Biomass boiler feeding device and using method thereof

A technology of biomass boiler and feeding device, which is applied in the direction of combustion method, supply configuration, fuel supply, etc., which can solve the problems of prolonged fuel start-up time, aggravated pollutant emissions, and decreased combustion efficiency, so as to improve efficiency and reduce emissions , the effect of avoiding the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

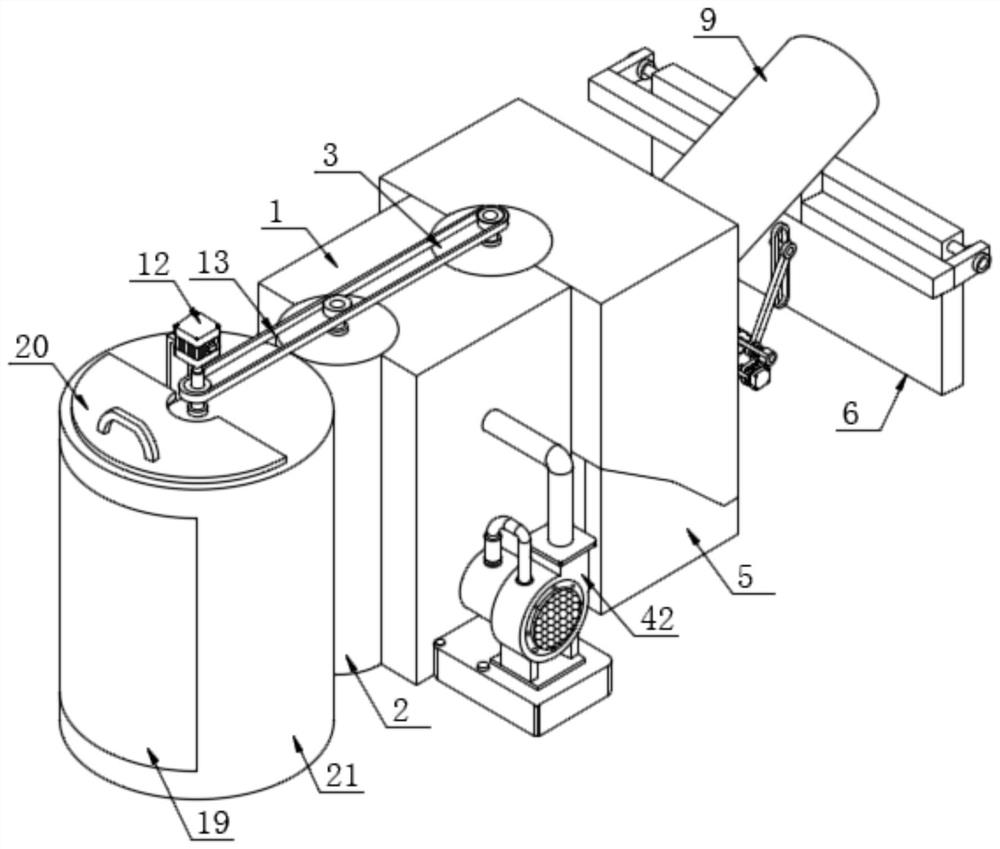

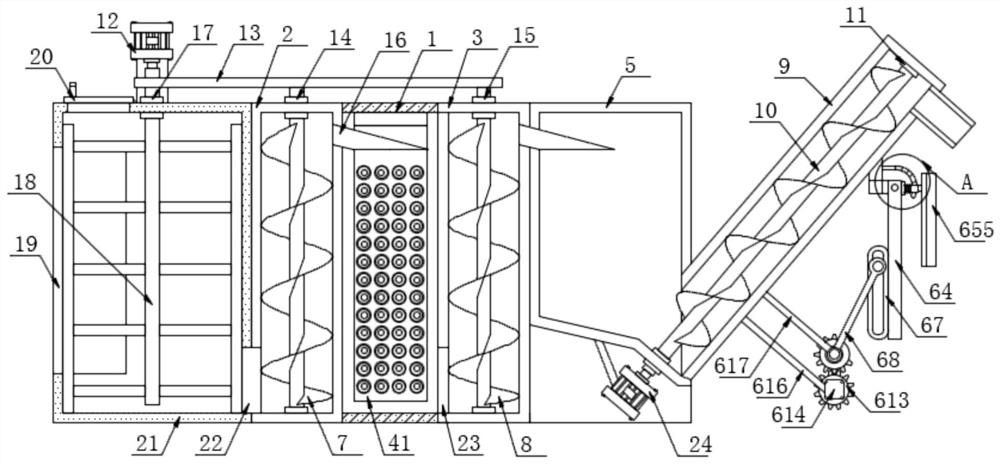

[0032] according to figure 1 , figure 2 , Image 6 with Figure 7 As shown, the present invention provides a biomass boiler feeding device, which includes a box body 5, the right side of the box body 5 is clamped with a feeding cylinder 9, and the side of the feeding cylinder 9 is fixedly connected with a feeding mechanism 6, A third screw shaft 10 is arranged in the upper material barrel 9. By setting the third screw shaft 10, the third screw shaft 10 can carry out the work of conveying and loading fuel. One end of the third screw shaft 10 is connected to the third motor 24. The output shaft is fixedly connected, the side of the third motor 24 is fixedly connected with the lower surface of the box body 5, the lower surface of the box body 5 and the upper