Transformer station overhaul trolley

A technology for substations and trolleys, applied to trolleys, motor vehicles, electrical components, etc., can solve the problems of reducing the utilization rate of the switch room site and unfavorable standardization management of substations, and achieve the effects of simple and reliable design, reduced quantity, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

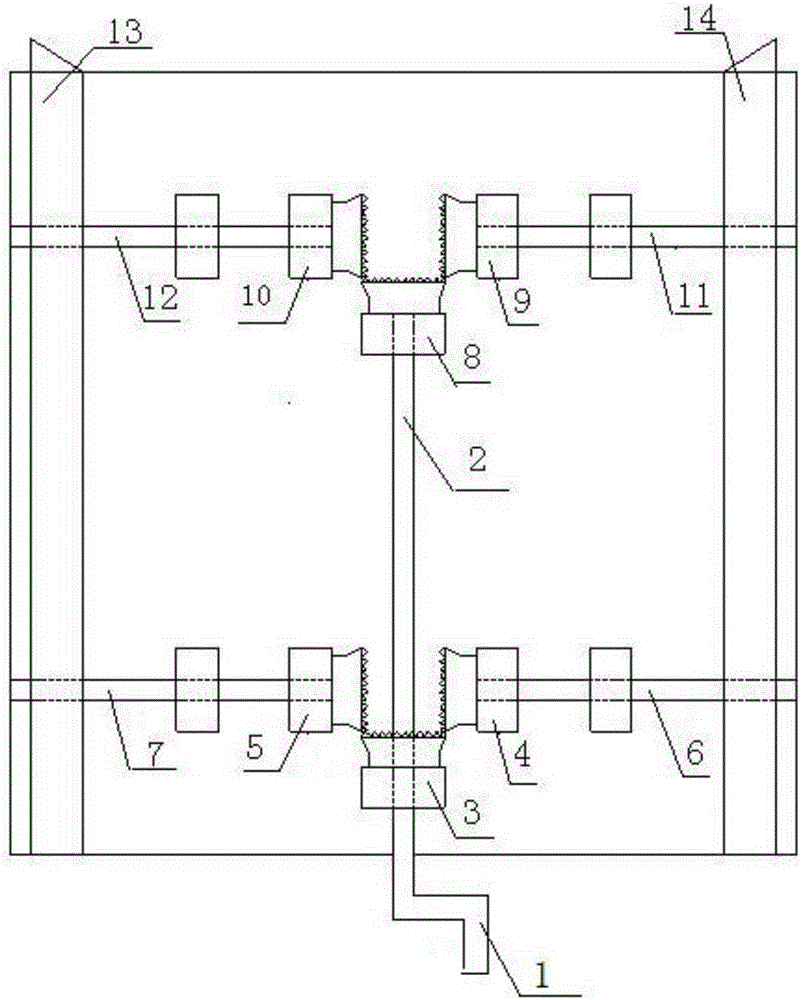

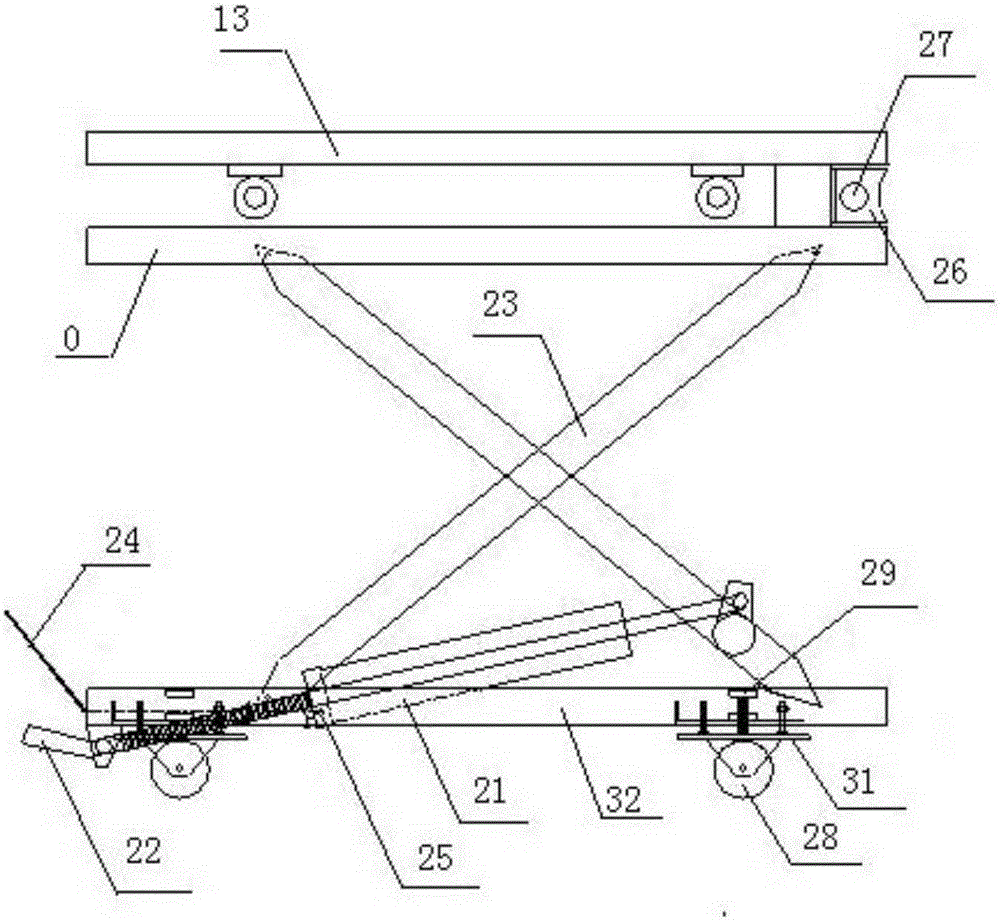

[0023] Such as figure 1 As shown, the substation maintenance trolley includes a working platform 0, a handle 1, a first connecting rod 2, a first gear 3, a second gear 4, a third gear 5, a second connecting rod 6, a third connecting rod 7, a fourth Gear 8, fifth gear 9, sixth gear 10, fourth connecting rod 11, fifth connecting rod 12, left rail member 13, right rail member 14; the first gear 3, second gear 4, the first gear The third gear 5, the fourth gear 8, the fifth gear 9, and the sixth gear 10 are bevel gears; the second connecting rod 6 and the third connecting rod 7 are arranged on the table top of the working platform 0 in a straight line at intervals, so The adjacent ends of the second connecting rod 6 and the third connecting rod 7 are provided with the second gear 4 and the third gear 5 respectively; On the table top of the platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com