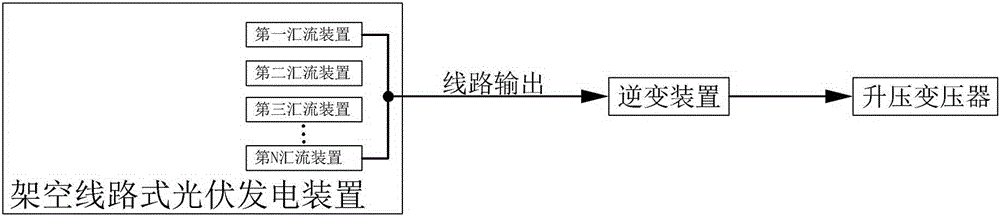

Overhead line type photovoltaic power generation device and power transmission and distribution system

A photovoltaic power generation and overhead line technology, applied in photovoltaic power generation, photovoltaic power stations, photovoltaic modules, etc., can solve the problems of long installation period, high manual installation cost, and large resources, and achieve reduced civil engineering workload, reduced steel consumption, Realize the effect of economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

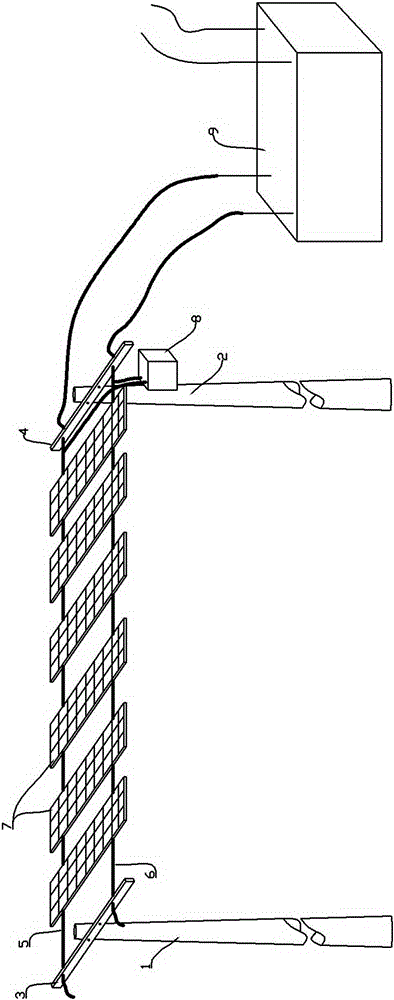

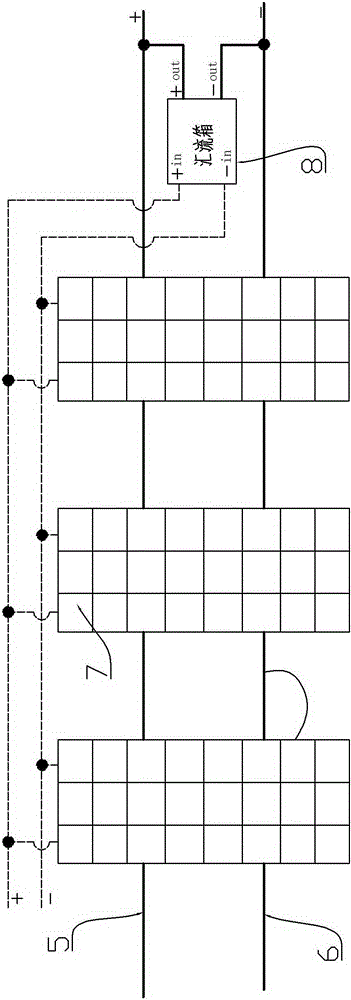

[0044] Embodiment 1: An overhead line type photovoltaic power generation device, see Figure 1 to Figure 5 ; This device includes at least one power generation unit, each power generation unit includes two fixed support parts 1, 2 (the support parts can be utility poles or iron towers or other parts), at least one group of power generation layers, wherein each layer generates electricity It includes at least one photovoltaic module 7, at least two tensile ropes 5, 6 erected in the middle of two supporting parts; the photovoltaic module 7 is arranged on the tensile rope between the two supporting parts, so as to The above-mentioned photovoltaic module 7 is installed overhead, and the light-facing surface of the photovoltaic module 7 is arranged horizontally or inclined.

[0045] For ease of understanding, this embodiment takes one power generation unit as an example for illustration; specifically, the power generation layers in this embodiment are a group, such as figure 1 As ...

Embodiment 2

[0047] Embodiment 2: The same as Embodiment 1 will not be repeated, the difference is: there are multiple power generation units, and the multiple power generation units are connected in series or in parallel via the tension ropes in each power generation unit to form a power generation unit. Unit group; Of course, in order to ensure the safety and stability of this device, each power generation unit should also be equipped with corresponding lightning protection devices, overvoltage protection, overcurrent protection, and related protection devices for maintaining obvious disconnection points, etc. Electrical detection and protection equipment, data acquisition, communication,.

Embodiment 3

[0048] Embodiment 3: see Figure 6 ; The same as Embodiment 2 will not be repeated, the difference is: the power generation layers are two or more groups; and the multiple groups of power generation layers are arranged between two support members from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com