material cylinder 9 are clamped with the third bearing 11, by setting the third bearing 11, so that The third bearing 11 can ensure the stable rotation of the third screw shaft 10. The two third bearings 11 are all sleeve...

Embodiment 2

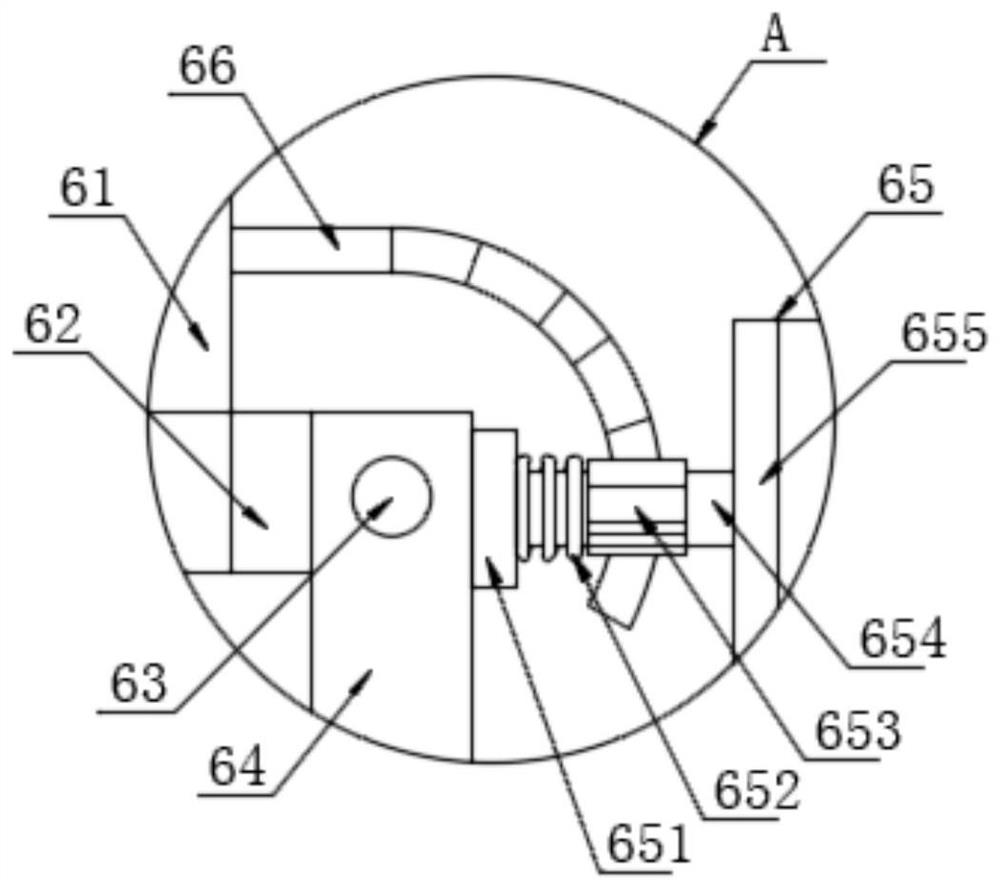

[0035] On the basis of Embodiment 1, such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the feeding mechanism 6 includes a support plate 61, the upper surface of the support plate 61 is fixedly connected to the side of the feeding cylinder 9, and the right side of the support plate 61 is fixedly connected with two fixed blocks 62, and the two fixed blocks 62 are fixedly connected to each other. The pin shaft 63 is hinged with the extension plate 64, and by setting the pin shaft 63, the pin shaft 63 can provide a movable point for the extension plate 64, and can support the extension plate 64 at the same time, so as to ensure that the extension plate 64 can normally perform angular activities, extend On the right side of the plate 64, the swing assembly 65 is engaged with the gear rod 66, and one end of the gear rod 66 is fixedly connected to the side of the upper material cylinder 9, and the left side of the extension plate 64 is fixedly connected to the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com