Automatic turning device for photolithography mask

A technology of automatic flipping and photolithography, which is applied in the direction of optics, photographic plate-making process of pattern surface, and originals for photomechanical processing, etc. The version has problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

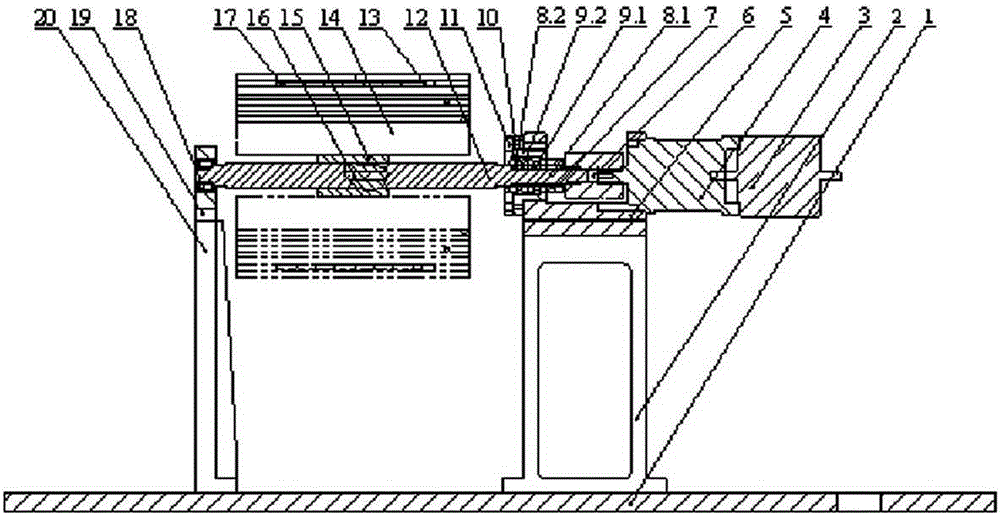

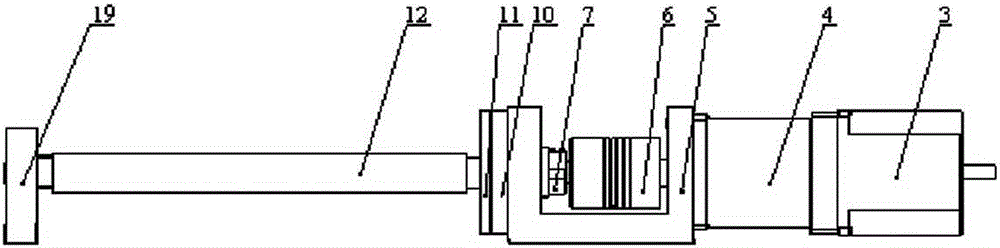

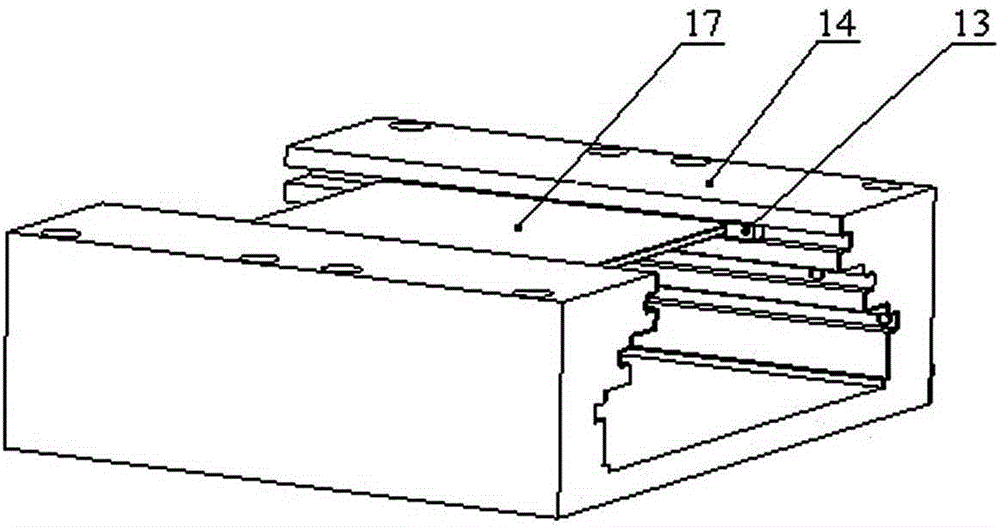

[0016] Such as Figure 1-Figure 4 As shown, the photolithographic plate automatic turning device of the present invention includes a platen 1 . A support group 2 and a vertical plate 20 are fixed on the platform 1 . The upper end of the support group 2 is fixed with a support 5 . The right end of the support 5 is fixed with a reducer 4, and the left end is equipped with a bearing seat 10. The input end of the reducer 4 is connected with the drive unit 3 , and the output end is connected with the drive shaft 12 through the coupling 6 . In order to eliminate the axial clearance, the bearing seat 10 is equipped with a No. I angular contact ball bearing 9.1 and a No. II angular contact ball bearing 9.2. No. I angular contact bearing 9.1 is positioned by No. I inner spacer ring 8.1, lock nut 7, jacking screw and bearing seat 10 through the inner ring of the bearing. The bearing outer ring of the No. II angular contact ball bearing 9.2 is positioned by the No. II inner spacer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com