Sending type sewing machine

A sewing machine and arm type technology, which is applied to sewing machine components, sewing machine casings, sewing machine control devices, etc., can solve problems such as difficulty in adjustment operations, and achieve the effects of easy installation and disassembly operations and improved visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

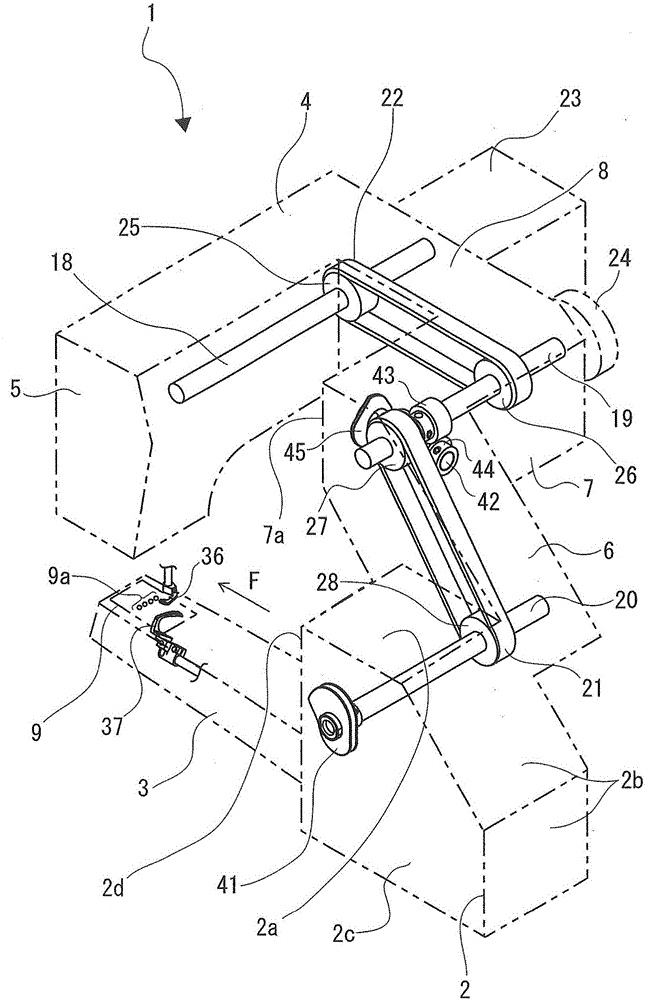

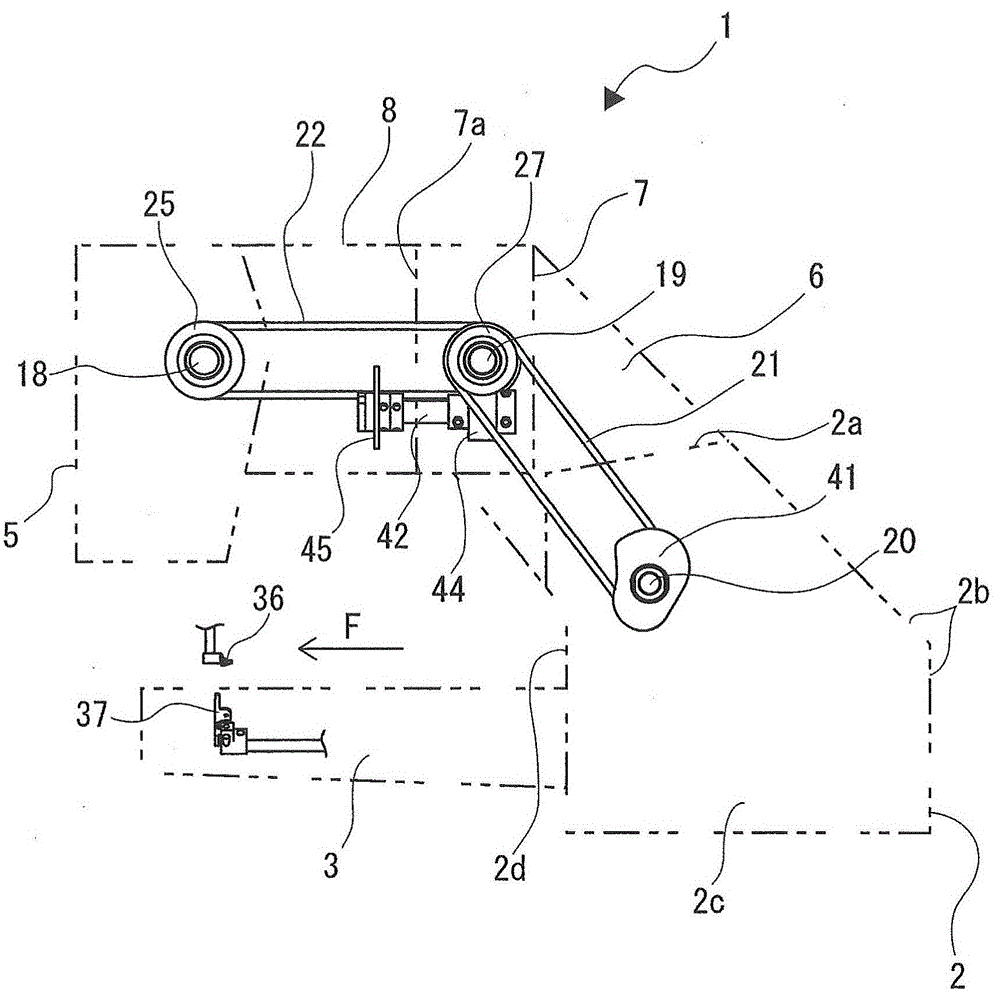

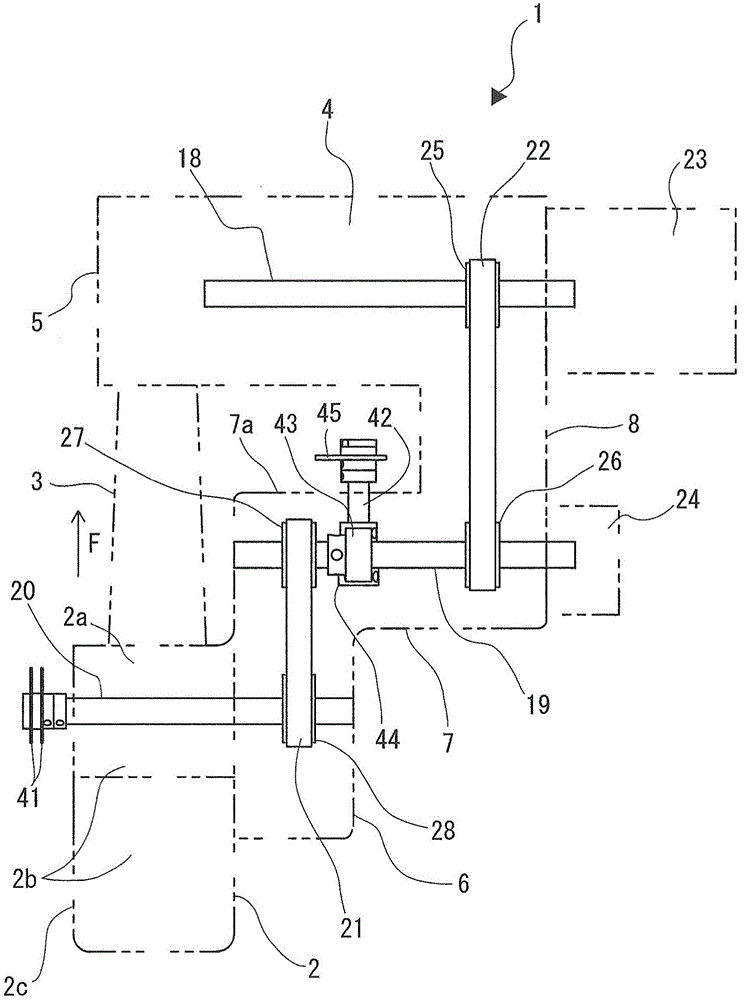

[0059] Hereinafter, a sewing machine main body 1 according to an embodiment of the present invention will be described with reference to the drawings. In addition, the part which forms the housing|casing of the sewing machine main body 1 is shown by the dashed-two dotted line. The base end of the machine barrel 3 is connected to the lower part of the rear surface 2 d of the first machine base 2 , and the front end of the machine barrel 3 extends horizontally toward the cloth feeding direction F. A needle plate 9 is provided on the upper surface of the front end of the barrel 3, and a needle drop position 9a is provided on the needle plate 9. As shown in FIG. Such as figure 2 As shown, the first base 2 is pentagonal when viewed from the left side, and the upper part of the front surface 2b is inclined toward the cloth feeding direction F, that is, rearward, as it goes upward. Moreover, the upper surface 2a of the 1st stand 2 inclines downward toward the cloth feed direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com