Novel drying device for fluidized bed

A new type of fluidized bed drying technology, applied in the direction of drying gas arrangement, drying solid materials, heating to dry solid materials, etc., can solve the problems of increased difficulty in starting the fluidized bed, insufficient drying of materials, and insufficient drying of materials, etc. Achieve the effect of improving drying effect, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

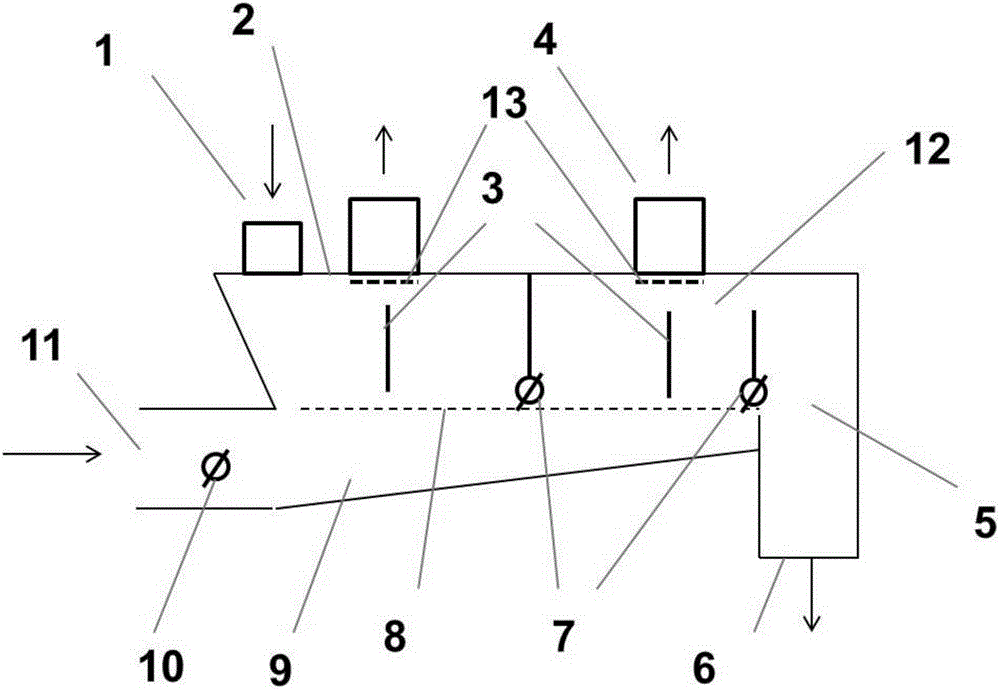

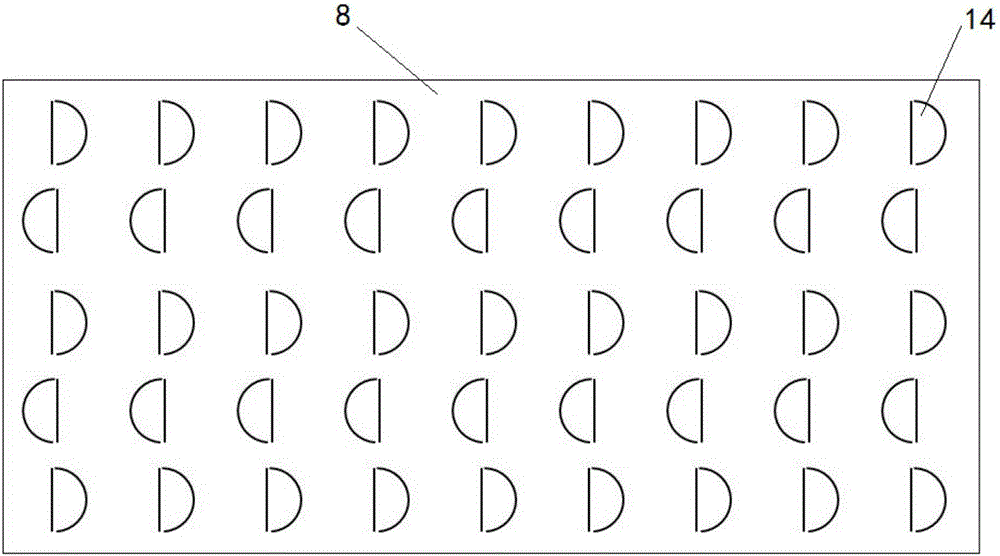

[0036] Embodiment: a kind of novel fluidized bed drying device, its structure can refer to figure 1 Shown: including the box body 2, there are multiple air distribution plates 8 that are airtightly connected horizontally inside the box body 2, the air inlet channel 9 is between the air distribution plate 8 and the bottom of the box body 2, the air distribution plate 8 and the box body 2 is a drying chamber 12 between the tops.

[0037] One end of the air inlet channel 9 protrudes from the box body 2 and is a feed inlet 11 , and a pulse valve 10 is installed on the feed inlet 11 to realize pulsed air supply to the drying chamber 12 .

[0038] In the above-mentioned box body 2, a feed inlet 1 is provided at the left end of the top, and an air outlet 4 is respectively provided at the central position and the right position of the top, and both the feed inlet 1 and the air outlet 4 communicate with the drying chamber 12, The right side of the box body 2 is the collecting channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com