Quartering hammer

A technology of breaking hammer and main valve body, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problem of poor control effect of breaking hammer, and achieve the effect of simple structure, convenient use, and prevention of air strike

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

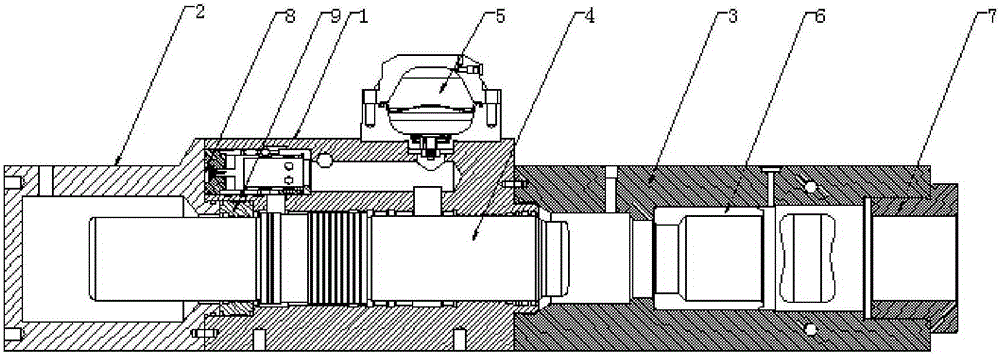

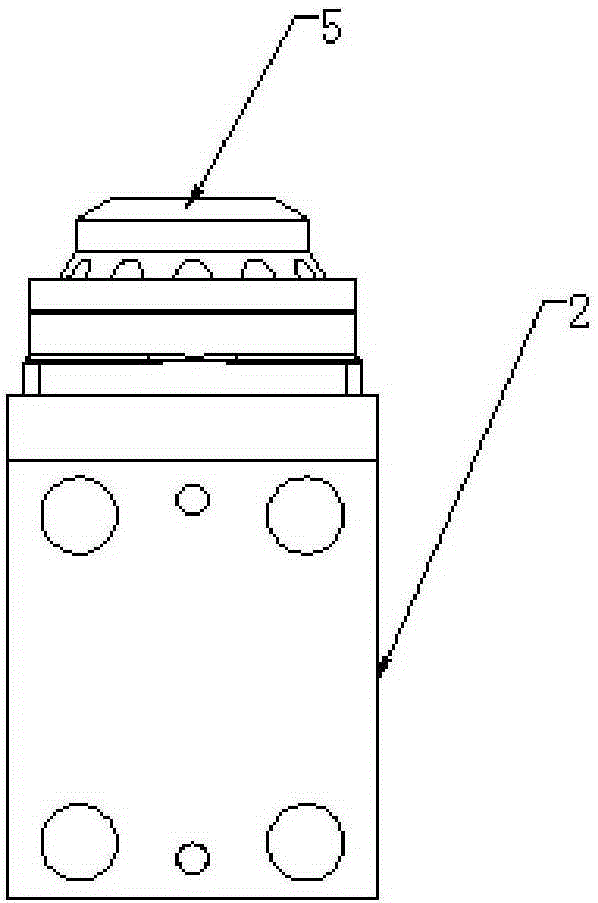

[0015] see figure 1 with figure 2 , a breaking hammer, comprising: an impact main valve body 1, an impact rear seat 2 affixed to the left end of the impact main valve body 1 and an impact front seat 3 affixed to the right end of the impact main valve body 1, the impact main valve body 1 An impact shaft 4 is fitted inside and a buffer nitrogen bottle 5 is fixedly connected to its upper end, and a liner 6 is fitted inside the shock front seat 3 and a guide sleeve 7 is fitted at its free end.

[0016] In the above technical solution, the impact main valve body is the main executive component of the present invention, and is used to drive the impact shaft to perform actions. In addition, in order to ensure the accuracy of the control of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com