Thermal power generating unit air volume and air pressure decoupled control method

A thermal power unit, decoupling control technology, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problem of inaccurate local measurement units, etc., to improve the overall control performance and control effect , to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0037] The air volume and air pressure decoupling control method of the thermal power unit in the present invention is mainly realized in the following ways:

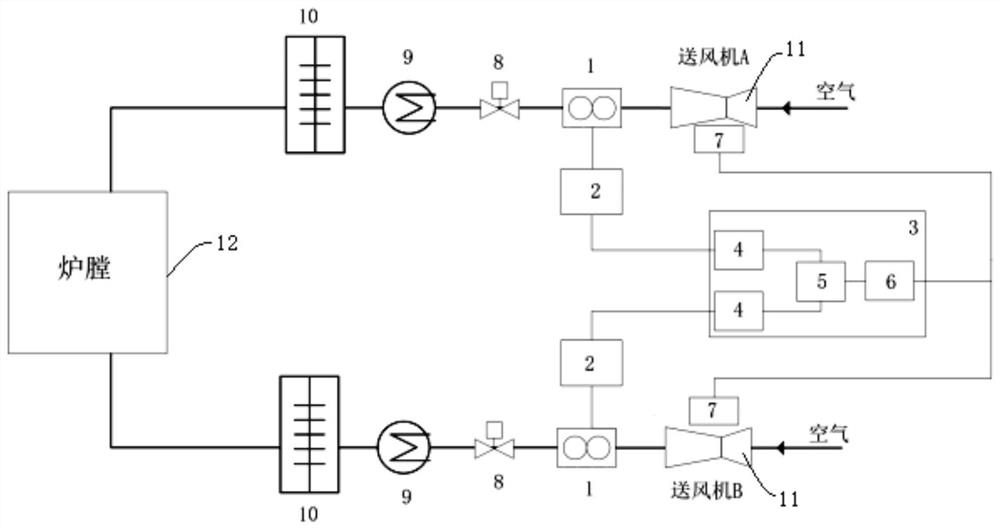

[0038] 1) The primary air volume is decoupled from the total air volume control, and the air volume at the outlet of the blower is taken as the total secondary air volume. The multi-point matrix air volume measurement device is used to measure and adjust the air volume at the outlet of the blower in real time and accurately, so as to realize the control of the total secondary air volume. The accurate measurement of the total secondary air volume is used as the total air volume input in the boiler combustion control;

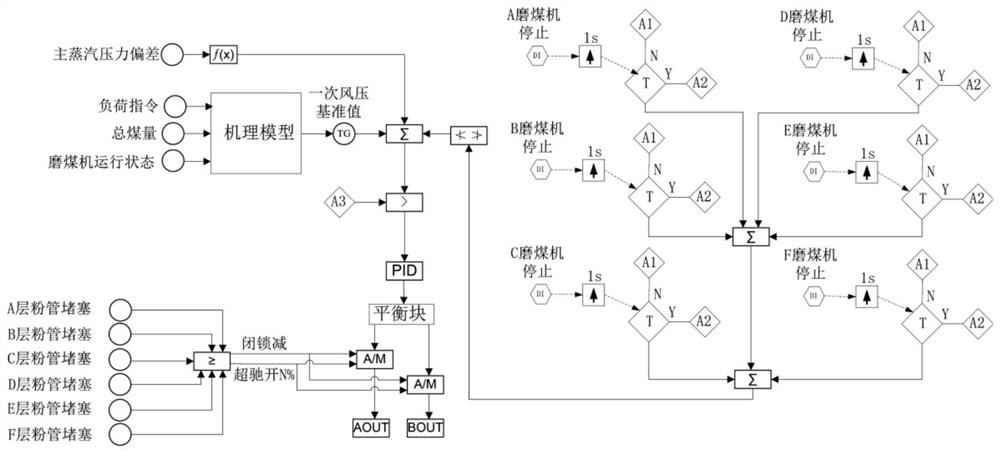

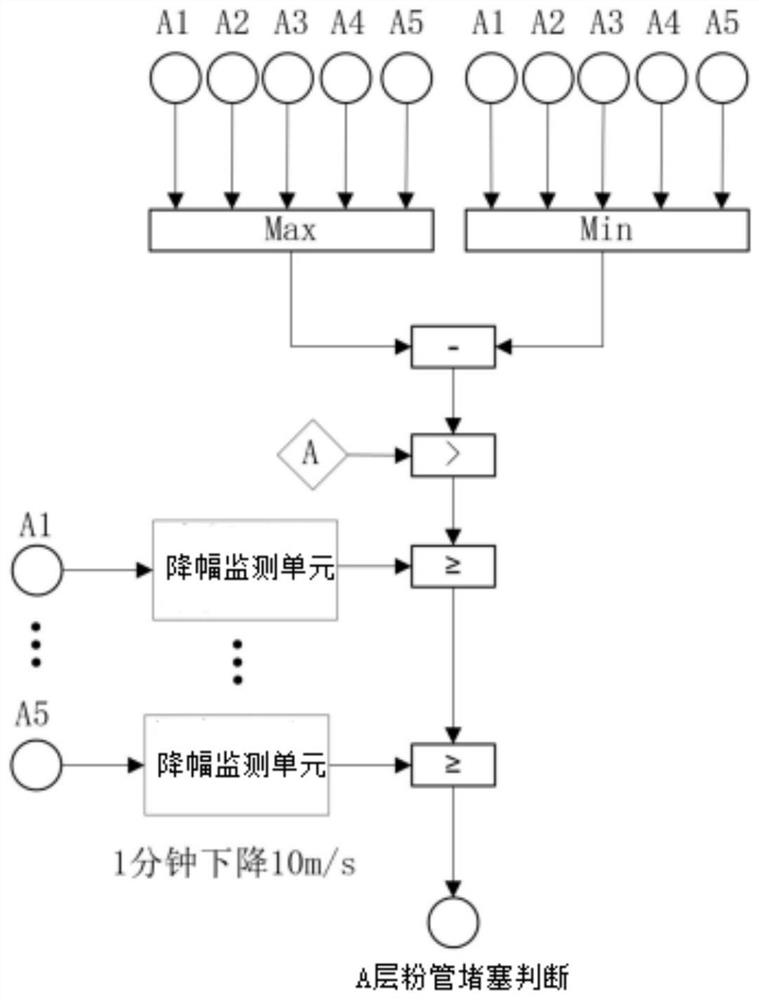

[0039] 2) Taking the air pressure of the primary main pipe as the target value of the primary air control, by optimizing the control logic of the primary air pressure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com