Paint mixer feed system

A feeding system and mixer technology, applied in mixer accessories, mixers, dissolving and other directions, can solve the problems of increasing labor intensity, not meeting the requirements of scientific and technological modernization, and unable to achieve accurate feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

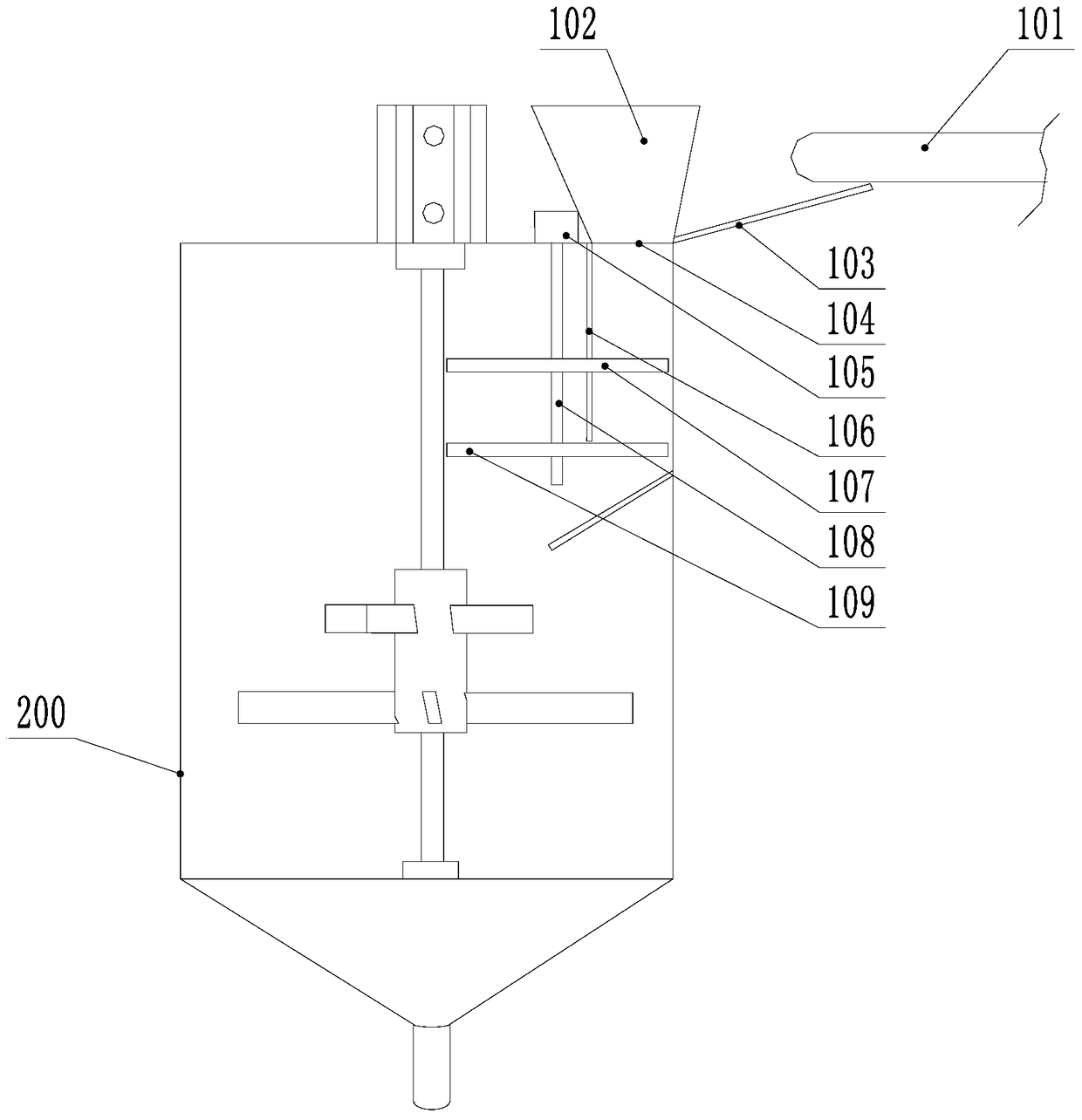

[0039] The existing mixers have very rough control of the feeding speed and cannot achieve the effect of precise feeding, and can only be added quantitatively by manual labor, which increases the labor intensity and does not meet the requirements of technological modernization. In addition, vertical mixers are often used in the chemical industry. Many mixers have a high level. The workbench is set up as two stairs, or a series of temporary climbing ladders are set outside the box. Workers need to climb to the top of the mixer to enter the box. Add to.

