Lead wire cover and its installation method

A technology for lead-out wires and mounting ports, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as unfavorable welding operations, narrow space for lead-out wire covers, and easy to fall off screws, etc., to ensure sealing Sexuality, avoiding insufficient strength, and facilitating assembly and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

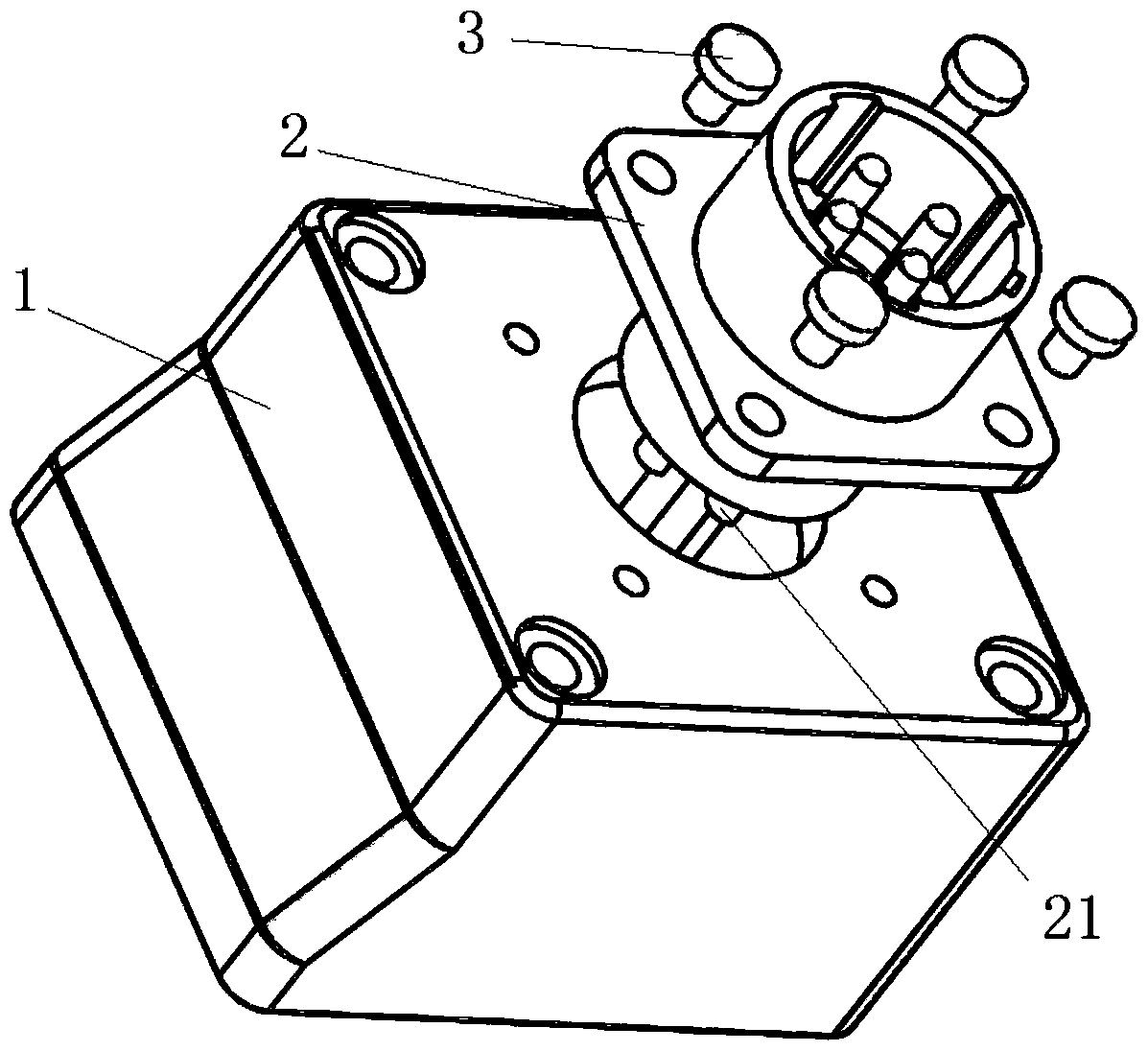

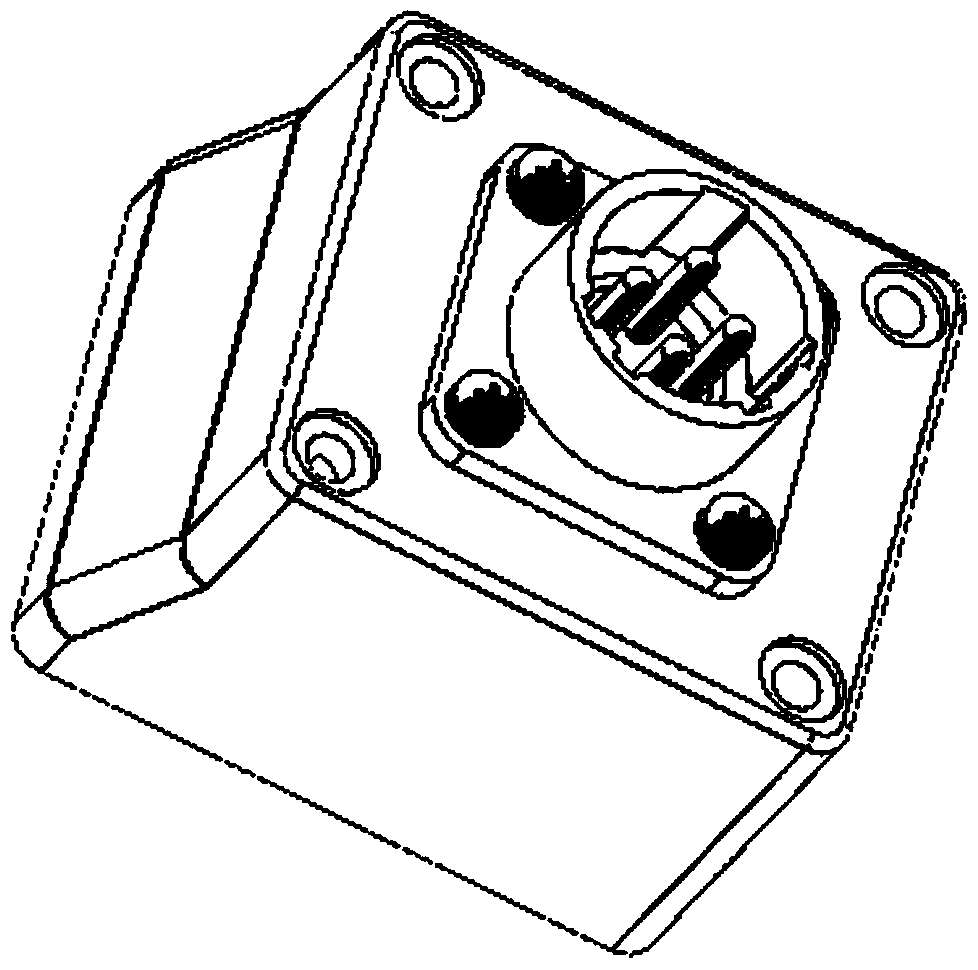

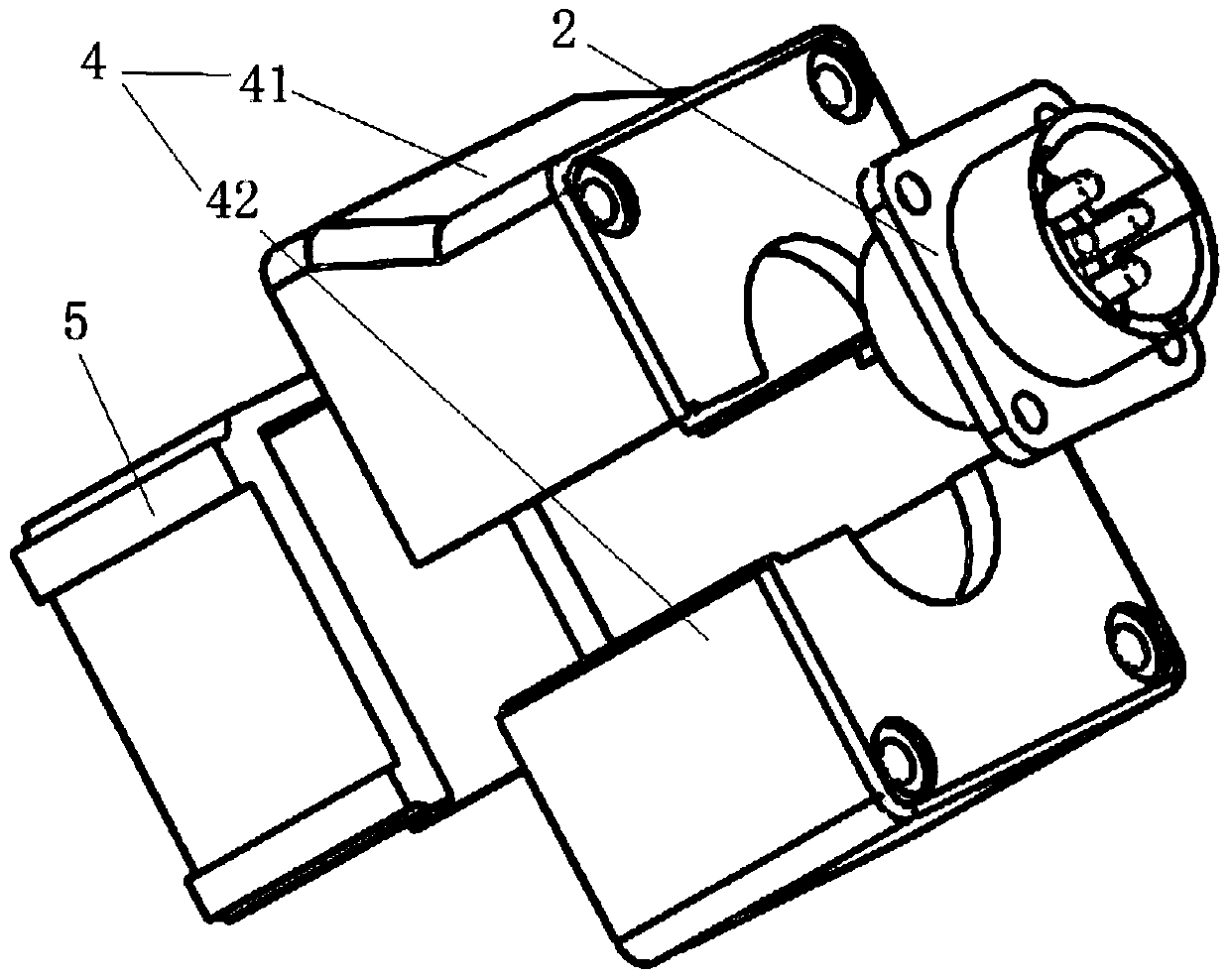

[0042] This embodiment provides a lead-out cover, which is used to install the power connector on the motor, such as Figure 3 to Figure 5 As shown, the lead wire cover of this embodiment includes a cover body 4 and a fixing frame 5 . Wherein, an installation opening for installing the power connector 2 is opened on the cover