Feed gas separation method and apparatus of coal gasification apparatus

A separation method and technology for raw gas, which are applied in the field of separation and installation of raw gas from coal gasification units, can solve problems such as increased energy consumption, disadvantage, influence on product synthesis rate, etc. The effect of separating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

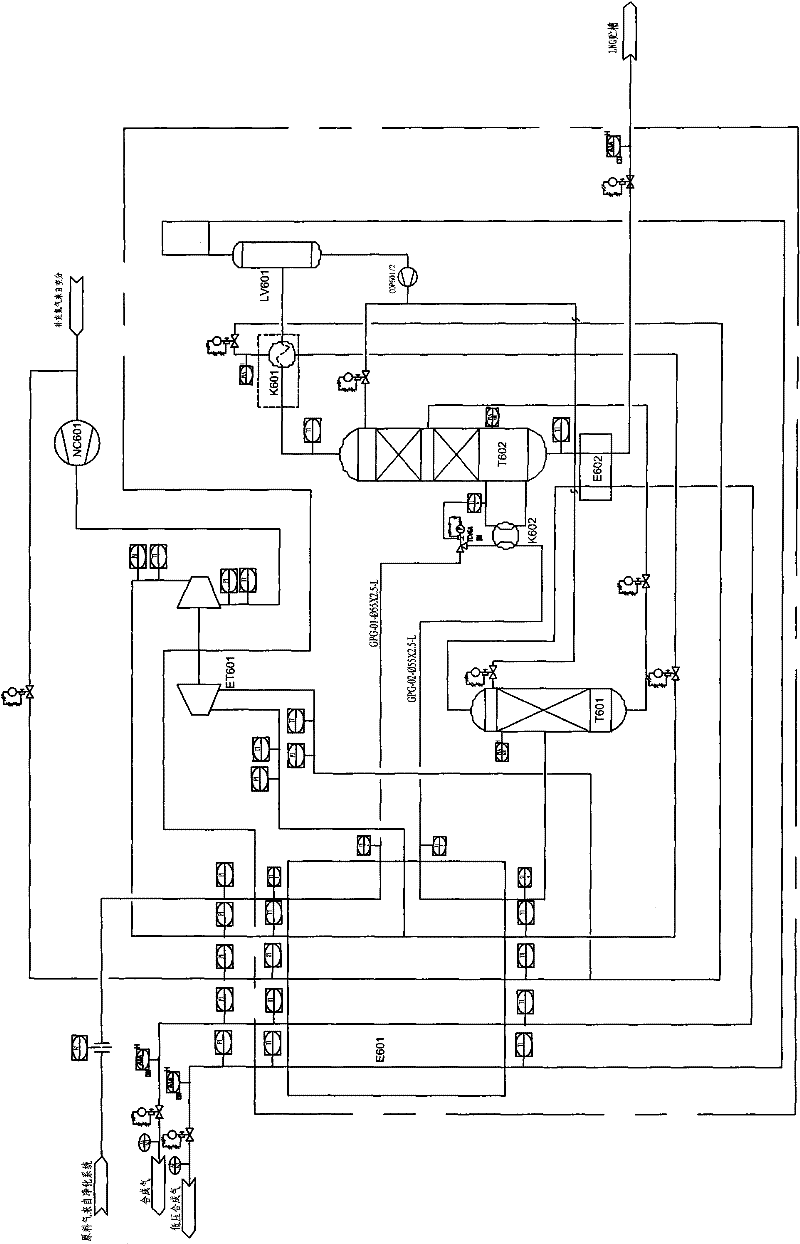

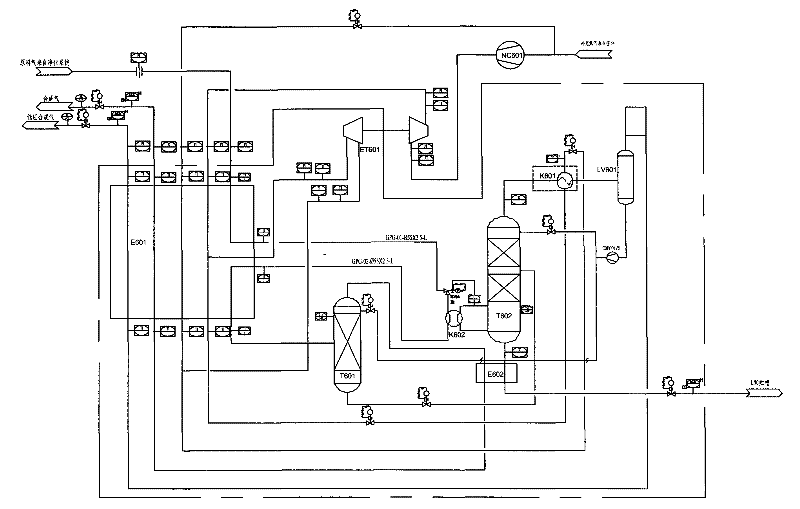

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

[0035] As shown in the figure, the method for separating using the separation device of the present invention includes the following steps:

[0036] (1) The purified raw gas is cooled to -165°C--160°C in the heat exchanger E601;

[0037] (2) The cooled raw gas enters the scrubber T601, and the reflux ratio of the scrubber is controlled to be 0.05-0.1 according to the content of methane in the raw synthesis gas; the higher the methane content, the larger the reflux ratio. When the content is 10%, the reflux ratio is 0.07, and when the methane content is 12%, the reflux ratio is 0.1. to obtain CH at the top of the tower 4 Syngas with content less than or equal to 1%;

[0038] (3) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com