Energy-saving furnace

An energy-saving furnace and furnace body technology, which can be used in household furnaces/stoves, lighting and heating equipment, sustainable buildings, etc., and can solve problems such as insufficient combustion, waste of energy, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

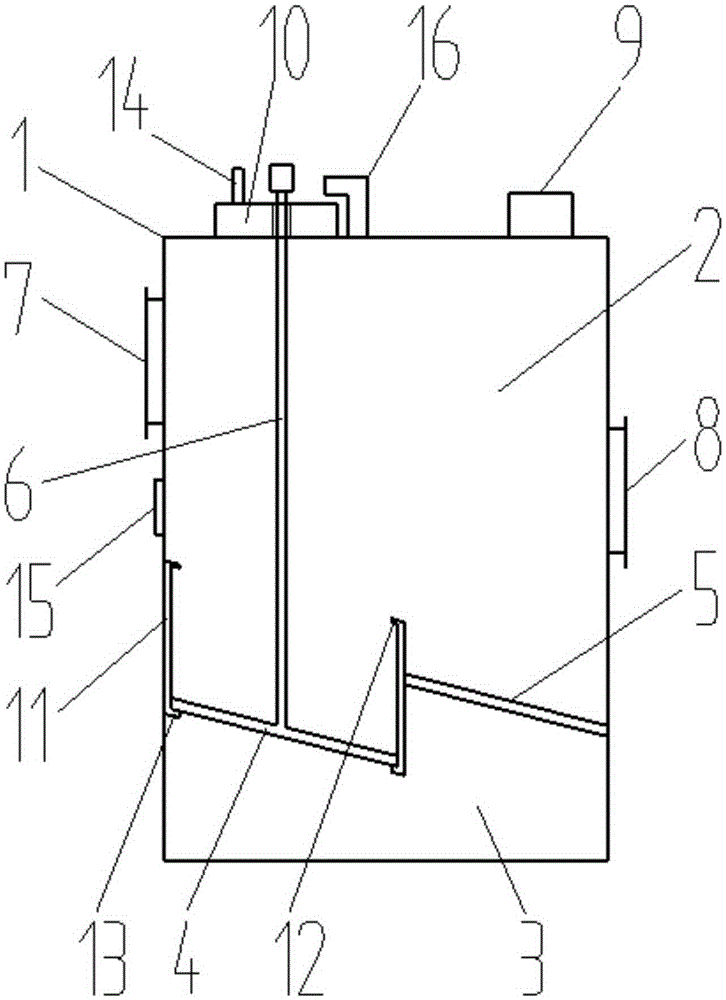

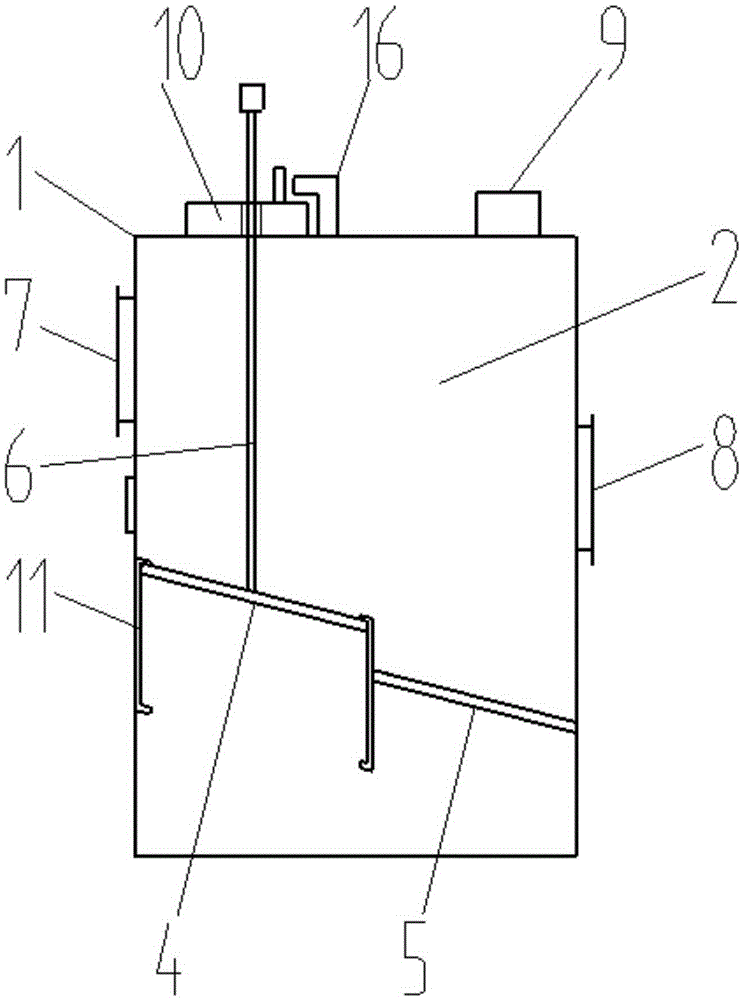

[0023] The energy-saving furnace provided by the present invention, such as figure 1 As shown, including the furnace body 1, the furnace body 1 is provided with a fire grate, and the fire grate divides the furnace into a combustion chamber 2 and ash chamber 3, the combustion chamber 2 is located above the fire grate, and the furnace ash chamber 3 is located below the fire grate, and the combustion chamber 3 is located below the fire grate. Coal cannot be fully burned, and unburned carbon particles are produced during the combustion process. The unburned carbon particles are mixed with carbon monoxide, polycyclic aromatic hydrocarbons, aldehydes and other pollutants to form the so-called ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com