Combined generator

A generator and composite technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of long installation distance between water turbine or steam engine and generator, inability to make full use of water or steam impact energy, and incomplete transmission of kinetic energy and other problems, to achieve the effects of avoiding current leakage, compact structure, and full power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

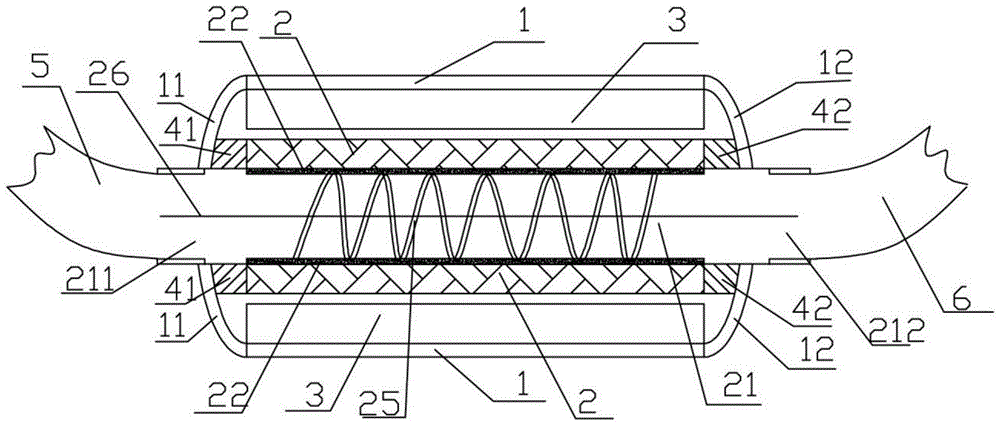

[0034] Such as figure 1 As shown, a compound generator in this embodiment includes a generator body, and the generator body includes:

[0035] Shell 1, such as figure 1 As shown, the casing 1 is a bottomless cylindrical structure, and the two ends of the casing 1 of the cylindrical structure are also provided with a first end cap 11 and a second end cap 12, the first end cap 11 and the second end cap 12 are The annular plates with the same structure, the first end cover 11 and the second end cover 12 are parallel to each other and cover the two ends of the opening of the shell 1 .

[0036] Bearing set 4, such as figure 1 As shown, the bearing set 4 includes a first bearing 41 and a second bearing 42 with the same structure, and the first bearing 41 and the second bearing 42 are symmetrically arranged on the inner walls of the two open ends of the housing 1 .

[0037] Rotor 2, such as figure 1 As shown, the rotor 2 is socketed in the casing 1 of the cylindrical structure, s...

Embodiment 2

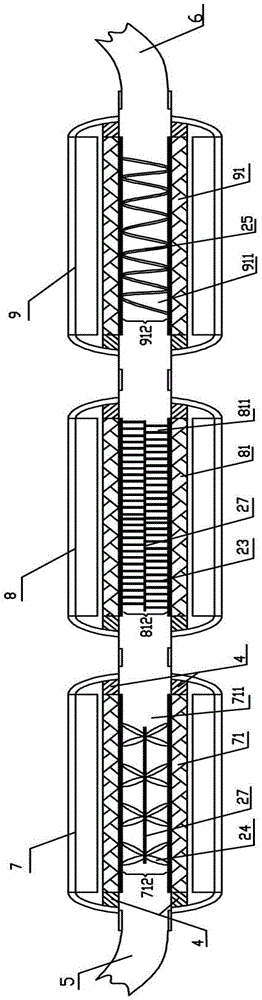

[0044] The compound generator of this embodiment includes multiple generator bodies, and the multiple generator bodies all adopt the structure of the generator body in Embodiment 1. A plurality of generator bodies in this embodiment are sequentially connected between the intake pipe 5 and the outlet pipe 6 of water or water vapor, and the passages 21 of the rotor 2 in each generator body communicate with each other; from the inlet pipe 5 to the outlet pipe 6 direction, The guide area of the guide part on the rotor 2 in each generator body decreases successively.

[0045] Specific as figure 2 As shown, the composite generator formed by the combination of multiple generator bodies in this embodiment includes three generator bodies, which are respectively the first generator body 7, the second generator body 8 and the third generator body 9 , the first generator body 7 includes a first rotor 71, and the first rotor 71 includes a first channel 711 and a first guide portion 712...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com