Water-cooled canned pump

A canned pump, water-cooled technology, applied in the direction of non-variable-capacity pumps, pumps, pump control, etc., can solve the problems of difficult installation and disassembly of canned pumps, difficulty in processing and manufacturing of canned pumps, and reduced service life, etc., to achieve installation and disassembly. Convenient and flexible, increase strength, prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

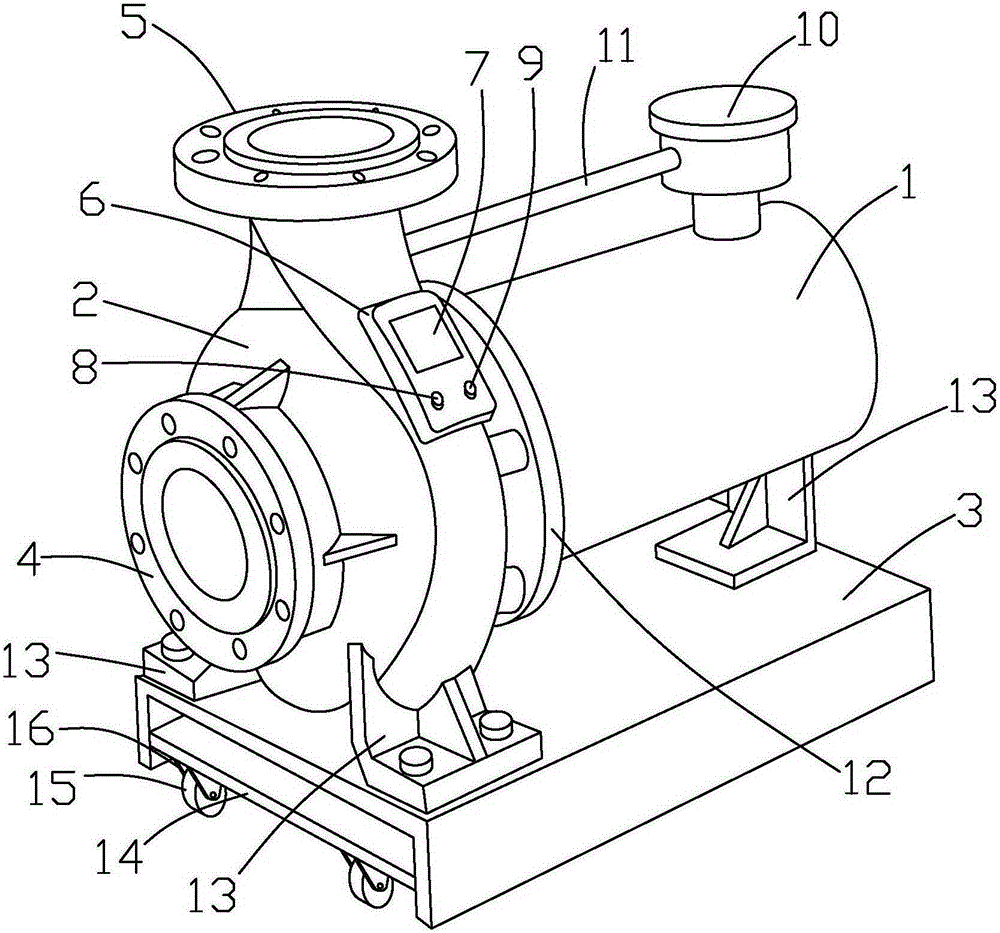

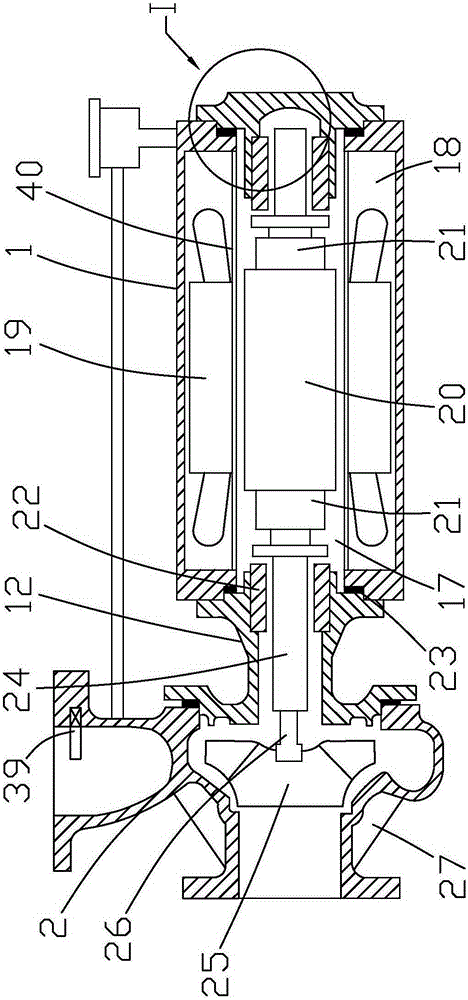

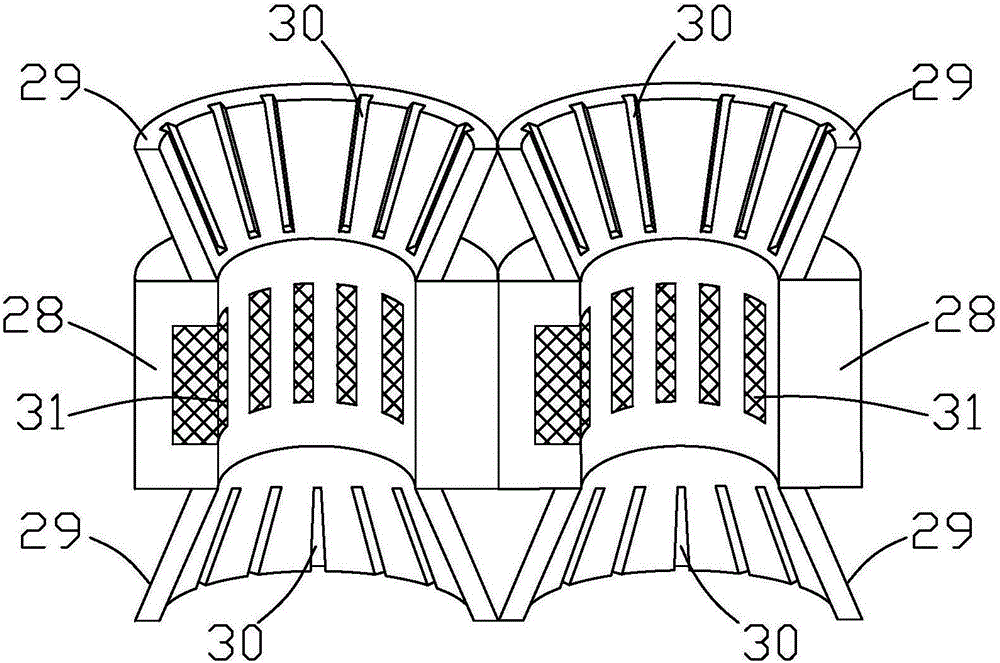

[0029] Such as Figure 1 to Figure 5 As shown, it is a water-cooled canned pump of the present invention. The canned pump includes a casing 1 and a pump body 2. One end of the casing 1 is fixedly connected to the pump body 2 through a positioning connector 12, and the other end of the casing 1 is provided with an end cover. 36. The first sealing ring 23 and the second sealing ring 38 are respectively arranged between the housing 1 and the positioning connector 12 and the end cover 36. The first sealing ring 23 and the second sealing ring 38 can effectively prevent the housing 1 from Leakage occurs at the connection part, which improves the safety of the canned pump. The inside of the casing 1 is provided with a stator 19 and the rotor, and the bottom of the pump body 2 and casing 1 is provided with a base 3. The pump body 2 and casing 1 pass through the support frame. 13 is fixedly connected to the top surface of the base 3, the pump body 2 is provided with a liquid inlet flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com