Probe light homogenizing system and probe light homogenizing method of random reflection surface speed interferometer

A reflective surface and interferometer technology, which is applied in the field of laser detection, can solve the problems of the reduction and increase of laser energy utilization, and achieve the effects of controllable illumination area size, uniform spot distribution and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

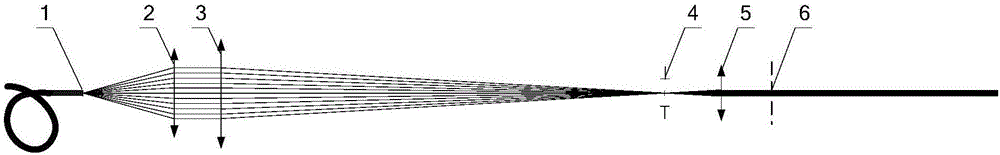

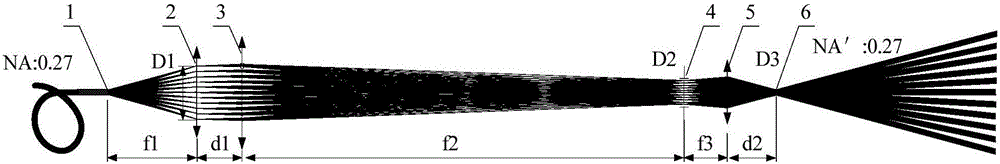

[0050] figure 2 It is a schematic diagram of the effect of obtaining a parallel beam with a diameter of φ1mm after the beam of numerical aperture NA=0.27 emitted from the center point of the fiber end face 1 passes through the homogenization system. figure 2 The parameters in are:

[0051] f 1 - the focal length of the collimating lens 2;

[0052] d 1 - the distance between the collimator lens 2 and the front group 3 of the reducer;

[0053] f 2 - the focal length of the front group 3 of the beam reducer;

[0054] f 3 - the focal length of group 5 after the reducer;

[0055] d 2 - the distance between the beam reducer group 5 and the virtual fiber end face 6;

[0056] NA-Numerical aperture of the beam at fiber end face 1;

[0057] NA' - the numerical aperture of the beam at 6 places on the virtual fiber end face;

[0058] α is the exit half-angle of the exit beam at fiber end face 1;

[0059] NA'=NA=sin α;

[0060] D. 1 - beam aperture after being collimated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com