Fast connection mechanism

A technology of quick connection and connection end, which is applied in the direction of mechanical equipment, couplings, etc., can solve the problems of not tight clamping of the connection pipe, non-adjustable parts, non-replaceable parts, etc., to achieve enhanced firmness and stability, replacement and maintenance costs Low cost and high product assembly yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

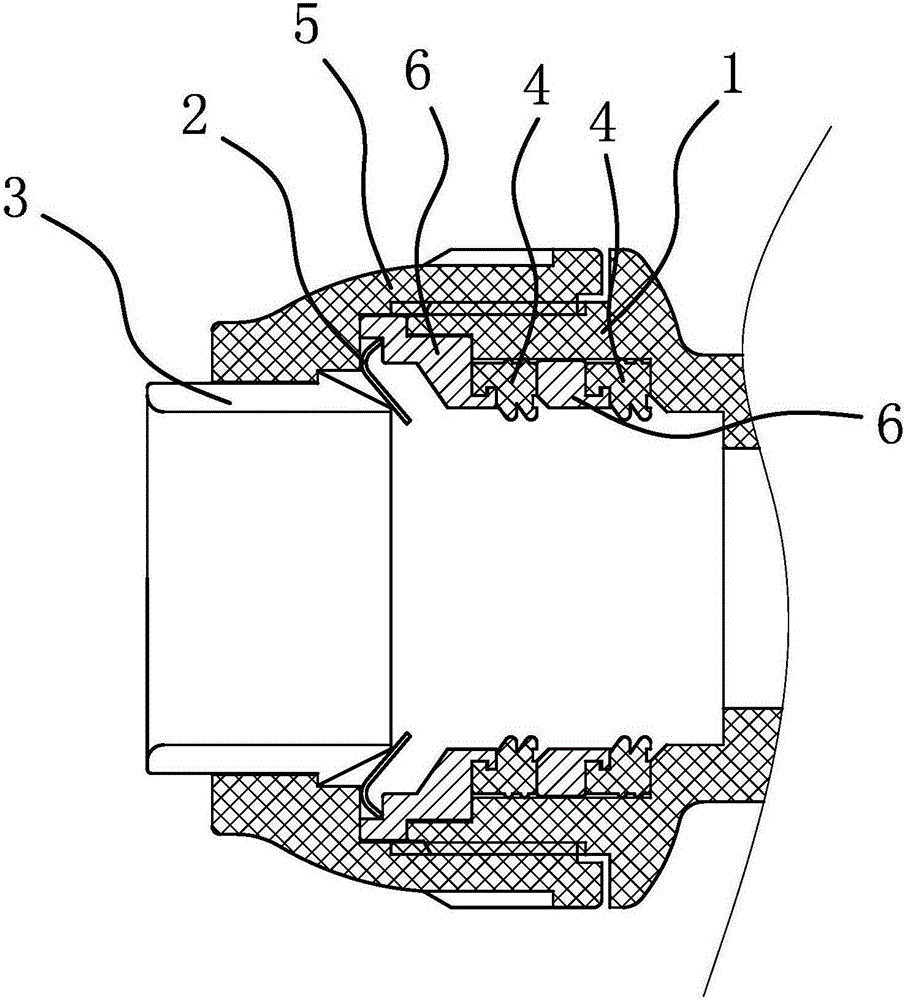

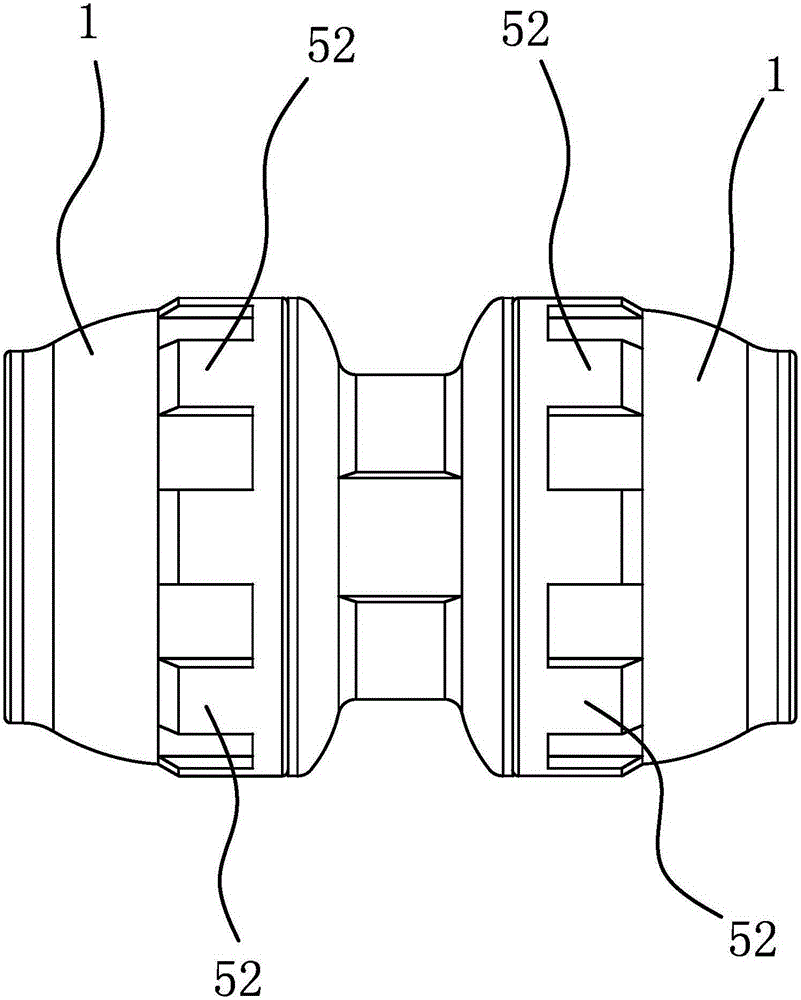

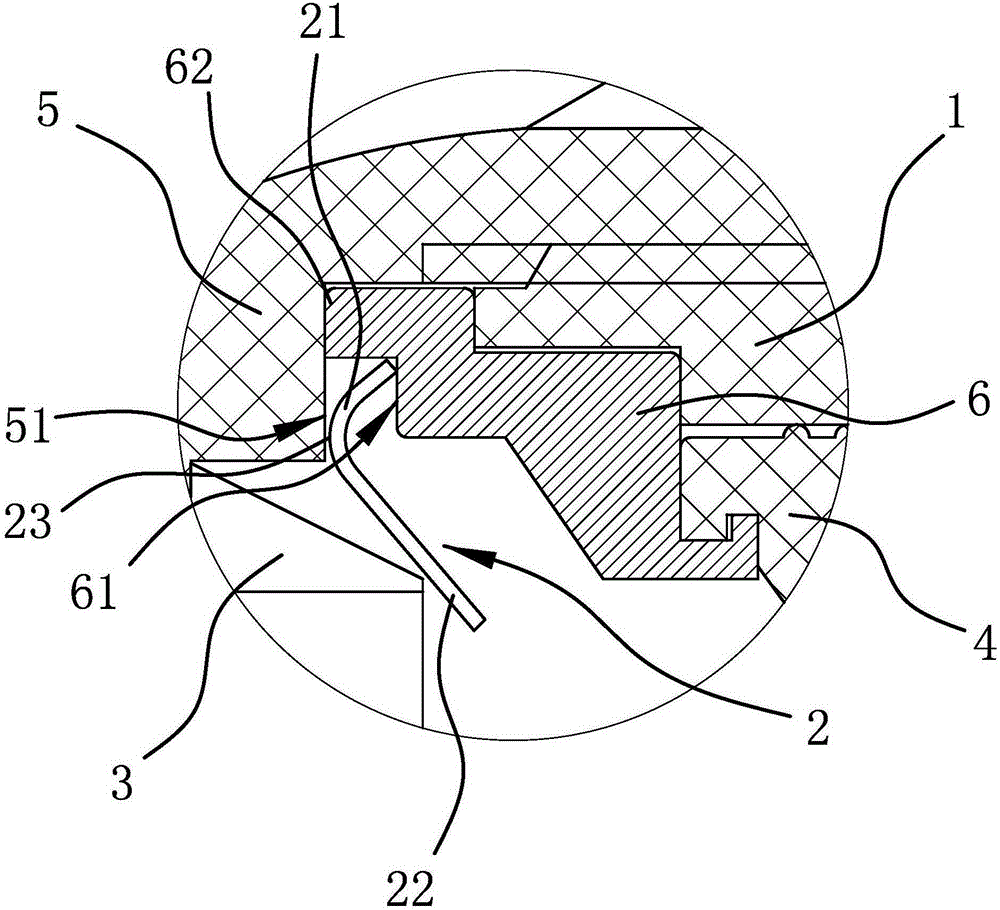

[0030] Such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the quick connection mechanism is set at the cylindrical connecting end 1 on the shell, including a snap ring 2, a cylindrical intubation tube 3 and a ring-shaped seal set on the inner wall of the connecting end 1. Circle 4. Wherein, the snap ring 2 includes a ring-shaped collar portion 21 and a plurality of locking teeth portions 22 evenly distributed on the inner edge of the collar portion 21 , and the locking teeth portions 22 and the collar portion 21 are connected as a whole. The locking tooth part 22 is arranged obliquely in a direction away from the port of the connecting end 1, that is, the outer end of the locking tooth part 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com