Intelligent guiding type mechanical arm vision system and work method thereof

A vision system and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of cumbersome processing, low intelligence, inconsistent communication protocols, etc., and achieve simplification of cumbersome processes, high intelligence, and stability The effect of reliable communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

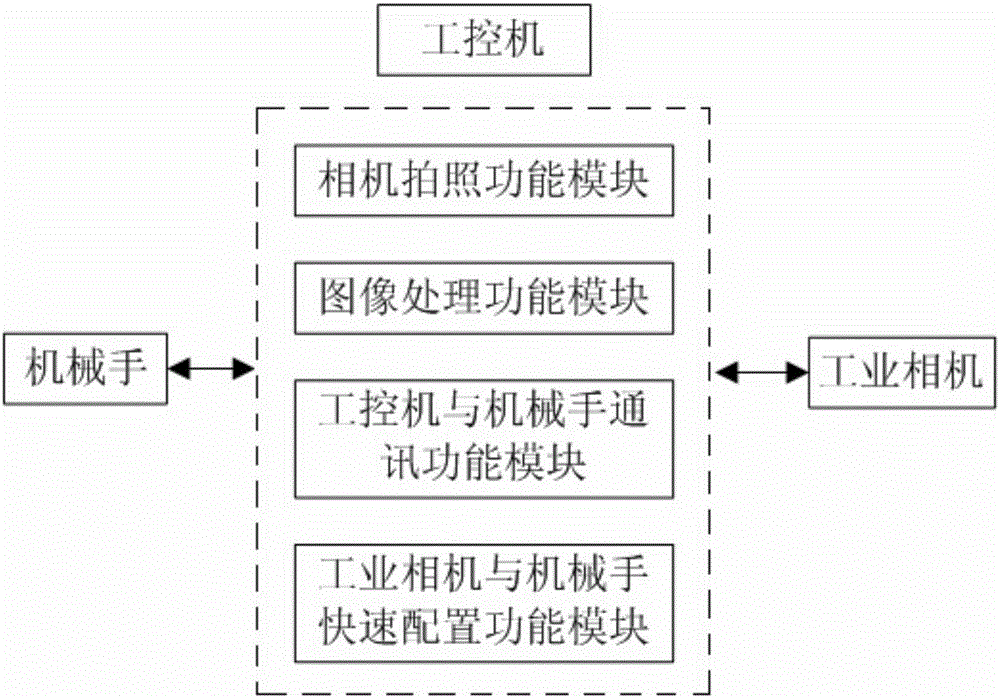

[0035] Such as figure 1 As shown, the intelligent guided manipulator vision system of the present invention includes: manipulator, industrial camera and industrial computer.

[0036] The manipulator is used for grasping and processing the workpiece.

[0037] The industrial camera is used to acquire workpiece images.

[0038] The industrial computer is installed with a camera photographing function module based on the NIVisionBuilder platform development setting, an image processing function module, an industrial computer and a manipulator communication function module, an industrial camera and a manipulator rapid configuration function module, and is used to control the industrial camera to take pictures, The image processing of the acquired workpiece image, the communication between the industrial computer and the manipulator, and the rapid configuration of the industrial camera and the manipulator. Among them, NIVisionbuilder is a machine vision development platform develo...

