Silicon carbide environmentally-friendly smelting process and device thereof

A smelting method and technology of silicon carbide, applied in the field of silicon carbide smelting process of environmental protection, can solve the problem of smelting method of silicon carbide polluting the earth and sky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

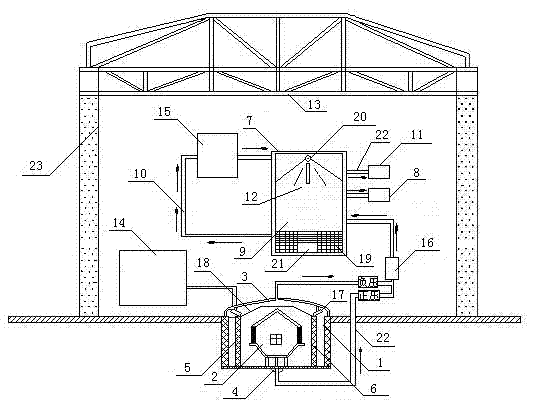

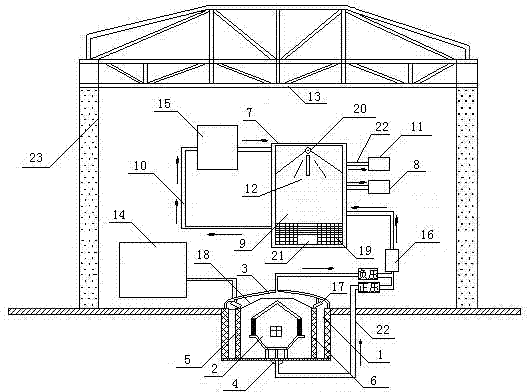

[0038] The environmental-friendly smelting method of silicon carbide of the present invention adopts underground smelting, the production method of dust purification utilization on the ground and computer monitoring system control on the ground. The underground smelting workshop 1 with a width of 40 meters and a depth of 8 meters adopts the traditional silicon carbide smelting method for smelting; b. The hot fume purification step collects smelting hot fumes through the hot fume collection shutter 3 and the hot fume collector 4 at the bottom of the silicon carbide kiln And sent to the dust purification and distribution chamber 7 on the ground for purification and distribution; c, the computer monitoring step collects the smelting state in the closed silicon carbide kiln 2 through the camera 17 inside the hot smoke collection shutter 3 and sends it to the computer monitoring room 14 on the ground for monitoring .

[0039] A device for realizing the underground smelting method o...

Embodiment 2

[0048] The silicon carbide environmental-friendly smelting method of the present invention adopts underground smelting, the production method of dust purification utilization on the ground and computer monitoring system control on the ground. The underground smelting workshop 1 with a width of 50 meters and a depth of 10 meters adopts the traditional silicon carbide smelting method for smelting; b. The hot fume purification step collects the smelting hot fume through the hot fume collection shutter 3 and the hot fume collector 4 at the bottom of the silicon carbide kiln And sent to the dust purification and distribution chamber 7 on the ground for purification and distribution; c, the computer monitoring step collects the smelting state in the closed silicon carbide kiln 2 through the camera 17 inside the hot smoke collection shutter 3 and sends it to the computer monitoring room 14 on the ground for monitoring .

[0049]A device for realizing the underground silicon carbide s...

Embodiment 3

[0058] The environmental-friendly smelting method of silicon carbide of the present invention adopts underground smelting, the production method of dust purification utilization on the ground and computer monitoring system control on the ground. The underground smelting workshop 1 with a width of 60 meters and a depth of 12 meters adopts the traditional silicon carbide smelting method for smelting; b. The hot fume purification step collects smelting hot fumes through the hot fume collection louver 3 and the hot fume collector 4 at the bottom of the silicon carbide kiln And sent to the dust purification and distribution chamber 7 on the ground for purification and distribution; c, the computer monitoring step collects the smelting state in the closed silicon carbide kiln 2 through the camera 17 inside the hot smoke collection shutter 3 and sends it to the computer monitoring room 14 on the ground for monitoring .

[0059] A device for realizing the underground smelting method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com