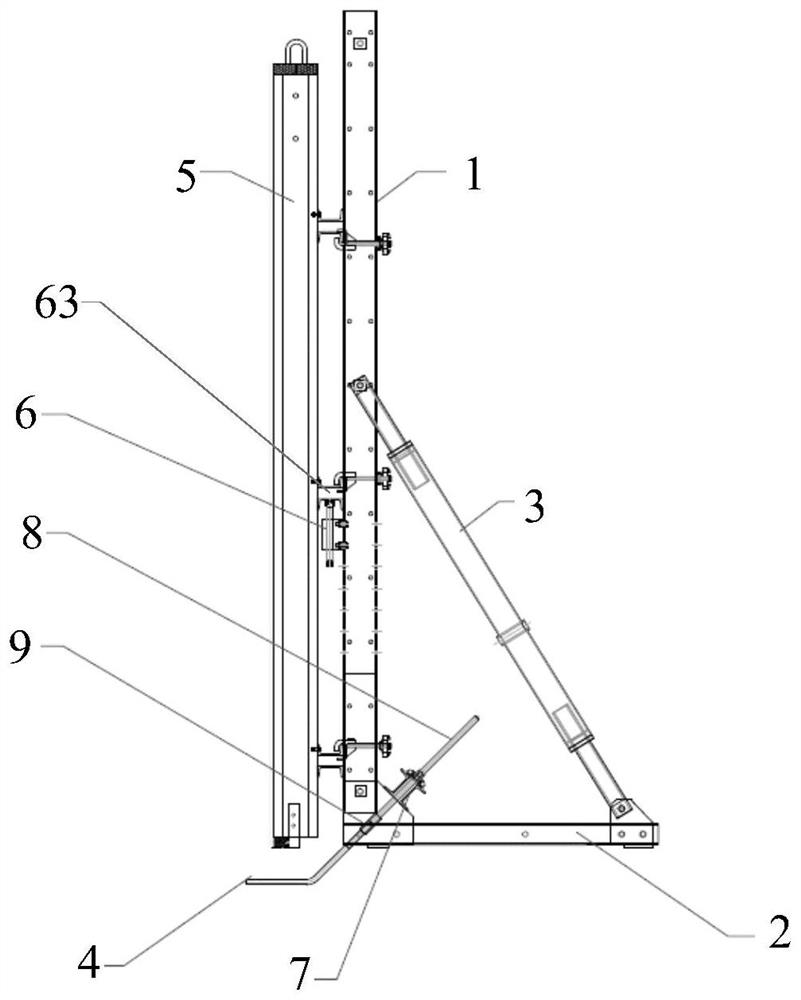

A bracket capable of unilaterally supporting a wall formwork

A wall and formwork technology, applied in formwork/formwork/work frame, formwork/formwork/work frame connectors, reducing greenhouse gases, etc., can solve the problem of inability to support formwork in a conventional way, the existence of safety and quality Hidden dangers, control of concrete side pressure and other issues, to achieve the effect of improving appearance quality, good economic benefits, and avoiding tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

