Heat dissipation structure of active phased array antenna

A phased array antenna and heat dissipation structure technology, which is applied to antennas, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of phased array antenna heat dissipation, improve heat dissipation efficiency, increase space, and improve heat dissipation The effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

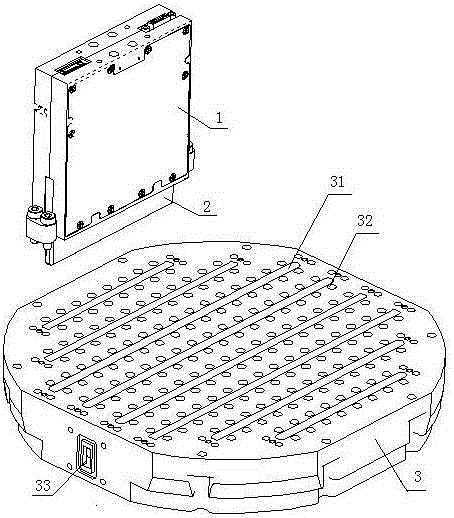

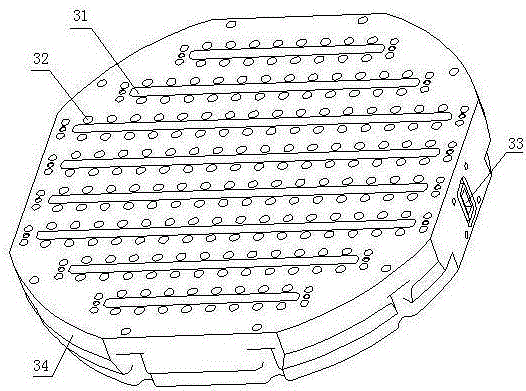

[0028] Example 1: Such as figure 1 , Figure 2a , Figure 2b , Figure 5a , Figure 5b , Figure 5c As shown, this embodiment provides a heat dissipation structure of an active phased array antenna, including two symmetrically arranged T / R assemblies 1 and a heat transfer device 2, a part of the heat transfer device 2 is clamped on the The two T / R assemblies 1 are in close contact with the two T / R assemblies 1 . In this embodiment, the heat transfer device 2 is only attached to the heating area 11 of the two T / R assemblies. The two T / R assemblies 1 are fixedly attached to the heat transfer device 2 through bolts; the other part of the heat transfer device 2 is plugged on a cooling plate 3; the heat transfer device 2 is used to The heat generated by the two T / R assemblies 1 is transmitted to the cooling plate 3 .

[0029] In this embodiment, the heat transfer device 2 adopts a vapor chamber; in this embodiment, the vapor chamber is a vacuum phase change vapor chamber, ...

Embodiment 2

[0035] Example 2: In this embodiment, the difference from Embodiment 1 is that the flow channel inlet 332 and the flow channel outlet 333 are located on the same side of the cooling plate.

Embodiment 3

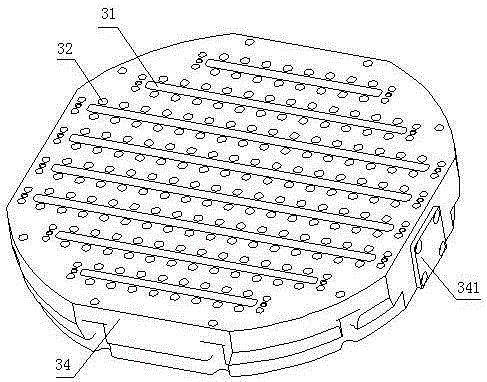

[0036] Example 3: Such as Figure 4As shown, in this embodiment, the difference from Embodiment 1 is that the flow channel 33 is not provided with a flow channel inlet 332 or a flow channel outlet 333, which is only a flow channel body 331 disposed inside the cooling plate body 34 , which is parallel to the upper and lower surfaces of the cooling plate body 34 and surrounds all the slots 31 , so as to cool down the temperature chamber inserted in the slots 31 .

[0037] In this embodiment, the cooling plate directly encapsulates the phase change material in the flow channel body 331 in the cooling plate during production, and the phase change material in the flow channel body 331 is added to the cooling plate itself, whether it is testing or formal use. The T / R assembly is cooled by changing the heat capacity of the material, instead of using an external cooling device to cool the flow channel body in liquid phase or gas phase during the test as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com