Coiling device for composite overlaying of coiled plate

A coiling device and coiling technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to achieve continuity, product performance impact, low work efficiency, etc., to overcome plate width and large-scale products, The effect of saving cost, improving processing performance and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following is a further detailed description of the coiled plate composite surfacing coiling device of the present invention through specific embodiments.

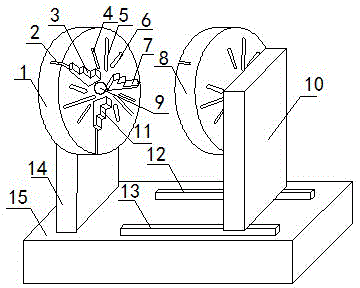

[0008] Such as figure 1 As shown, the coiling plate composite surfacing coiling device of the present invention is characterized in that: the device is provided with two synchronously driven circular claw plates 1 and 8, and the claw plate is provided with a retractable three-claw occlusal positioning block 3, 7, 11, adjust the position according to the inner diameter of the coiling of the workpiece, the left claw plate 1 is connected to the motor drive gearbox 14 for its power through the transmission main shaft 9, and the drive gearbox 14 is fixed on the base 15 of the device. The right claw plate 8 is connected with the motor gearbox 10 for powering it through the transmission spindle. The sliding guide rails 12 and 13 are arranged under the drive gearbox 10 and are installed on the device base as a whole that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com