Range hood and method for using the range hood

A technology for range hoods and range hoods, which is applied in the fields of removing range hoods, applications, household stoves, etc., can solve the problem that range hoods have a low rate of removing range hoods, the centrifugal impeller and cavity are greasy and difficult to clean, and range hoods cannot be cleaned synchronously. and other problems to achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

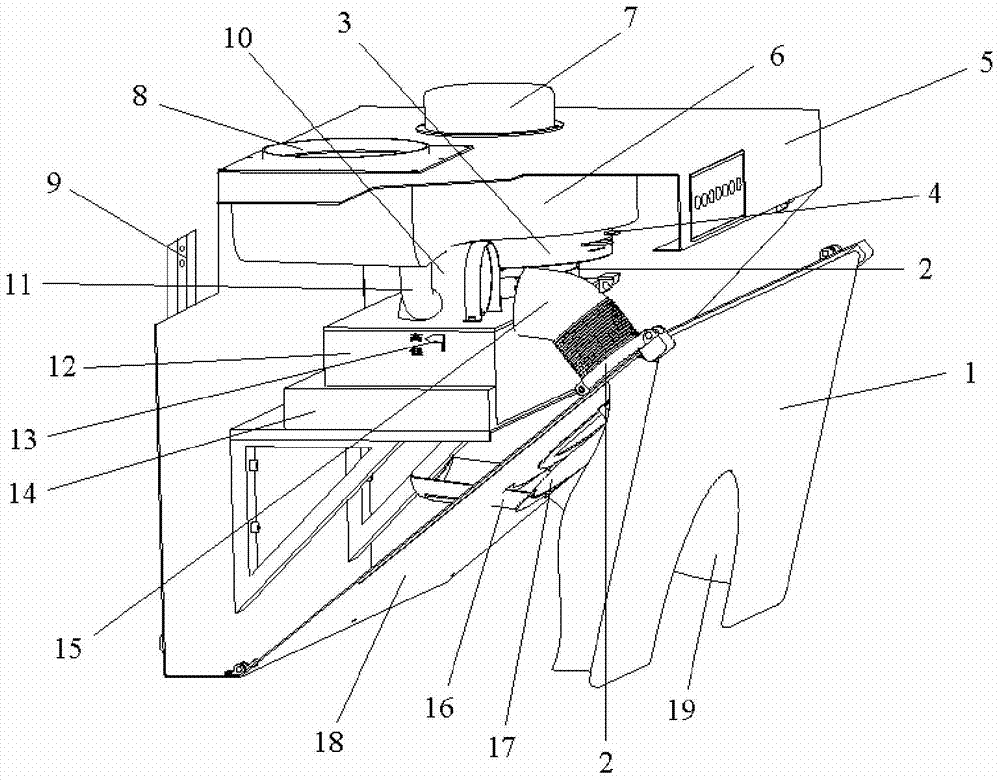

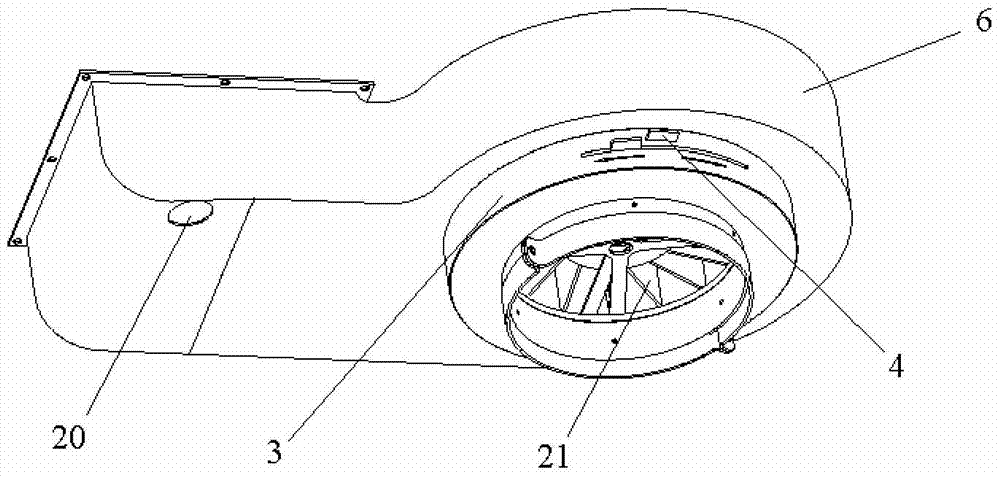

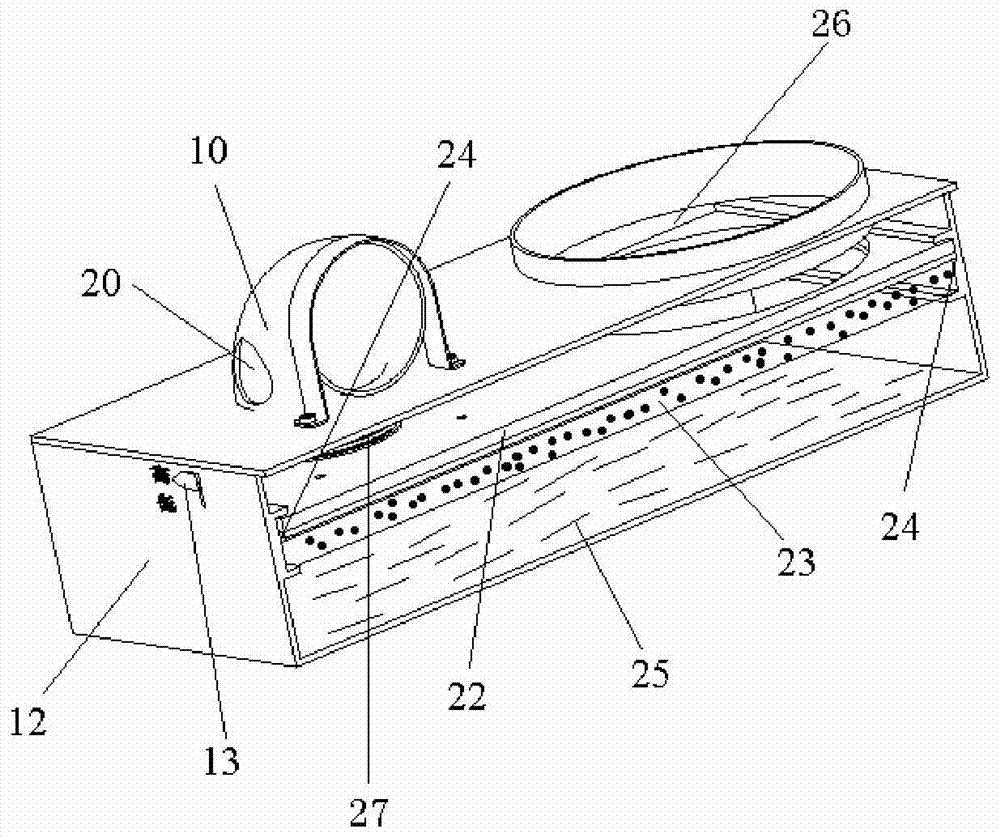

[0023] Please combine Figure 1 to Figure 4 As shown, a range hood of the present invention includes a box body 5, a centrifugal fan 6, a water tank 12 and a front oil collecting part 18, wherein the water tank 12 is embedded in a shock pad 14, and the shock pad 14 is a " "Concave" shaped shock absorber, the size of the recess in the shock absorber 14 is just equal to the size of the water tank 12, the shock absorber 14 can reduce the sound generated when the range hood works, and achieve noise reduction. The centrifugal fan 6 is located in the water tank 12 The top is fixedly connected with the top of the box body 5, the lower end of the centrifugal fan 6 is provided with an adjustment seat 3, and an adjustment block 4 is installed on the adjustment seat 3. The air volume of the centrifugal fan can be adjusted by adjusting the adjustment 4, which can be adjusted appropriately according to the needs. The front oil collecting part 18 is arranged on the inclined surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com