body 4 , and the installation opening communicates with the accommodating space in the cover body 4 . The fixing frame 5 is arranged in the cover body 4 and cooperates with the cover body to fix and install the power connector 2 on the lead wire cover.

[0043] The lead-out cover provided by this embodiment does not need to use screws to fix the power connector on the lead-out cover, and only through the cooperation of the fixing frame and the cover body, the power connector can be fixed on the lead-out cover, thus avoiding the need for prior art Due to the use of screws to fix, there is a hidden danger that the strength of the lead-out cover is insuffic...

Embodiment 2

[0054] Preferably, this embodiment provides a lead wire cover. On the basis of the above embodiments, the cover body 4 in the lead wire cover of this embodiment is formed by connecting at least two parts. Wherein, when at least two parts are connected together, an installation opening as described above is formed at the joint. Preferably, the cover body 4 of this embodiment is formed by connecting the first part 41 and the second part 42, such as Figure 3-7 shown.

[0055] The cover body of the lead wire cover provided in this embodiment adopts a split structure (that is, consists of at least two parts), so that when the motor lead wire is welded, it is not necessary to pass the motor lead wire through the lead wire cover in advance, and then connect to the power supply Weld the terminals of the power connector; but only directly weld the lead wires of the motor and the terminals of the power connector, then assemble the lead wire cover with the power connector, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com