A kind of sludge pre-drying carbonization treatment method

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of lack of water dialysis and removal structure, long water evaporation and drying process, and reduced Drying use efficiency and other issues, to achieve the effect of improving heating and drying efficiency, uniform and thorough dialysis to remove water, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

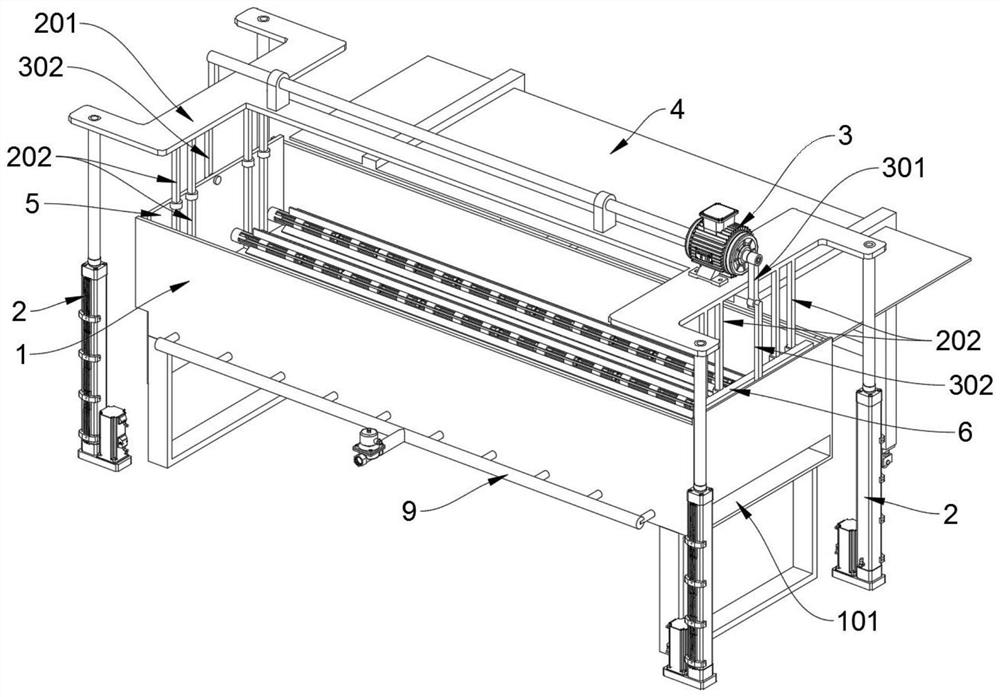

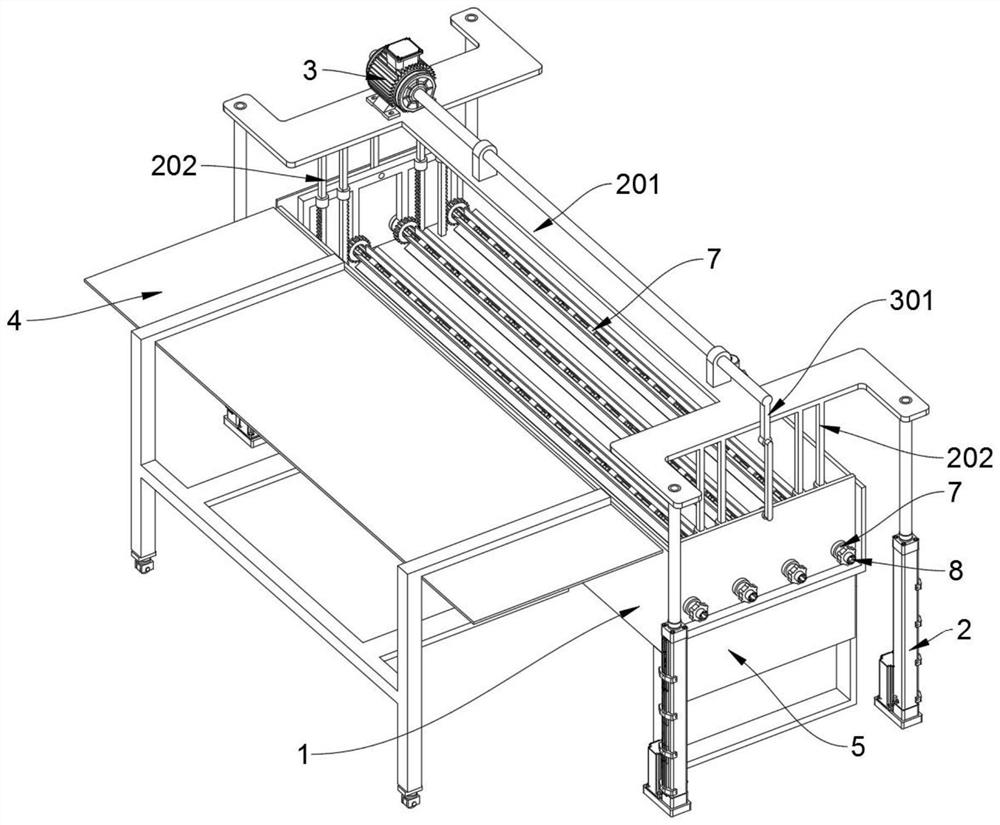

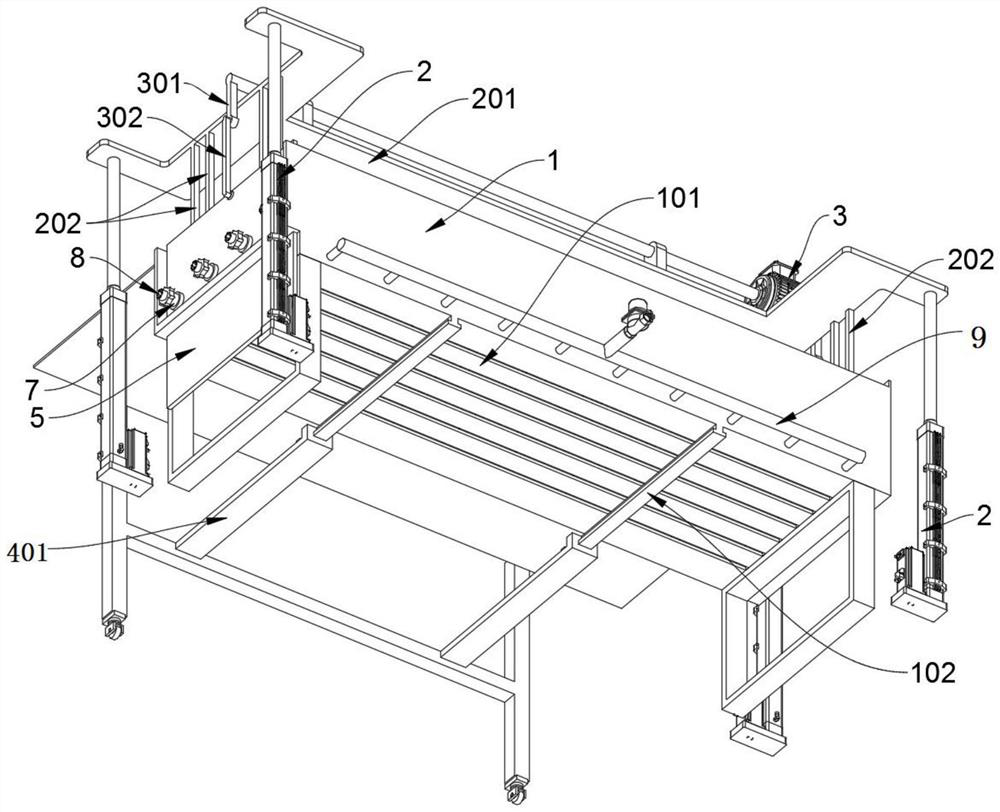

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] see Figure 1 to Figure 8 , an embodiment provided by the present invention:

[0029] A sludge pre-drying carbonization treatment method, the sludge pre-drying carbonization treatment method is completed by the sludge pre-drying carbonization treatment equipment, and then realizes the sludge pre-drying carbonization treatment, comprising the following steps:

[0030] Firstly, slide the inserting puller 5 through the electric push rod 2 and insert it on the rear opening of the drying box 1, then fill the sludge into the drying box 1, and continue to slide down and insert it through the electric push rod 2 after the filling is completed. Pull the block 5 and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com