High-voltage winding type motor brush lifting control system and method

A control system, winding type technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, starter parts, etc., can solve the problem of large carbon brush consumption, carbon powder short-circuit arcing fault , daily maintenance workload and other problems, to achieve the effect of overcoming continuous friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

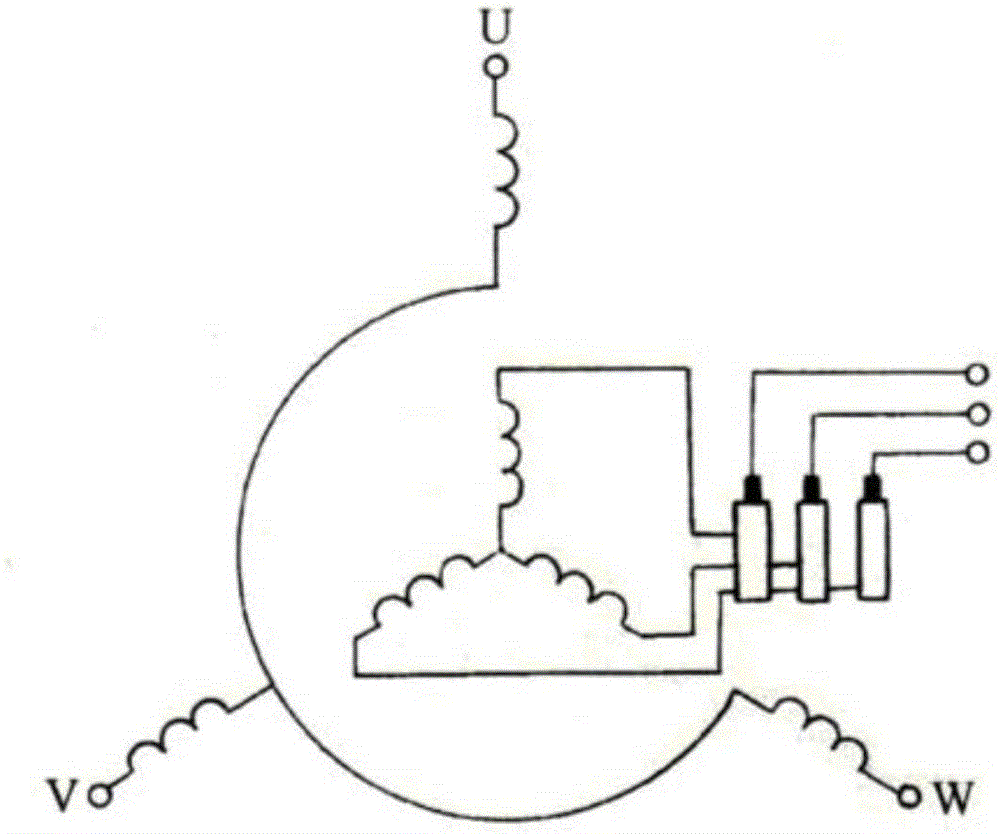

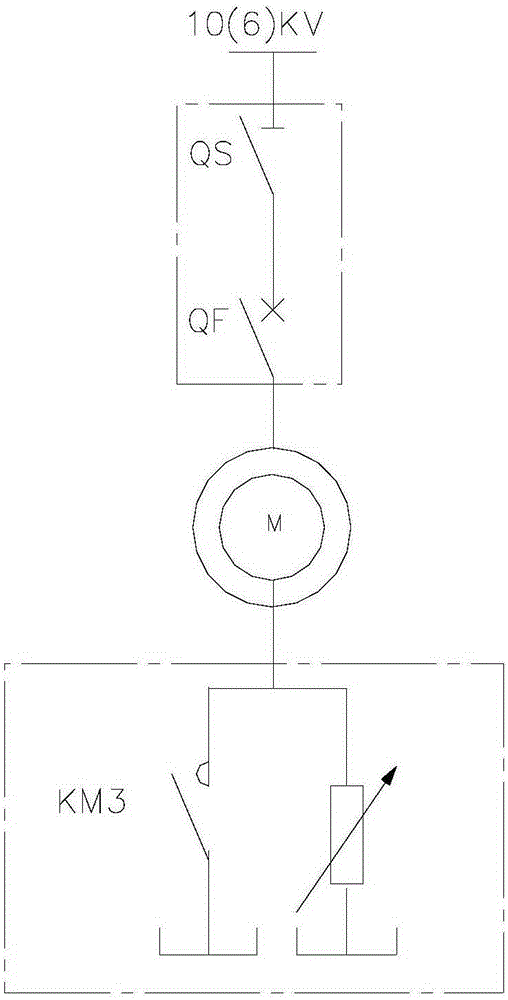

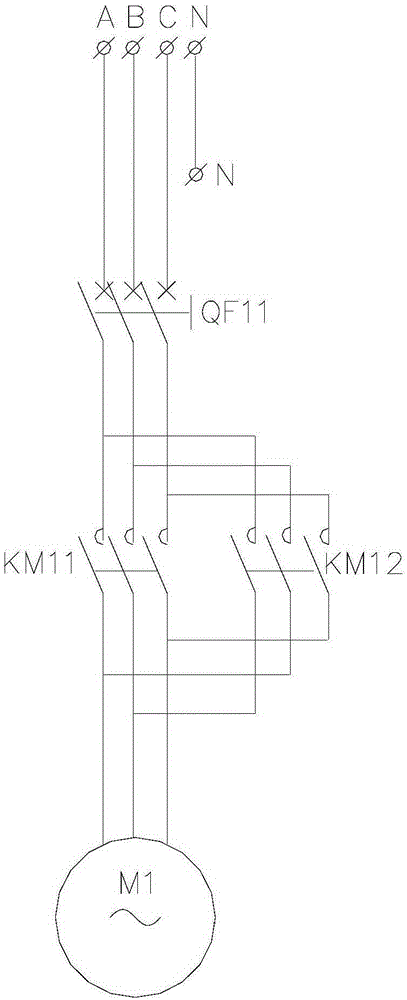

[0053] This embodiment discloses a high-voltage wire-wound motor brush lifting control system, which is characterized in that it includes a first servo motor M1, a second servo motor M2, a collector ring short-circuit switch arranged in the motor rotor circuit, and correspondingly arranged The first proximity switch SX11 and the second proximity switch SX12 at the position where the carbon brush is dropped and lifted correspond to the third proximity switch SX21 and the fourth proximity switch SX22 at the opening and closing positions of the slip ring short-circuit switch, the first Relay K1 and second relay K2;

[0054] The first servo motor is connected to the lifting and falling parts of the carbon brush, the lifting or falling of the carbon brush is controlled by the first servo motor, the second servo motor is connected to the short-circuit switch of the slip ring, and the short-circuit switch of the slip ring is controlled to open or close by the second servo motor;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com