Fuel nozzle and combustion chamber

A technology of fuel nozzles and nozzles, which is applied in the field of aero-engines to achieve the effects of improving heat transfer performance, reducing local irregularities, and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

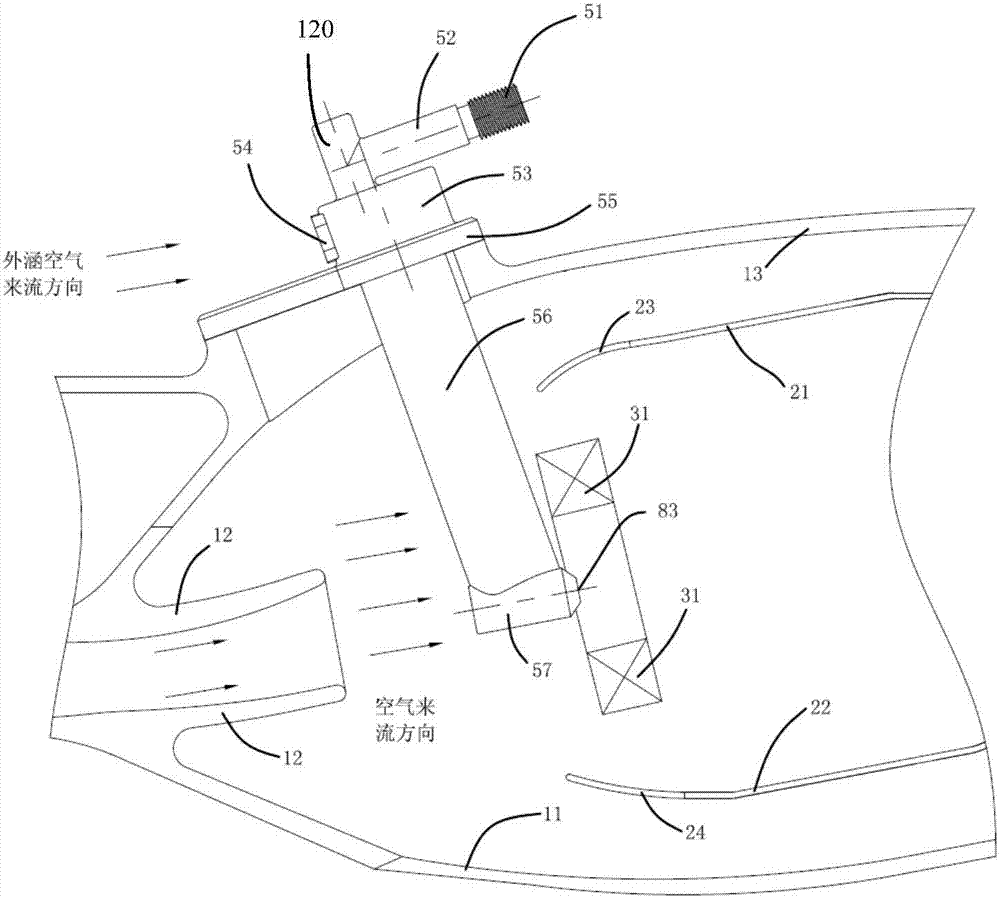

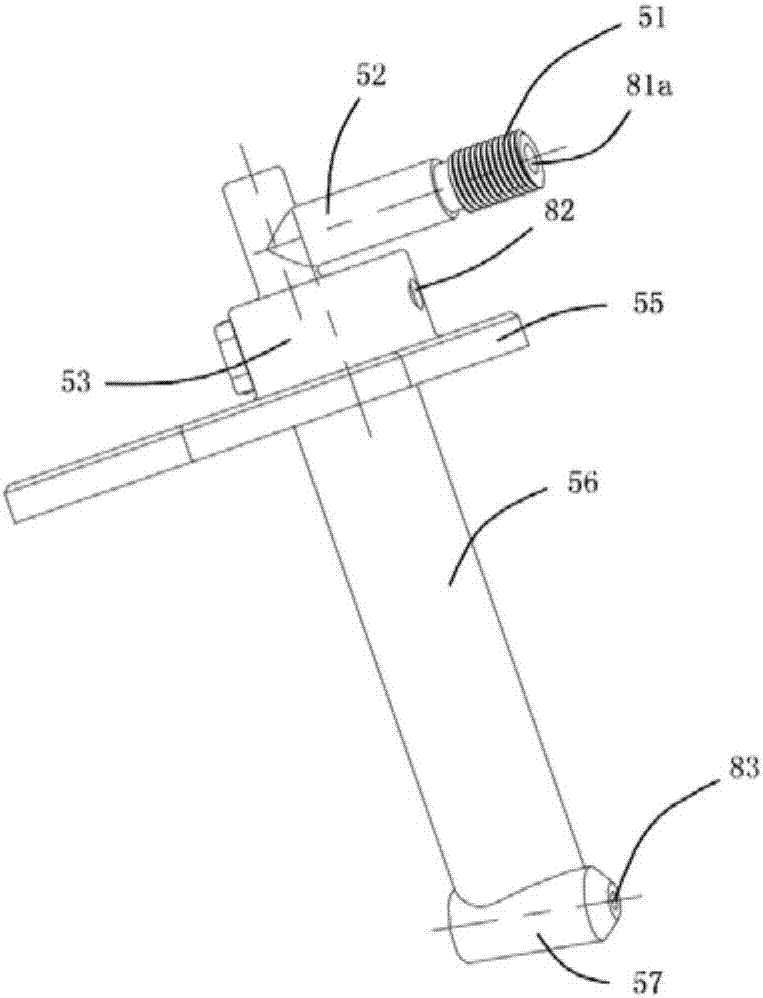

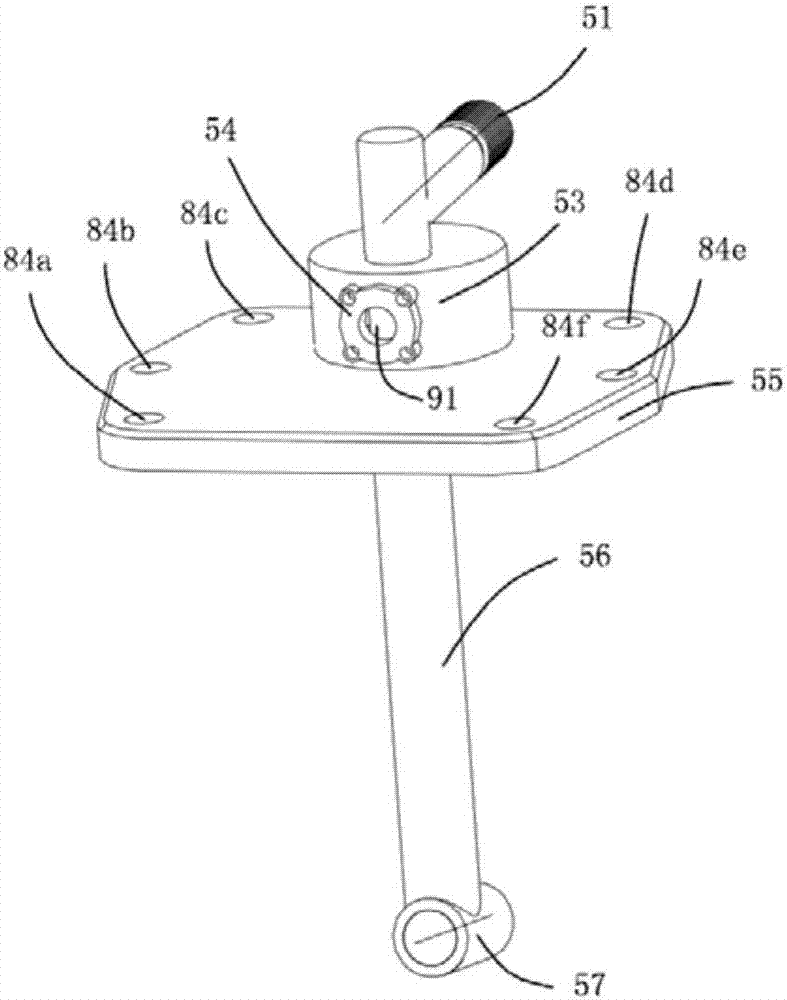

[0064] Combine below Figure 1 to Figure 7 A more detailed elaboration of the technical solution provided by the present invention, a technical solution obtained by replacing any technical means provided by the present invention or combining any two or more technical means or technical features provided by the present invention with each other All should be within the protection scope of the present invention.

[0065] An embodiment of the present invention provides a fuel nozzle, which includes a nozzle inlet portion 120 , a fuel injection rod body 101 , a nozzle head 57 and a decompression housing 56 . The nozzle inlet 120 and the nozzle head 57 are respectively fixed on the two ends of the fuel injection rod body 101; the decompression cover 56 surrounds the outside of the fuel injection rod body 101, and the decompression cover 56 is connected with the nozzle inlet 120 and the fuel injection rod body 101. And at least one of them in the nozzle head 57 is fixed. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com