Air jet weaving machine comprising electromagnetic valve

A knitting machine and valve technology, which is applied in the field of knitting machines, can solve the problems of expensive compressed air, etc., and achieve the effects of short response time, reduced losses, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

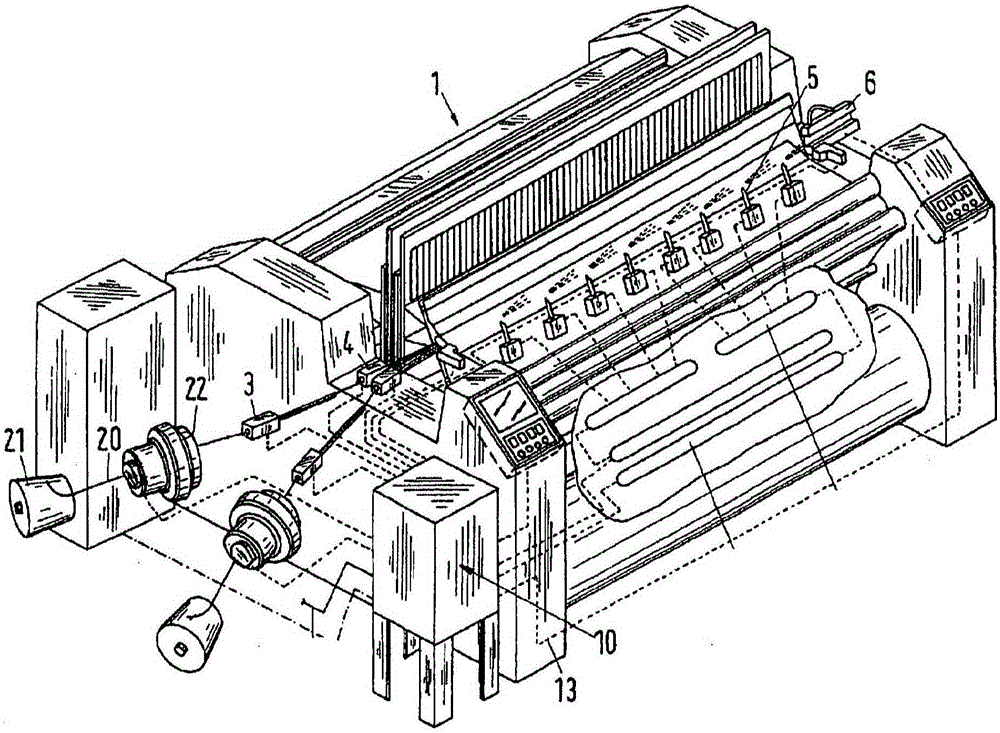

[0026] figure 1 A conventional air-jet knitting machine 1 is shown in . Air jet knitting machines may generally include weft yarn 20 disposed on one or more yarn bobbins 21 . exist figure 1 In the air-jet knitting machine, the weft yarn 20 enters the weft yarn storage device / feeder 22. The weft yarn is picked from the pre-feeder 22 through the main nozzle 4 . The main nozzle 4 can be preceded by one or more pre-nozzles 3 . There can be several pre-nozzles and main nozzles 4 . The nozzles 3 and 4 are supplied with compressed air from the air supply unit 10 through the line 13 . Furthermore, in order to convey the weft thread 20 completely through the shed of the air-jet weaving machine, a relay nozzle 5 may be provided. The relay nozzle is also supplied with compressed air from the compressed air supply unit 10 . Furthermore, one or more stretching nozzles 6 may be provided to ensure that the weft yarn remains stretched until the shed is closed after the weft yarn reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com