A kind of embedded installation method of functional module on plant fiber mattress

A plant fiber, functional module technology, applied in mattresses, spring mattresses, filled mattresses, etc., can solve the problems of easy loosening of screws and rivets, low surface density of mattresses, and human health effects, and achieves the effect of not easy to fall off, Good fixed effect, improve the effect of fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

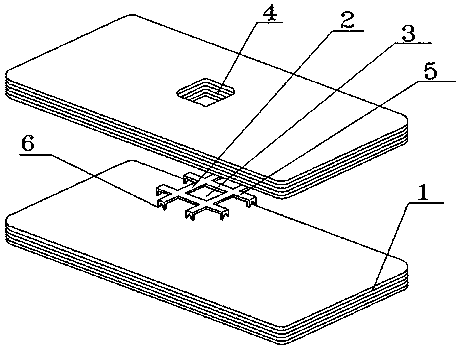

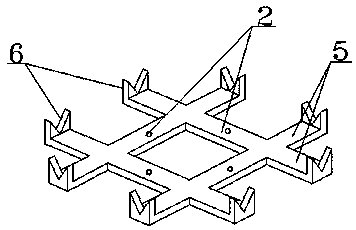

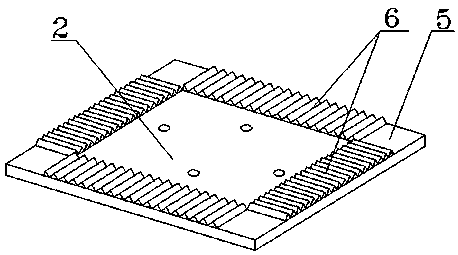

[0017] Embodiment: a kind of built-in installation method of the functional module on the plant fiber mattress, the steps are as follows: as attached figure 1 As shown, the plant fiber monolithic layer 1 is first made, and more than 2 layers of the plant fiber monolithic layer 1 are stacked. According to the design requirements, when stacked to a certain thickness, the stacked plant fiber monolithic layer 1 Put it into the mounting frame 3, and then stack the plant fiber monolithic layer 1 on the plant fiber monolithic layer 1 where the mounting frame 3 is placed according to the design until the thickness required by the design is reached. Then heat-press and vulcanize the plant fiber monolithic layer 1 that has reached the thickness to obtain a plant fiber elastic material; finally set a groove 4 above the installation frame 3 in the plant fiber elastic material, and place the functional module in the groove 4 Install it in the middle, so that the functional module is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com