Sizing device for wooden door processing

A wooden door and fixing mechanism technology, applied in the direction of wood processing appliances, manufacturing tools, etc., can solve the problems of reducing the quality of wooden doors, waste wood, time-consuming and laborious, etc., and achieve the effects of improving the quality of wooden doors, saving decoration costs, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

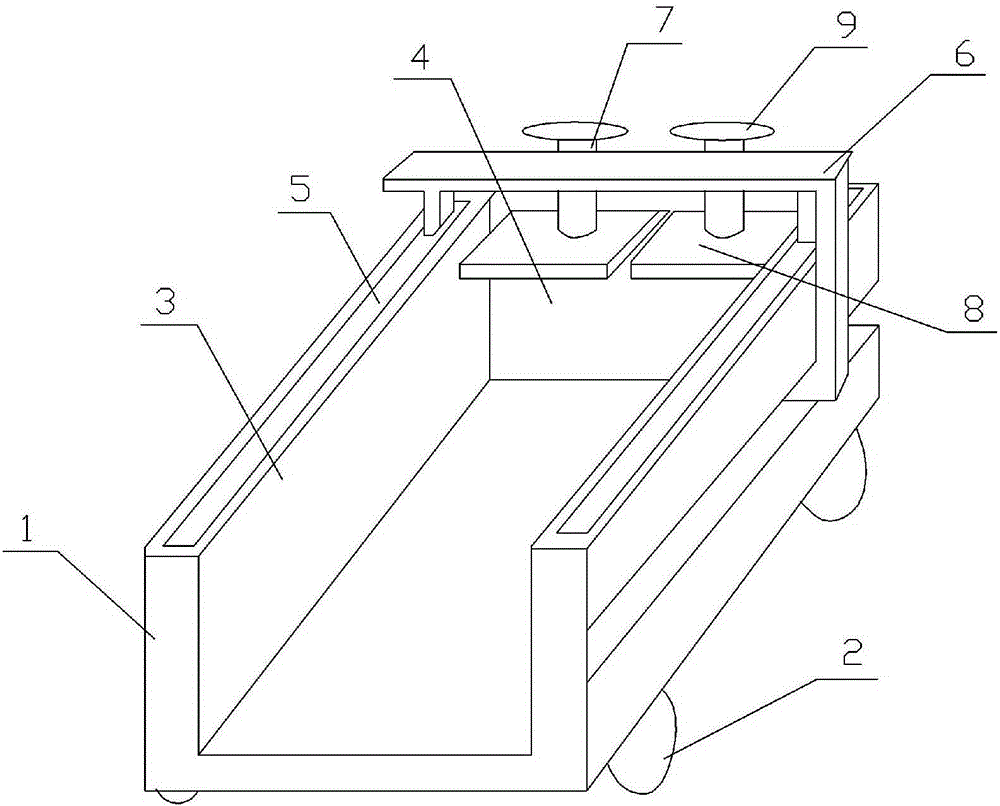

[0011] The reference numerals in the accompanying drawings of the description include: deck 1 , roller 2 , baffle plate 3 , side plate 4 , chute 5 , bracket 6 , screw rod 7 , pressure plate 8 , and turntable 9 .

[0012] The embodiment is basically as attached figure 1 Shown: a shaping device for wooden door processing, including a deck 1 and multiple fixing mechanisms installed on the deck 1, a roller 2 is installed on the bottom of the deck 1, and the deck 1 consists of a baffle plate 3 and two side plates 4 The baffle plate 3 and the side plate 4 form a U-shaped card cavity to accommodate the wooden door. The tops of the two side plates 4 are provided with chute 5. The fixing mechanism includes a bracket 6 and a screw rod 7. Both ends of the bracket 6 are provided with The projection that the chute 5 matches, the screw rod 7 is installed on the bracket 6, the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com