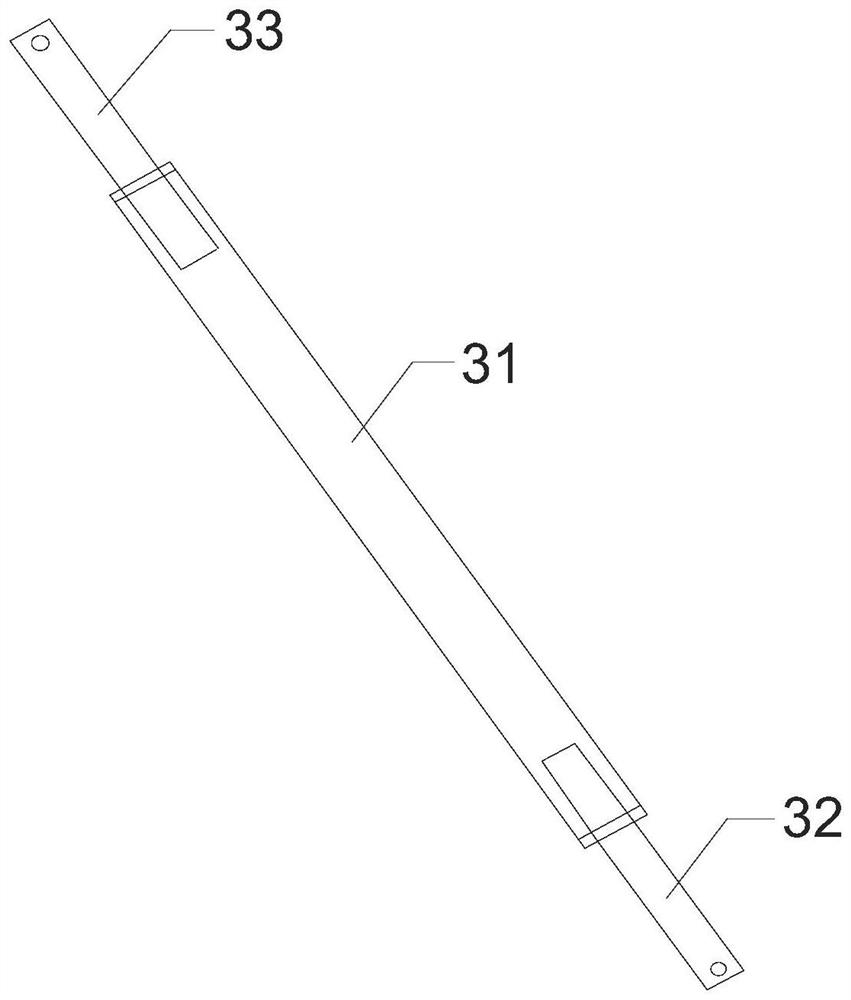

[0036] The first: the telescopic assembly adopts a hydraulic cylinder, an air cylinder or an electric push rod assembly, and the present embodiment adopts a hydraulic cylinder. Scaling group

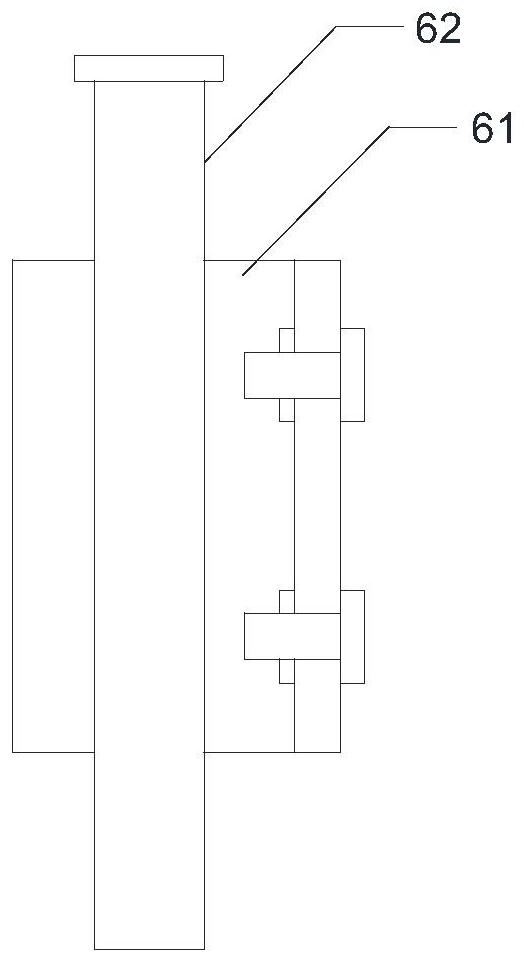

[0038] In addition, also includes a formwork adjuster 6, the formwork adjuster 6 is used to adjust the verticality of the wall forming formwork. Template key

Embodiment 3

do:

(1) before pouring the next floor slab, the anchor bolts must be pre-buried accurately first, and the free ends of the bolts are shaped to the wall.

The distance of the formwork away from the side wall of the bracket side is 350mm, the bolt inclination angle is 45°, and the exposed height and horizontal spacing are well controlled;

(2) after the reinforcement of the wall is bound, the reinforcement of the wall must be temporarily fixed;

(3) clean up the sundries at the root of the wall, level with mortar if necessary;

(4) hoist a plurality of unilateral right-angled triangle supports and template according to the typesetting, and connect adjacent supports with steel pipes

The vertical main back corrugation, after hoisting, the vertical main back corrugation and the wall shaping formwork are firmly connected with fasteners;

[0048] (5) install the pressure beam, the connecting nut and the outer connecting rod, fasten each embedded part anchor screw, and carry out in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com