Self-cleaning filter for drop irrigation water

A technology for cleaning filters and water filters, applied in fixed filter element filters, filter circuits, filter separation and other directions, it can solve the problems of poor filtering effect, inconvenient filtering and cleaning, clogging of drip irrigation pipes, etc., so as to achieve convenient use and maintenance. , convenient operation, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

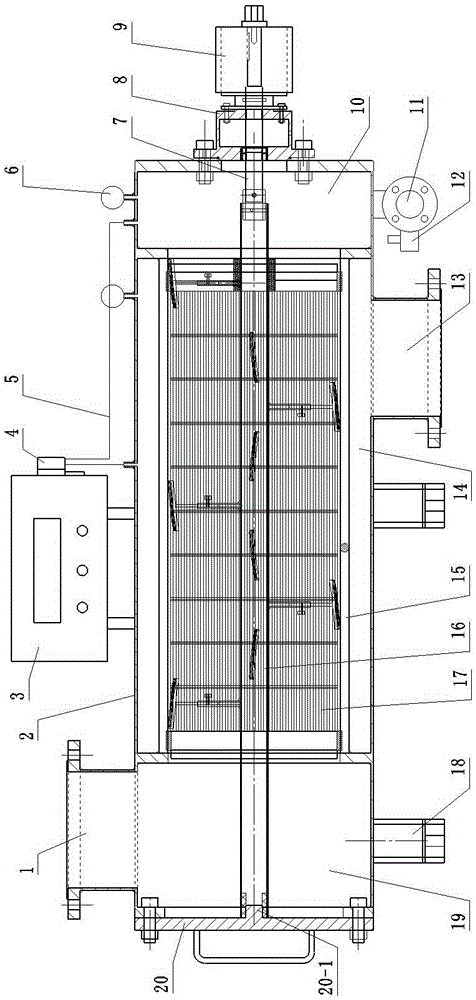

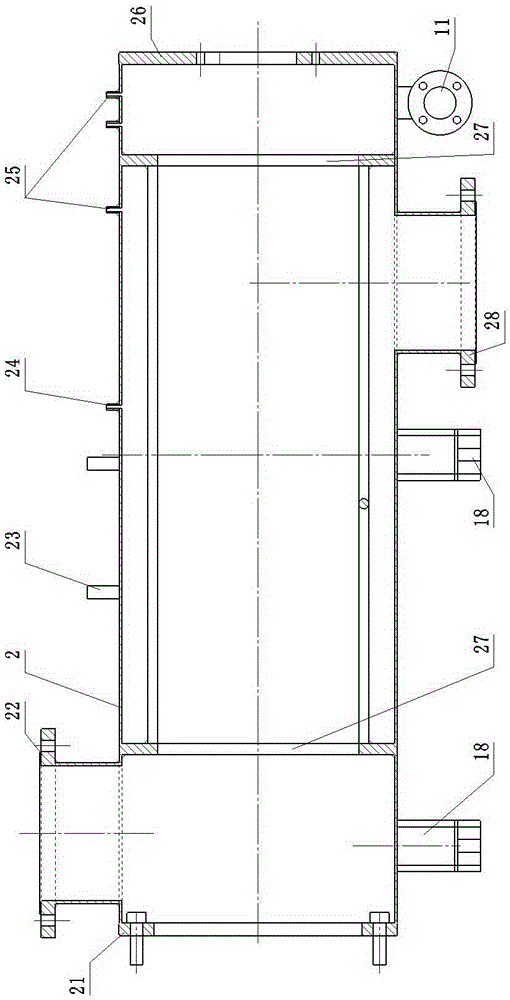

[0036] refer to figure 1 — Figure 9 , a self-cleaning filter for drip irrigation in the present invention, comprising a tank body 2, which is provided with a water inlet 1, a water outlet 13, and a sewage outlet 11, and one end of the tank body 2 is provided with an end cover 20, and the other side A sealing cover 8 is provided, a cylindrical filter screen 17 is arranged axially in the tank body 2, a cleaner 16 is arranged in the filter screen 17, a controller 3 and a cleaning motor 9 are arranged outside the tank body 2; the controller 3 is Box-type liquid crystal display multi-axis controller, the starting mode is partial pressure difference self-cleaning start. The tank body 2 is horizontal and horizontal, the water inlet 1 is located above the tank body 2 , the water outlet 13 is located below the tank body 2 , and the tank body 2 is provided with a support 18 .

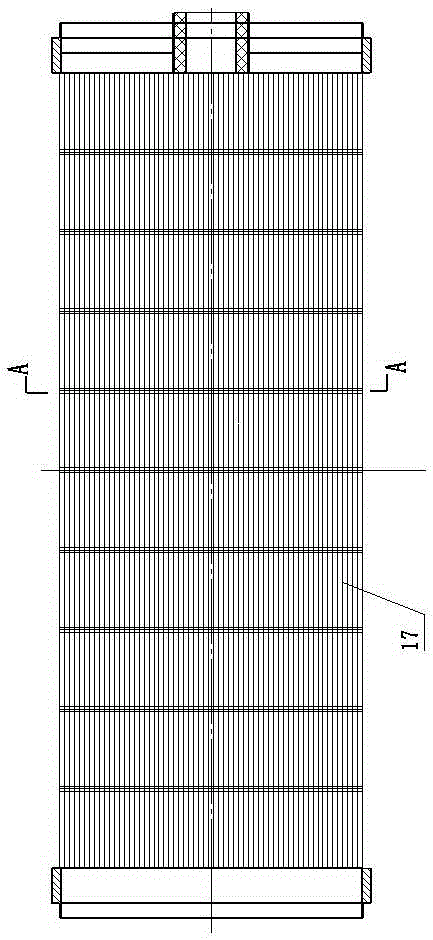

[0037]The filter screen 17 is fixed in the tank body 2 by the filter screen support 15 and the filter scree...

Embodiment 2

[0044] Compared with Embodiment 1, the difference lies in that the cleaning brushes 32 are arranged around the central rotating shaft 33 in a helical manner.

Embodiment 3

[0046] Compared with Embodiment 1, the difference lies in that the filter screen 17 is a steel wire mesh, and the cross section of the steel wire 29 used is wedge-shaped. When the steel wire 29 is installed, the wedge-shaped big end 30 faces inward and the small end 31 faces outward.

[0047] Example 3:

[0048] Compared with Embodiment 1, the difference lies in that the controller 3 is a box-type liquid crystal display multi-axis controller, and the starting mode is self-cleaning start-up with fixed time or manual cleaning start-up mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com