Leak detection method of underground diaphragm wall

A technology of underground continuous wall and detection method, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve the problems of damage to the wall structure, increase the construction cost, affect the construction period, etc., and achieve high detection resolution, Sensitivity to resistivity differences and the effect of a large amount of data collected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

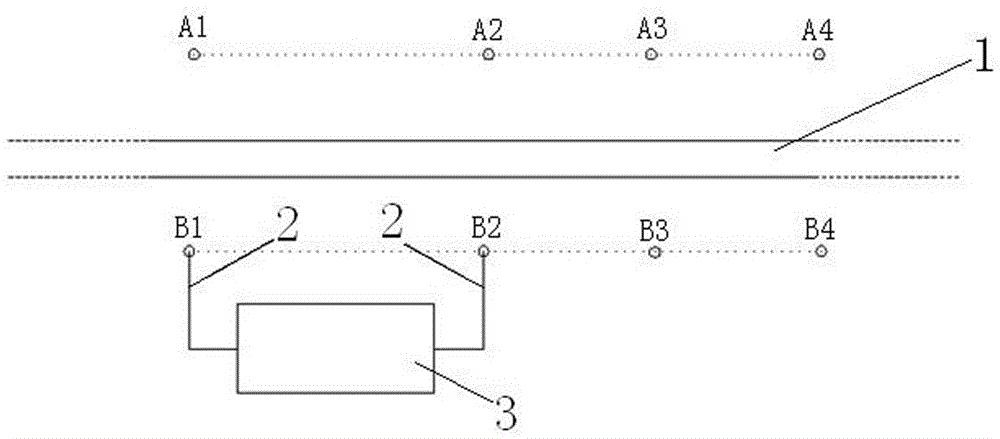

[0017] Embodiment one: if figure 1 As shown, the underground diaphragm wall 1 is set in the foundation pit (the foundation pit is not shown). This embodiment is used to detect whether there is leakage on the wall of the underground diaphragm wall and the location and range of the leakage point.

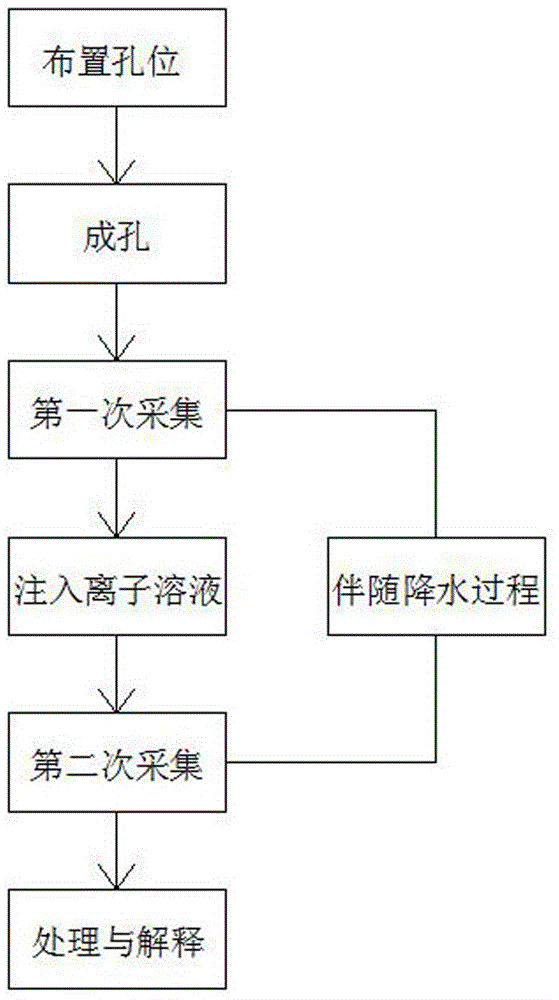

[0018] The leakage detection method of underground diaphragm wall 1 in the present embodiment comprises the following steps:

[0019] 1) Layout hole position: such as figure 1 As shown, test holes A1-A4 and test holes B1-B4 are set up on the inner and outer sides of the foundation pit and within a certain range from both sides of the underground diaphragm wall 1 . The test holes A1-A4 and B1-B4 on the inner and outer sides of the foundation pit should be 1-2m away from the underground diaphragm wall respectively. effective detection. The connection line of the test hole A1-A4 and the connection line of the test hole B1-B4 are kept parallel to the underground diaphragm wall 1, and t...

Embodiment 2

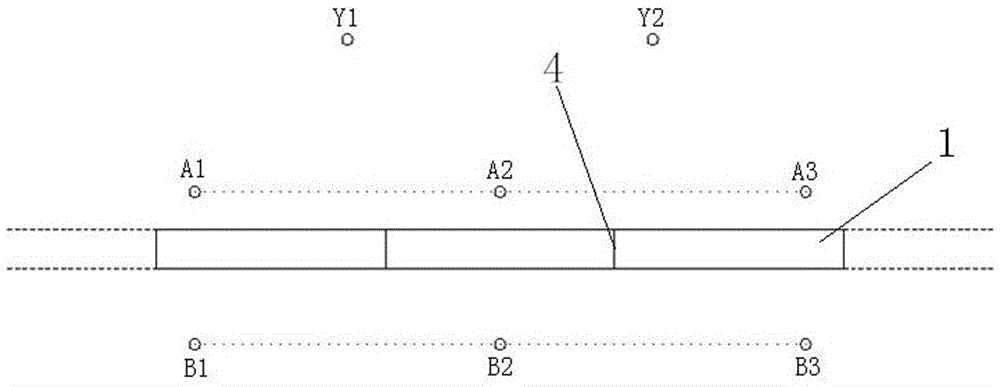

[0024] Embodiment 2: Compared with Embodiment 1, this embodiment differs in that: figure 2 As shown, ion solution injection holes Y1 and Y2 are opened outside the foundation pit, and the ion solution injection holes Y1-Y2 are located outside the test holes A1-A3 outside the underground diaphragm wall 1 . Such as image 3 As shown, after the first detection work is completed, low-resistance ion solutions of appropriate concentrations are injected into the ion solution injection holes Y1 and Y2 respectively. Due to the difference in water pressure, the groundwater outside the foundation pit will flow into the foundation pit. If there is leakage in the underground diaphragm wall 1, the low-resistance ion solution injected into the ion solution injection holes Y1 and Y2 outside the foundation pit will pass through the seepage of the underground diaphragm wall 1. Leaks flow to the inside of the foundation pit. Then in "data processing and judgment", the resistivity profile detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com