Rapid mounting tool rest for turning tool

A technology of turning tools and tool holders, which is applied in the direction of tool holders, etc., can solve the problems of different workpiece quality, high labor intensity, and low tool loading efficiency, and achieve the effects of prolonging tool life, reducing labor intensity, and improving tool loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

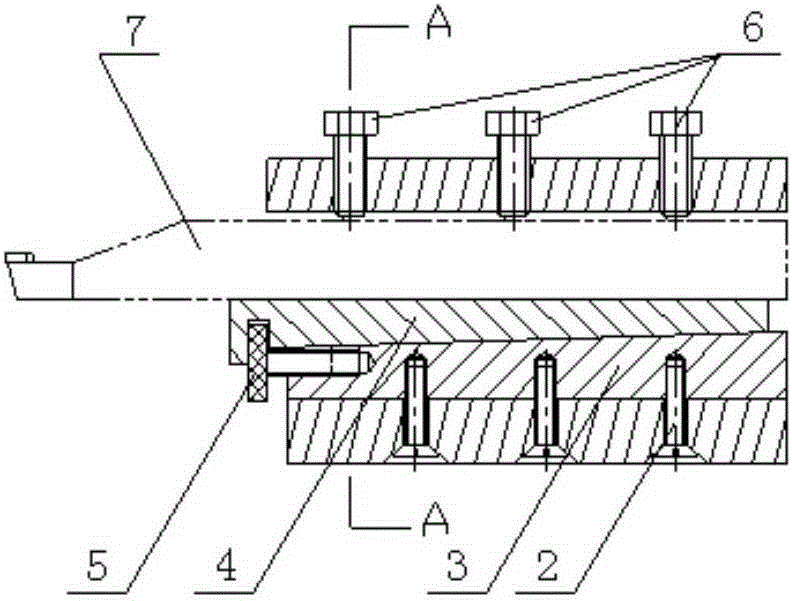

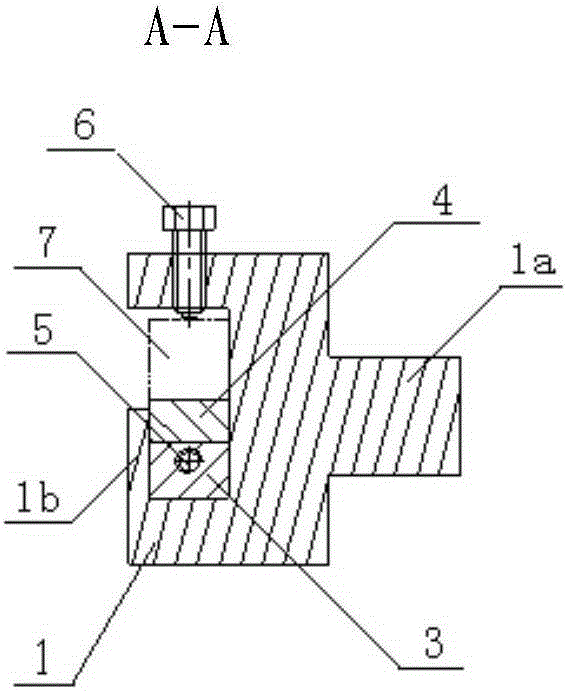

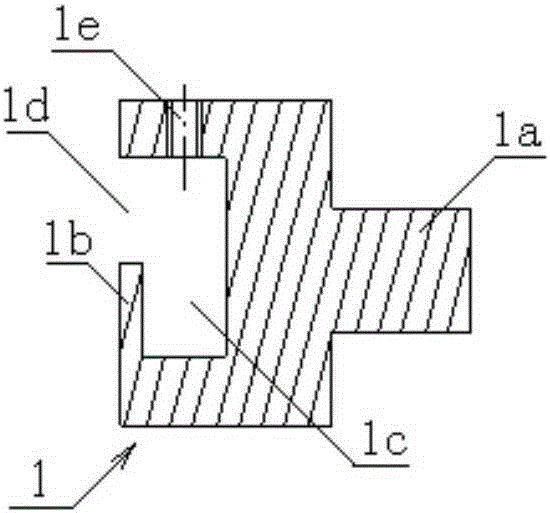

[0013] On the upper surface of the tool rest mounting seat, there are three threaded holes 1e on the body distributed along the length direction of the body 1 and vertically passing through the top surface of the turning tool mounting groove 1c. Bolt 6, on the lower surface of the tool holder mounting seat, there are 3 threaded holes under the countersunk body that are distributed along the length direction of the body 1 and vertically pass through the bottom surface of the turning tool mounting groove 1c. The angle value of the wedge-shaped structure of the static inclined iron 3 is 6°.

[0014] Using the above embodiment to process the cathode inner hole in a Zeeman laser gyro product, the surface roughness Ra value is required to be 0.1 micron. In the mirror lathe, the operator who was originally a highly skilled operator manually installed the turning tool and repeatedly tried cutting , Adjust the shim, and try cutting again, it takes more than 20 hours (3 days), the effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com