Electric heating type warmer

A heater and electric heating technology, applied in the field of electric heating heaters, can solve the problems of waste of resources, low heating efficiency, large current flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

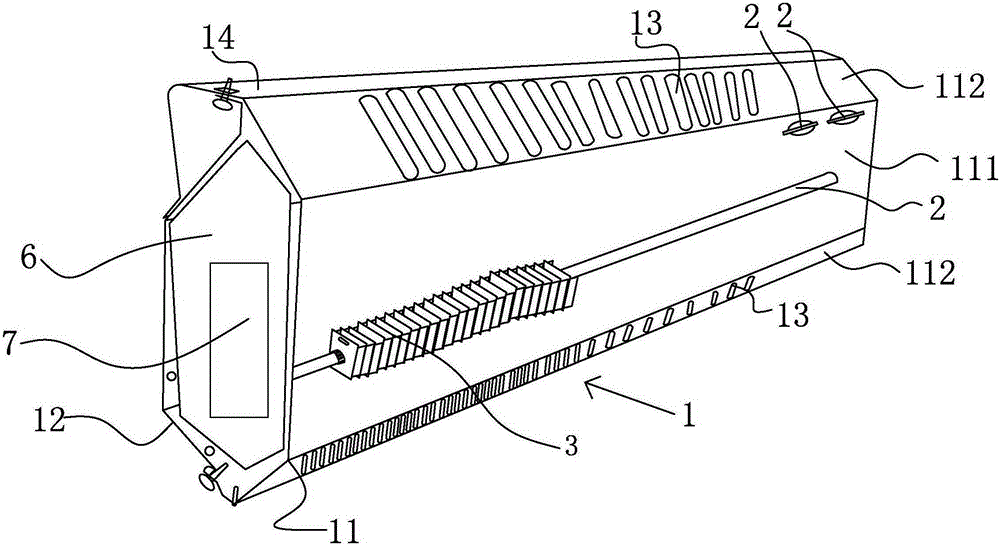

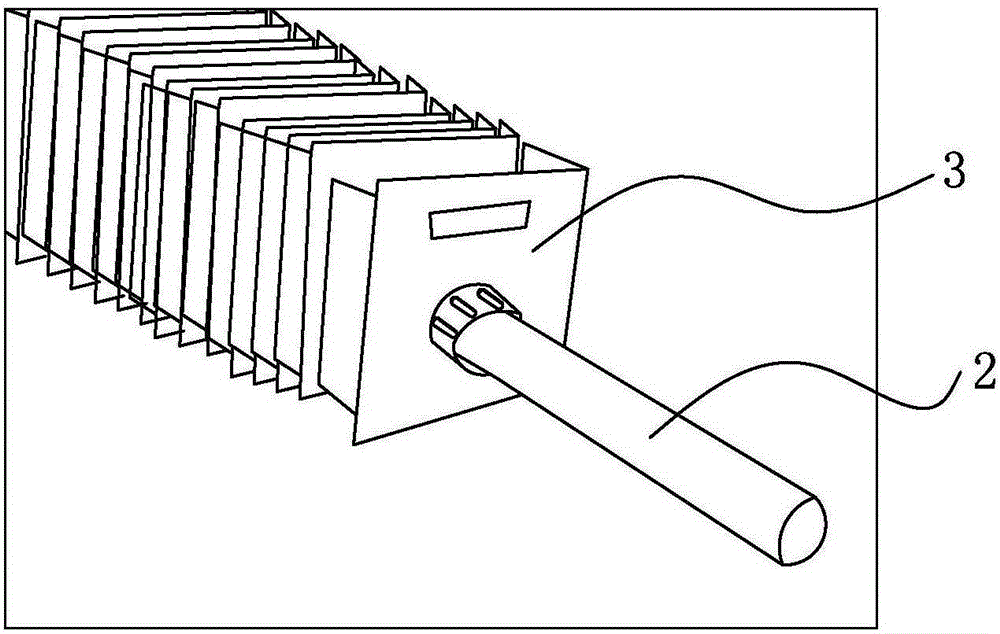

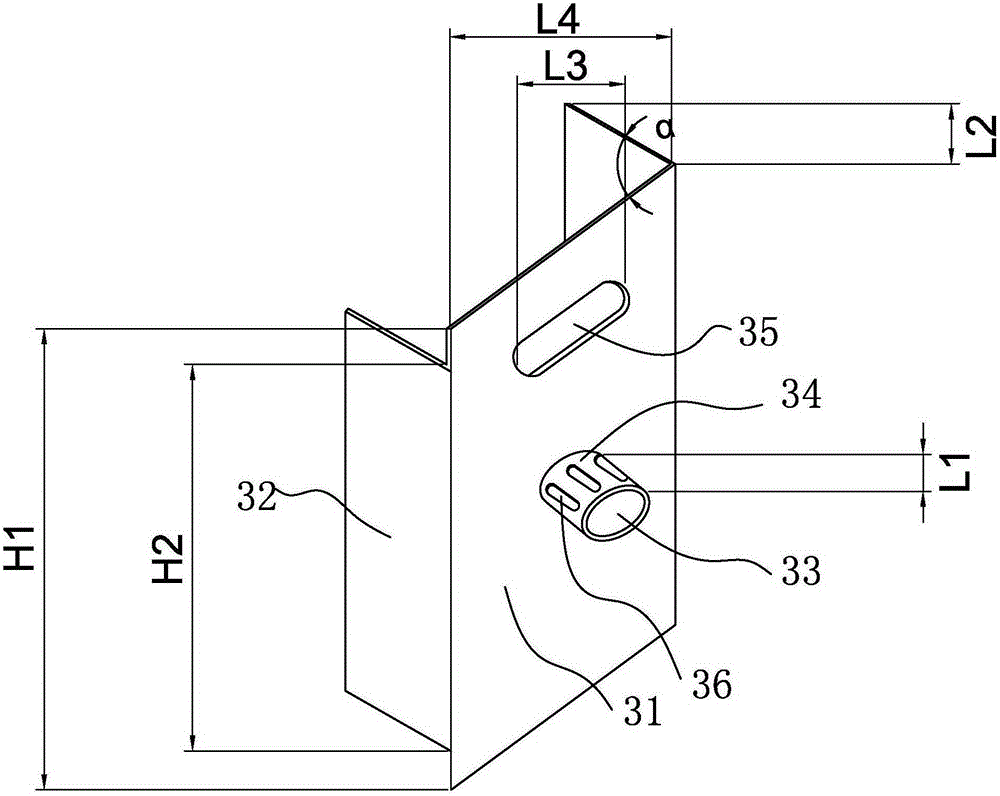

[0020] Below in conjunction with accompanying drawing, electric heating type heater is described further, makes this scheme more clearly.

[0021] Such as Figure 1-3 As shown, the electric heater includes a hollow shell 1, an electric heating tube 2 arranged inside the shell 1, a plurality of heat dissipation fins 3 are sleeved on the electric heating tube 2, and an input switch 4 and an output switch 4 on the front of the shell are provided. Switch 5, the upper and lower parts of the housing 1 are respectively provided with a row of air holes 13 for gas circulation; the cooling fins 3 are composed of a main body 31, flanges 32, flanges 34, and oblong holes 35, and the middle part of the main body has a through hole 33 A flange 34 is disposed on the through hole 33 , and flanges 32 are disposed at both ends of the main body 31 and the direction of the flange is opposite to that of the flange 34 . A plurality of cooling fins are sleeved and installed on the electric heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com