Embodiment 2

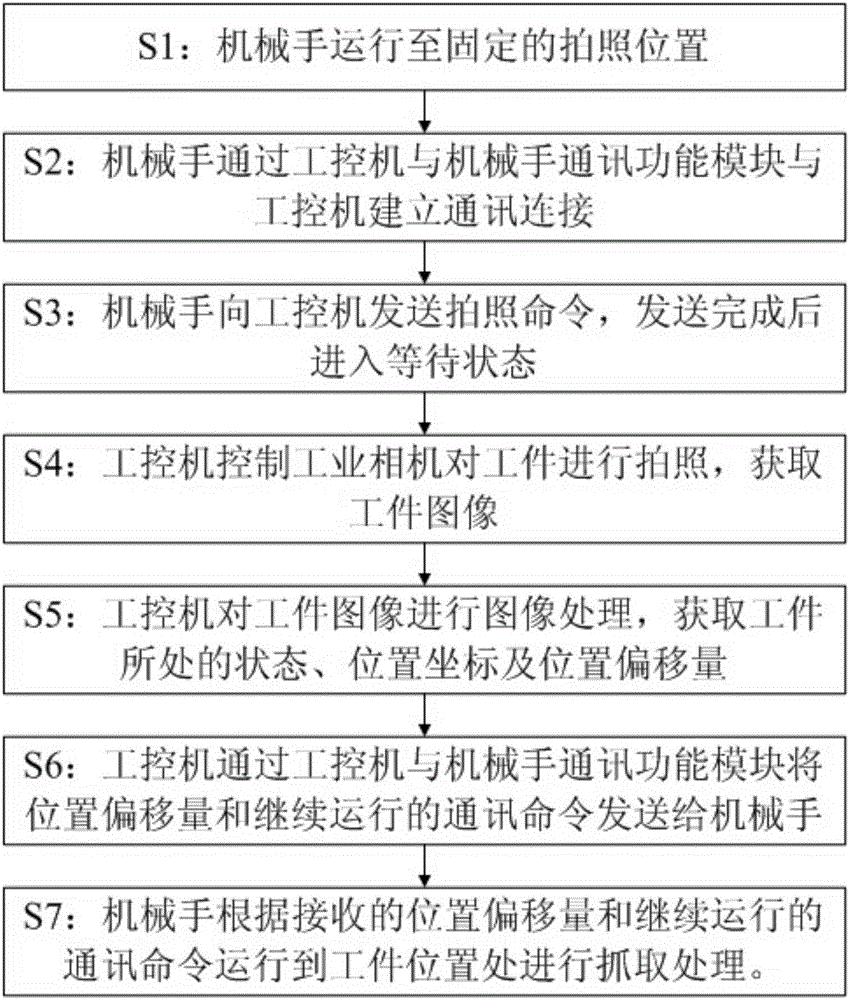

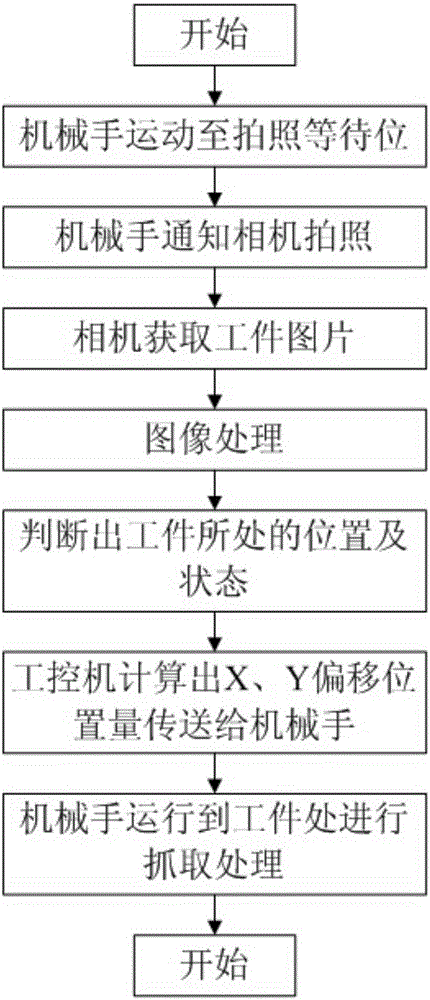

[0052] Such as figure 2 As shown, the working method of the intelligent guided manipulator vision system of the present invention comprises the following steps:

[0053] S1: The manipulator moves to a fixed position for taking photos.

[0054] S2: The manipulator establishes a communication connection with the industrial computer through the industrial computer and the manipulator communication function module.

[0055] S3: The manipulator sends a photographing command to the industrial computer, and the manipulator enters a waiting state after the sending is completed.

[0056] S4: The industrial computer controls the industrial camera to take pictures of the workpiece and acquire images of the workpiece.

[0057] S5: The industrial computer performs image processing on the image of the workpiece through an image processing module, and acquires the state, position coordinates, and position offset relative to the calibration point of the workpiece.

[0058] S6: The industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com