Rapid plate load testing instrument

A flat load and tester technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of increasing the influence of human factors, unable to maintain constant pressure, inaccurate flat load test results, etc., and achieve accurate and objective results , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

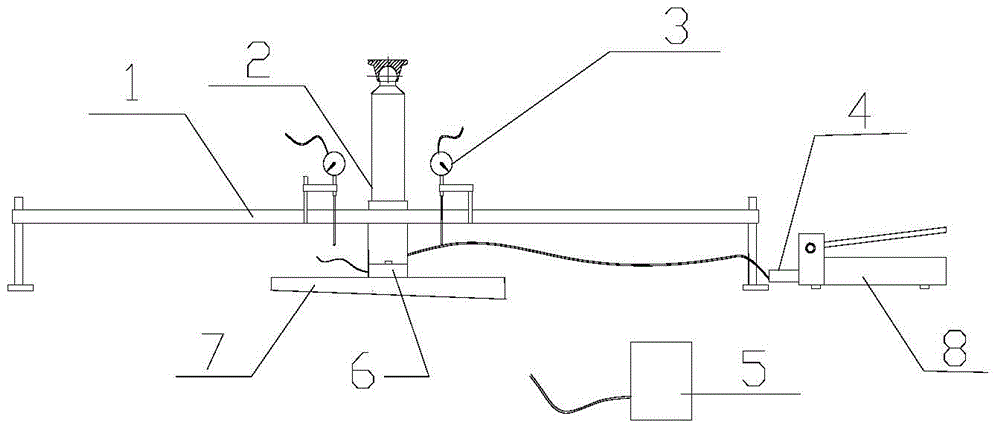

[0019] Such as figure 1 As shown, the basic steps for testing with a fast plate load tester are as follows:

[0020] 1. Select test points on the subgrade surface to be tested.

[0021] 2. Assemble the instrument, fix the displacement test device on the bracket of the measuring bridge, and the probe of the displacement test device is in contact with the top surface of the bearing plate. The bearing plate is directly placed on the subgrade surface without leveling in advance, and the pressure test device and the oil cylinder of the jack are placed in sequence on the upper part. The data processing device is respectively connected with the displacement testing device, the pressure testing device and the control valve of the jack.

[0022] 3. Carry out a loading or unloading test. During the test, when the pressure point required by the regulations is reached, the data processing device closes the control valve to maintain a constant pressure state.

[0023] 4. When the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com