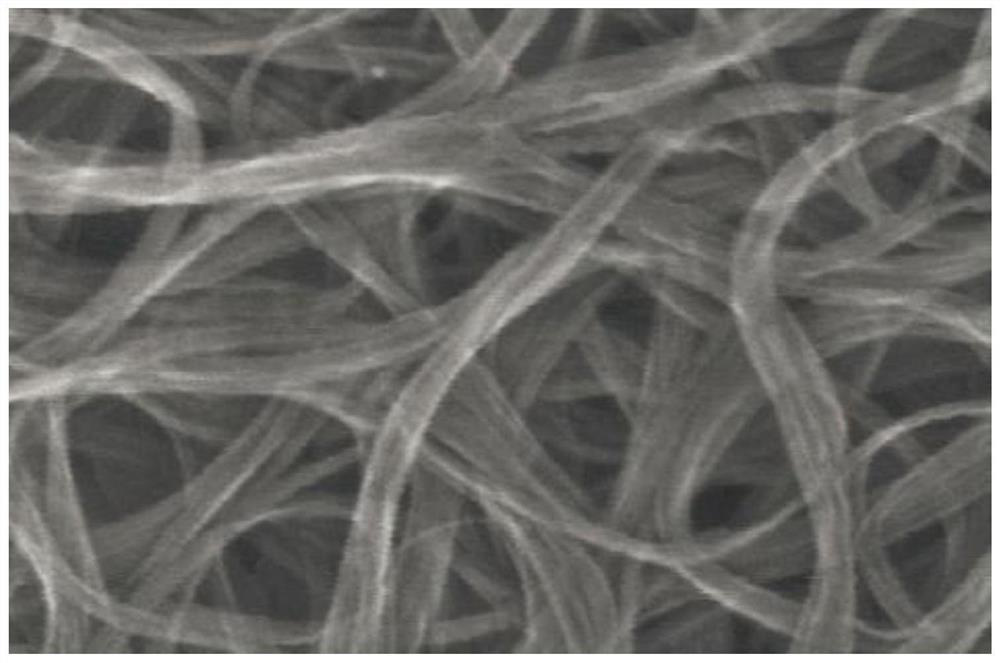

[0030] 2. Continuously feed N into the reaction chamber 2 、H 2 and C 3 h 6 At the same time, the iron plasma is injected into the reaction chamber with an emission current of 5mA. The reaction time is 0.25h, and 232mg of black powder is obtained, that is, single-walled carbon nanotube powder with a diameter of 2.3nm and a carbon content of is 88.50%, and the purity is 86.45%; the N in the mixed gas 2 、H 2 and C 3 h 6 The flow ratio is 3:4:1. The SEM picture of the obtained single-walled carbon nanotube powder is as follows figure 1 shown.

specific Embodiment approach 2

[0031] Specific embodiment two: the preparation method of a kind of single-walled carbon nanotube powder of the present embodiment is carried out according to the following steps:

[0032] 1. Under the protection of Ar, raise the temperature of the reaction chamber to 710°C at a heating rate of 5°C / min, and keep it warm for 50 minutes;

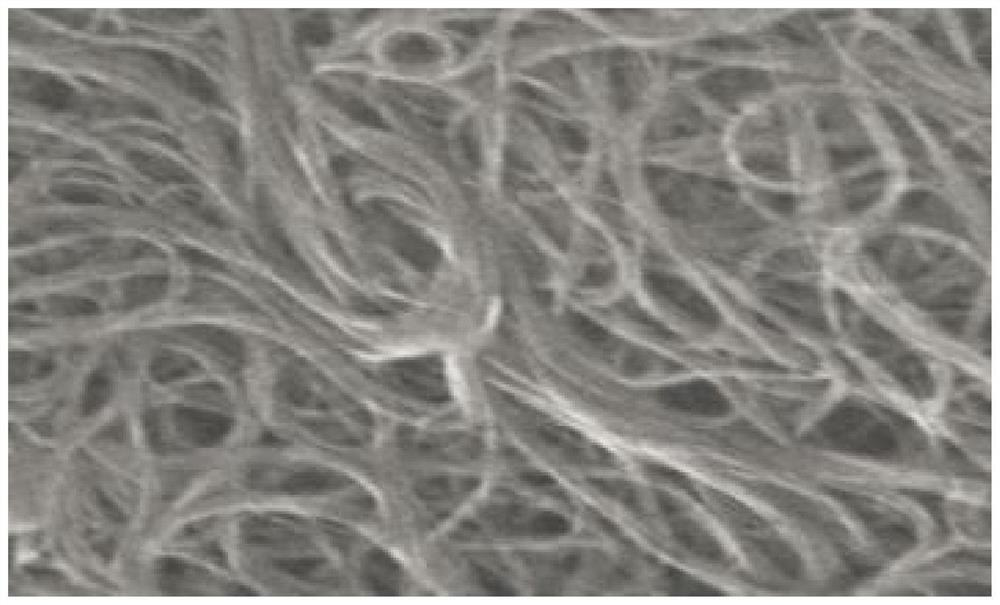

[0033] 2. Continuously feed Ar and H into the reaction chamber 2 and C 3 h 8 At the same time, cobalt plasma is injected into the reaction chamber with an emission current of 8mA. The reaction time is 35min, and 315mg of black powder is obtained, that is, single-walled carbon nanotube powder with a tube diameter of 1.8nm and a carbon content of 86.50%, the purity is 84.25%; Ar, H in the mixed gas 2 and C 3 h 8 The flow ratio is 1.5:2:1. The SEM picture of the obtained single-walled carbon nanotube powder is as follows figure 2 shown.

specific Embodiment approach 3

[0034] Specific embodiment three: the preparation method of a kind of single-walled carbon nanotube powder of this embodiment is carried out according to the following steps:

[0035] 1. Under the protection of Ar, raise the temperature of the reaction chamber to 850°C at a heating rate of 5°C / min, and keep it warm for 40 minutes;

[0036] 2. Continuously feed Ar and H into the reaction chamber 2 and the mixed gas of anhydrous ethanol vaporized at 150°C, inject iron plasma into the reaction chamber with an emission current of 10mA at the same time, and the reaction time is 40min to obtain 504mg of black powder, that is, single-walled carbon nanotube powder , the tube diameter is 2.35nm, the carbon content is 89.35%, and the purity is 86.55%; Ar, H in the mixed gas 2 The flow ratio of absolute ethanol vaporized at 150°C is 1.5:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com