Die cutting machine die set used for sheets and formed finished products of plates

A sheet metal forming and punching machine technology, which is applied in the field of finished punching machine formwork, can solve problems such as not being able to meet the mold discharge requirements, and achieve the effect of simple structure, remarkable effect and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

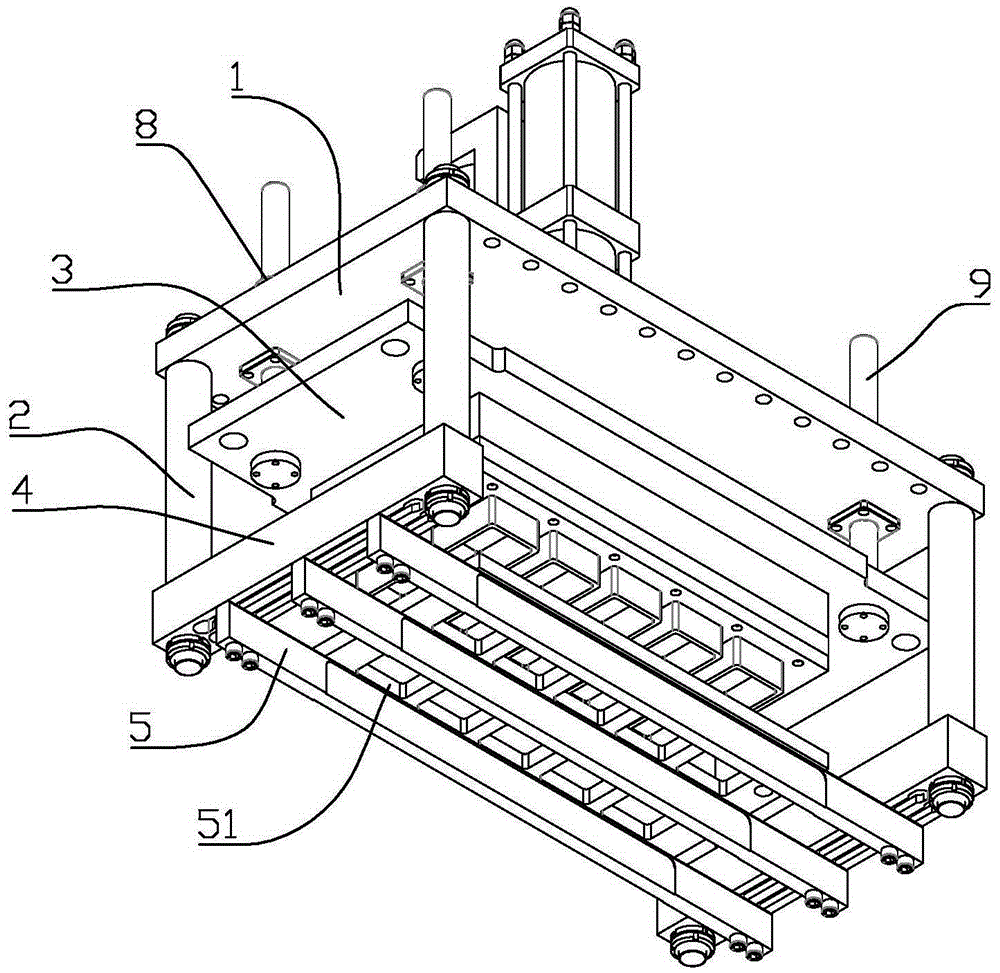

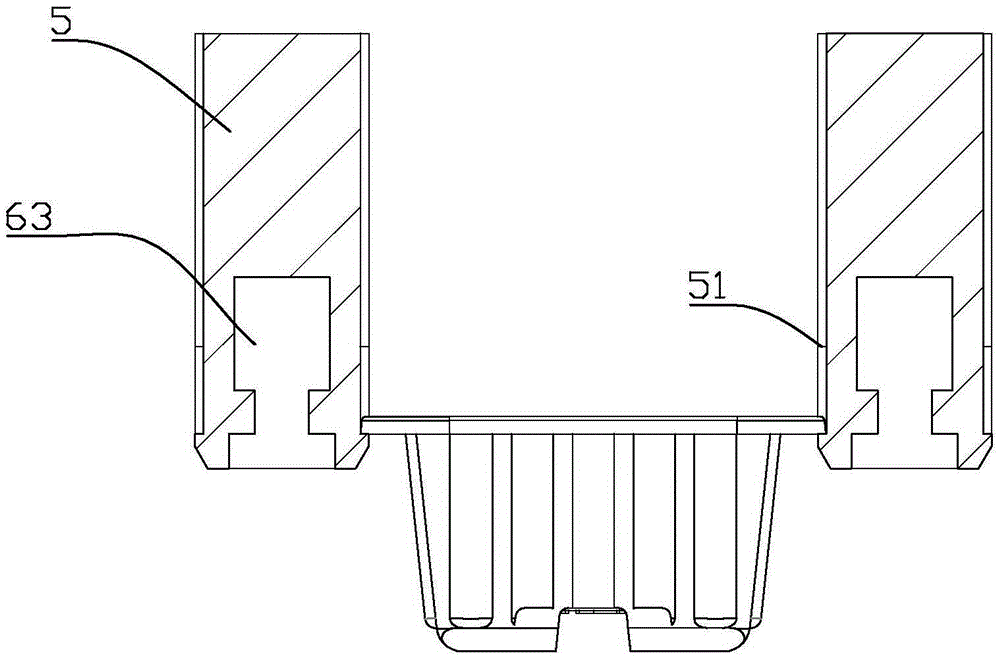

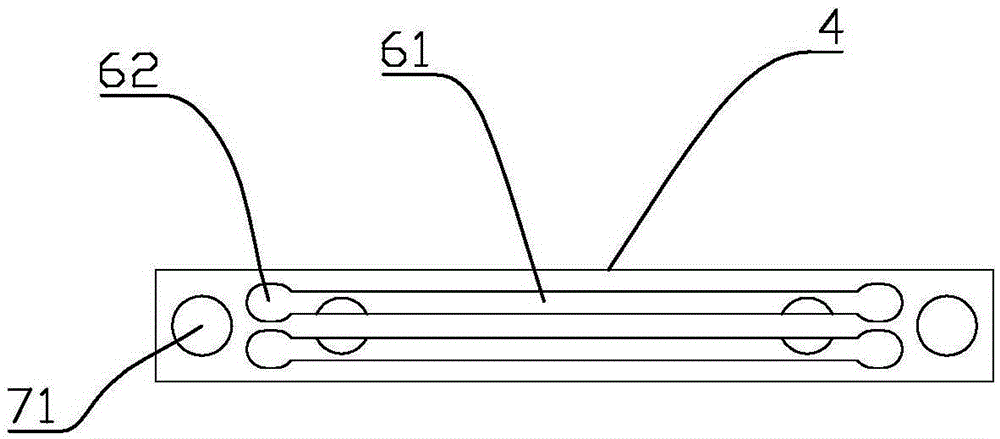

[0018] refer to Figure 1 ~ Figure 4 , the present invention is a finished blanking machine formwork used for forming sheets and plates, including a cylinder fixed plate 1, a plurality of pillars 2, a movable plate 3, two first beams 4 and a number of second beams 5, the pillars 2 One end is connected to the cylinder body fixing plate 1, the other end is connected to the first beam 4, the two ends of each second beam 5 are respectively connected to the two first beams 4, and the distance between adjacent second beams 5 can be adjusted , The movable plate 3 is movably installed on the fixed plate 1 of the cylinder body. The present invention adopting the above-mentioned structure can adjust the distance between the second beams 5 according to the specific structure of the die by setting the first cross beam 4 and the second cross beam 5, so as to adapt to the discharge of the die, so that the present invention can be applied to Different dies. The structure of the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com