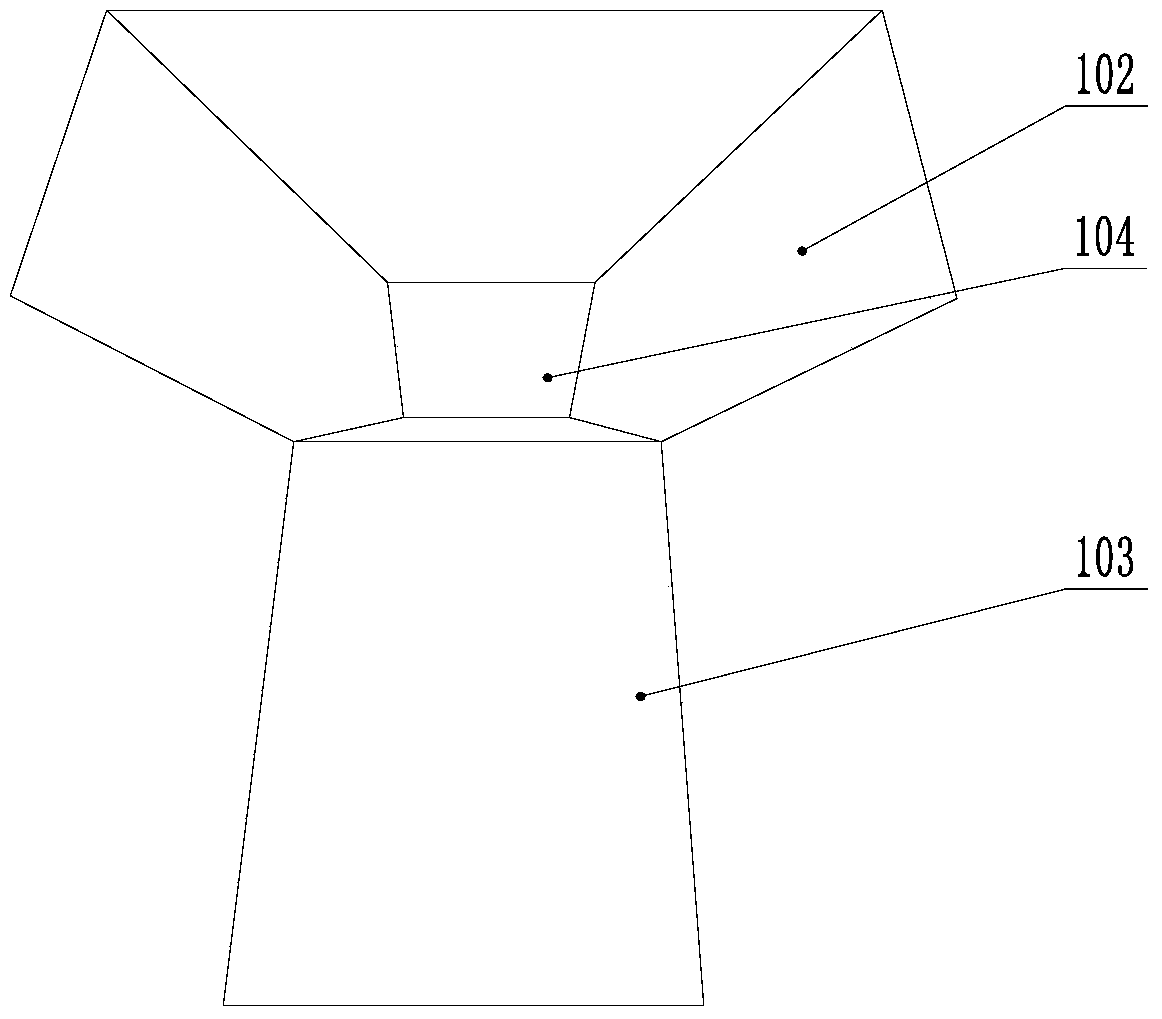

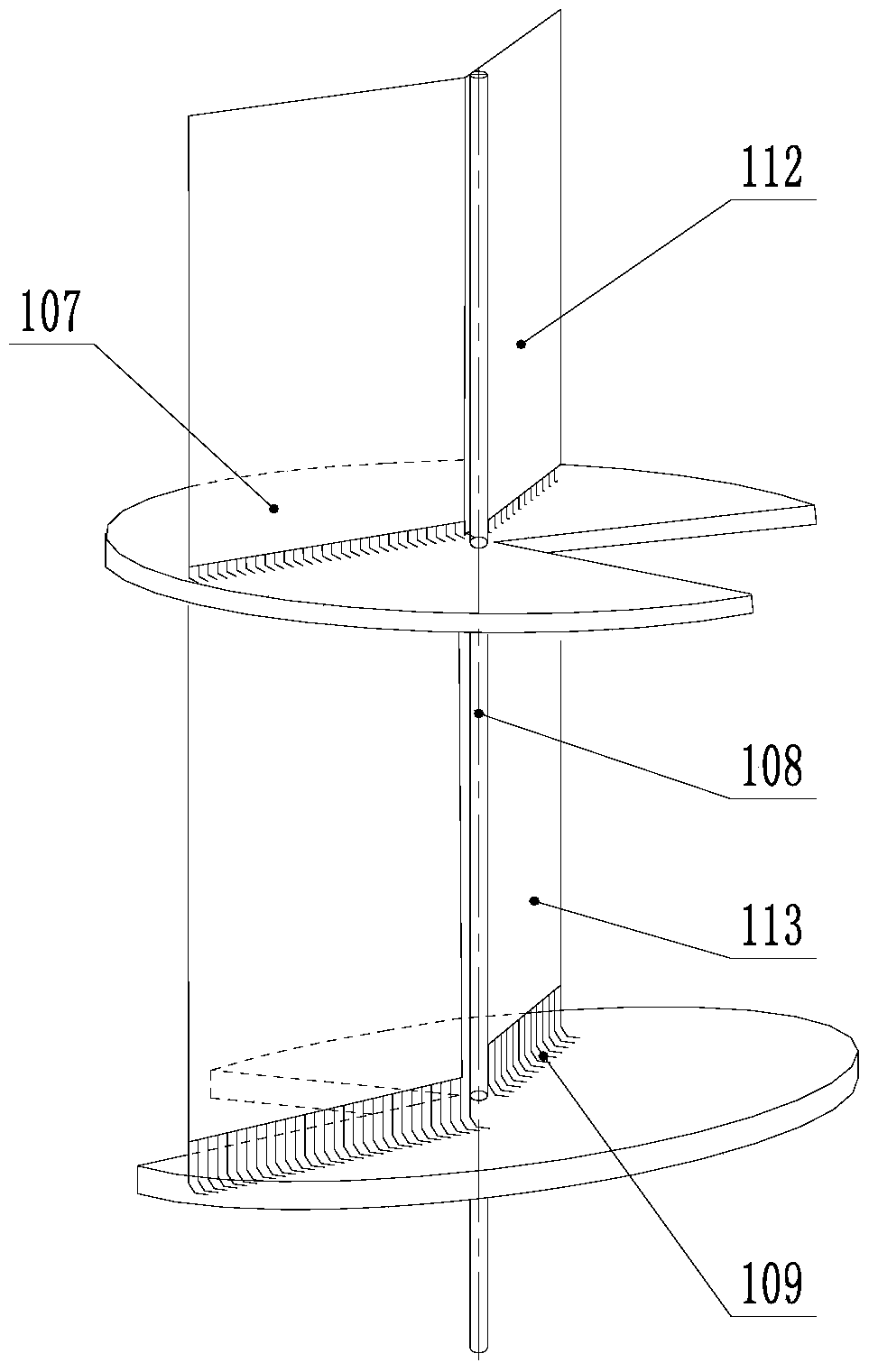

[0040] In view of this, the present invention provides a feed system for a paint mixer with a material control plate. On the basis of ensuring that the automatically transported raw materials can enter the interior of the box to the maximum extent, the feed system can also be arranged at intervals. The material control plate in the material channel can precisely control the speed of adding raw materials.

[0041] In order to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com