A mold for manufacturing medical mask airbags

A technology for molds and masks, which is applied in the field of molds for manufacturing medical mask airbags. It can solve the problems of increasing trimming trimmings, redundant trimmings, and affecting product quality, so as to improve product quality, reduce multiple processes, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

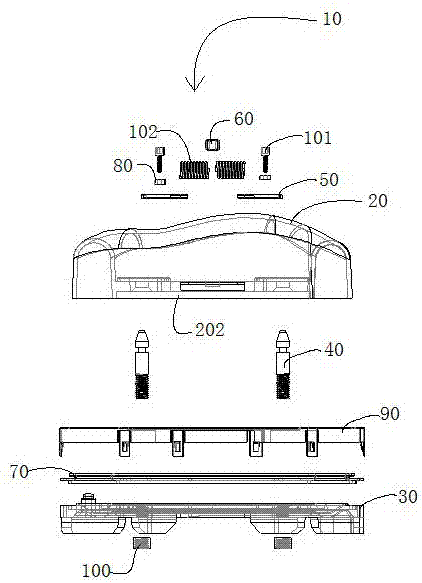

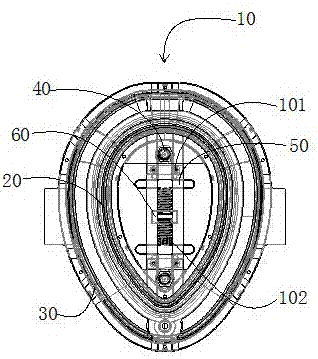

[0041] Such as figure 1 Shown, is the explosion diagram of the overall structure of the present invention, as figure 2 Shown is the assembly drawing of upper mold 20 and lower mold 30 of the present invention, from figure 1 and figure 2 It can be seen that a mold 10 for manufacturing the airbag of a medical mask of the present invention includes:

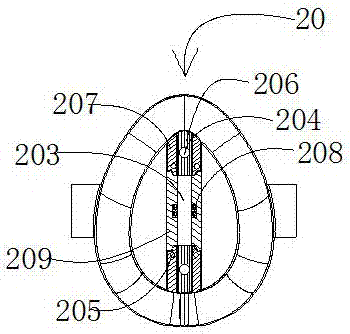

[0042] An upper mold 20 , an upper molding cavity 201 is arranged around the upper mold 20 , the middle part of the upper mold 20 penetrates up and down, and a locking plate 202 is arranged in the middle part of the upper mold 20 .

[0043] A lower mold 30, the lower mold 30 is provided with a lower molding cavity 301 matching with the upper molding cavity 201 of the upper mold 20 around the lower mold 30, and one end of the lower molding cavity 301 is provided with an air nozzle, so The middle part of the lower mold 30 penetrates up and down, and two locking blocks 302 are provided at both ends of the middle part of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com