Transmission mechanism for semi-automatic powder adding machine

A kind of transmission mechanism, semi-automatic technology, applied in the direction of transmission device, gear transmission device, mechanical equipment, etc., can solve the problems of easy knocking on the surface of the product, difficult control of product quality, high labor cost, etc., to reduce labor cost and work intensity , Strong practicability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

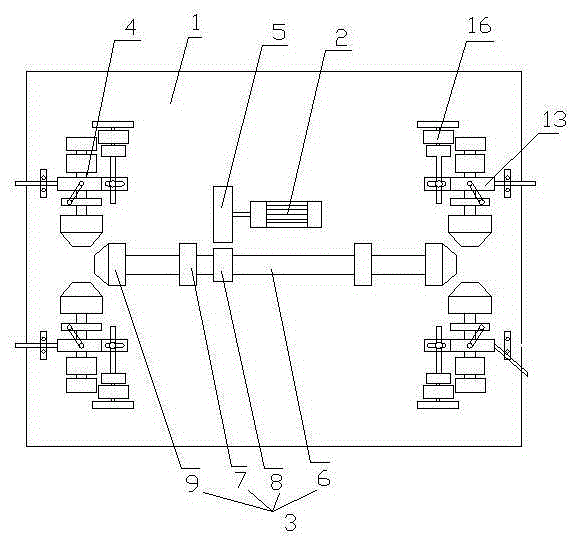

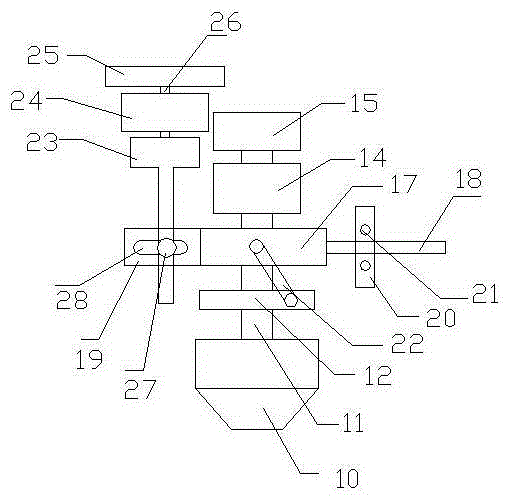

[0018] As shown in the figure, a transmission mechanism for a semi-automatic powder adding machine includes a transmission mechanism base 1, a speed regulating motor 2, a main transmission assembly 3 and four driven assemblies 4, and one end of the speed regulating motor 2 is provided with a driving gear 5, The main transmission assembly 3 includes a main transmission shaft 6, a main bearing housing 7, a driven gear 8 and a driving bevel gear 9, the main transmission shaft 6 is horizontally arranged on the transmission mechanism base 1 through the main bearing housing 7, and the driving umbrella The quantity of gear 9 is two, is arranged on the two ends of main transmission shaft 6 respectively, and driven gear 8 is meshed with driving gear 5 on the speed regulating motor 2;

[0019] The four driven assemblies 4 are arranged symmetrically in pairs at both ends of the main t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com