Energy-saving system and method for power matching between engine and hydraulic pump

An engine and power technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as difficulty in realizing energy saving of excavators, and achieve the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

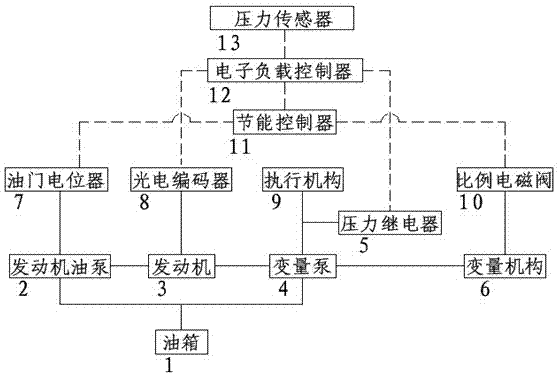

[0046] The present invention will be further described below by taking an excavator as an example.

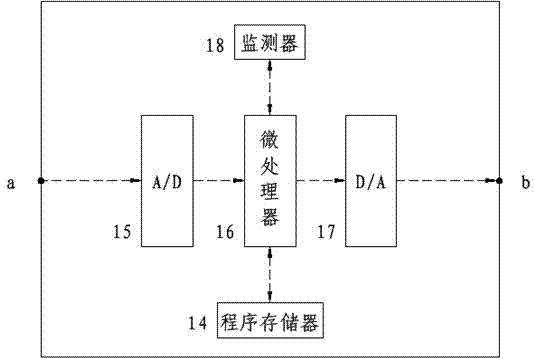

[0047] The pressure sensor 13 is installed inside the bucket of the excavator for real-time detection of the pressure on the inside of the bucket when the excavator is working, that is, the load pressure. The electronic load controller 12 is a PID controller, which is installed in the cab. The pressure sensor 13, the electronic load controller 12 and the energy-saving controller 11 are connected through CAN (controller area network). The pressure sensor 13 receives the pressure signal and converts it into an electrical signal. Send to the electronic load controller 12, the electronic load controller 12 is used to receive the photoelectric encoder 8 and the pressure relay 5 signal, and the energy-saving controller 11 is used to control the operation of the throttle potentiometer 7 and the proportional solenoid valve 10. The throttle potentiometer 7 is installed on the engine oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com