Suit door grinding machine

A technology of grinding machine and set door, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding workpiece planes, etc. It can solve the problems of laborious grinding, low efficiency, and high cost, and achieve high grinding efficiency. Strong controllability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

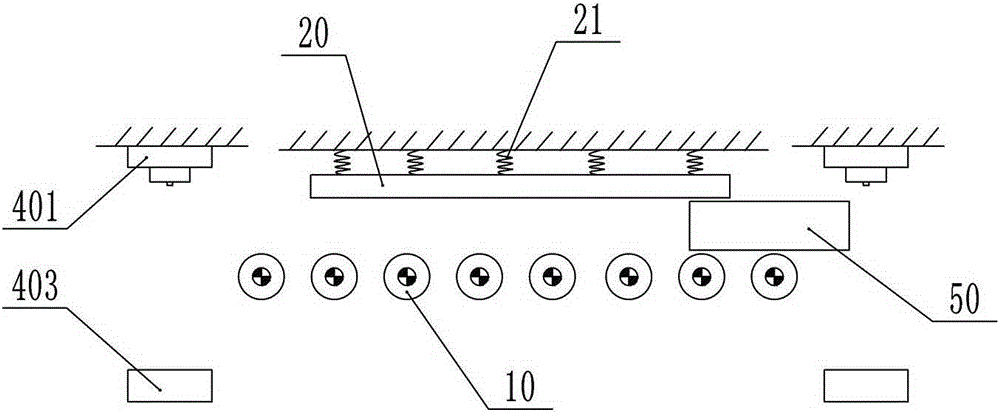

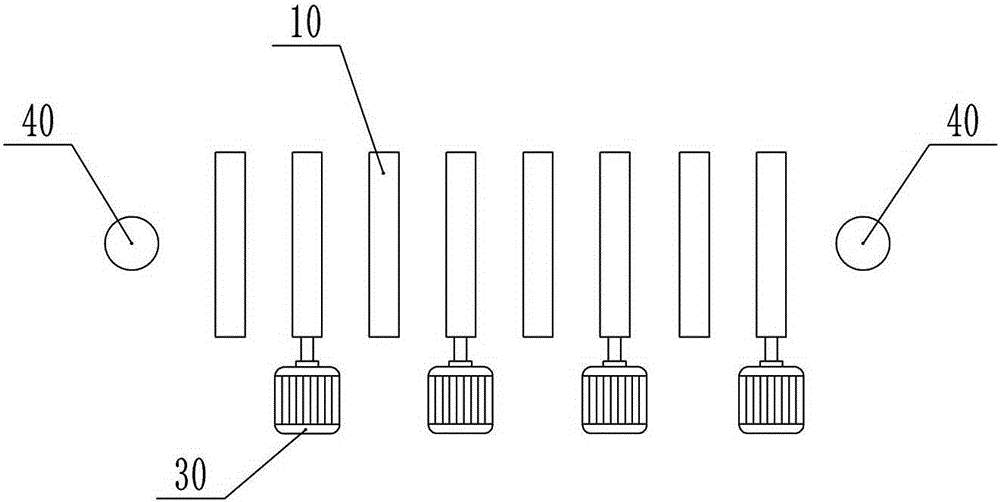

[0015] The reference signs in the accompanying drawings include: grinding roller 10 , grinding plate 20 , elastic member 21 , motor 30 , infrared unit 40 , infrared emitter 401 , infrared receiver 403 , and plank 50 .

[0016] Such as figure 1 , figure 2 As shown, the set door grinding machine includes a frame, a grinding plate 20, an elastic member 21, a reversely rotatable motor 30, an infrared unit 40, a controller and eight grinding rollers 10. The infrared unit 40 includes an infrared transmitter 401 and an infrared receiver 403. There are two infrared units 40, which are respectively located at the material inlet and the material outlet. Elastic piece 21 is stage clip, and the lower end of elastic piece 21 is connected on the grinding plate 20, and the upper end is connected on the frame. The grinding plate 20 is located above the grinding roller 10 , and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com