A sun-facing drying rack that is convenient for taking fabrics

A technology for drying racks and fabrics, applied in the field of drying racks, which can solve the problems of increasing drying time, slow drying speed of cloth, and reduced overall efficiency of drying cloth, and achieves the effect of convenient storage and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

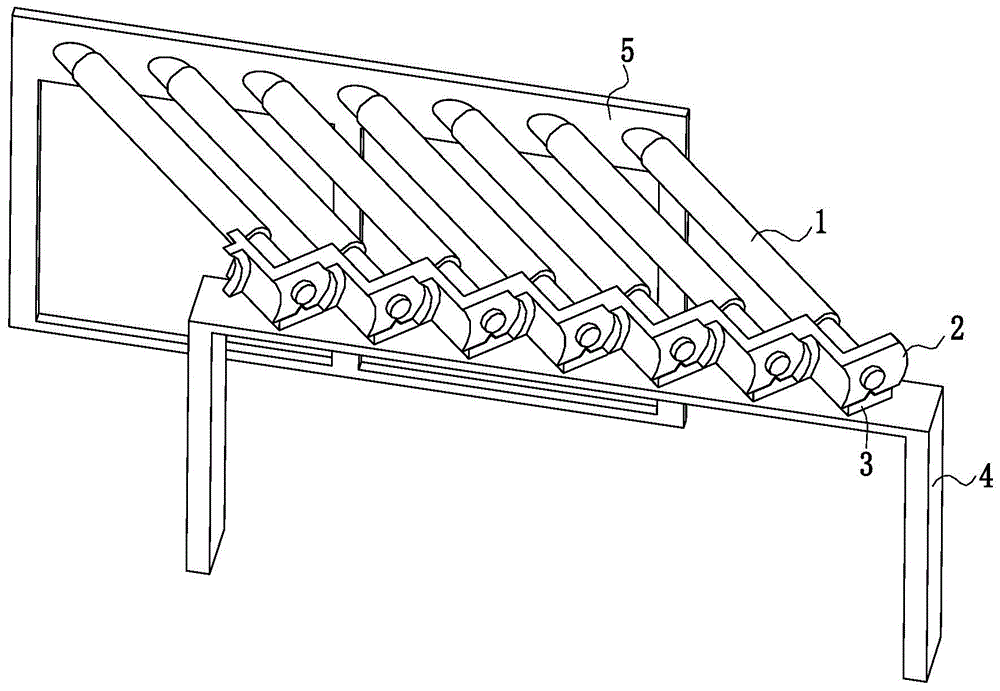

[0017] like figure 1 , a sun-facing drying rack in this embodiment, which is convenient for taking fabrics, includes a drying rod 1, a clamping block 2, a fixing block 3, a front bracket 4 and a rear bracket 5; the front bracket 4 is an inverted "凵" Shape; Described back support 5 is the square frame shape that vertically places.

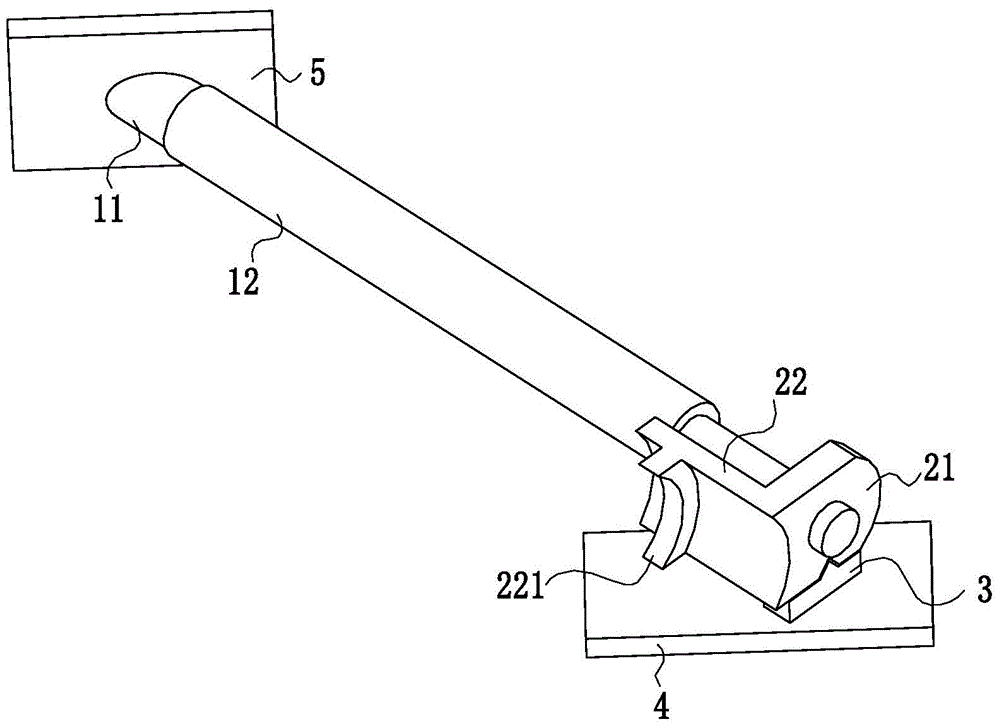

[0018] like figure 2 , the fixed block 3 is flat square, the top surface of the fixed block 3 is provided with an inverted "V" shaped protruding belt, and the bottom of the fixed block 3 is welded on the top of the front bracket 4, the number of fixed blocks 3 is seven, and The seven fixing blocks 3 are linearly arranged side by side on the top of the front bracket 4 successively.

[0019] like figure 1 , figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com