Multi-direction fastening assemblies adjustable in direction

A fastening component and fastening technology, which is applied to threaded fasteners, connecting components, screws, etc., can solve the problems of long processing time, high cost, and increased frame structure processing and installation costs, so as to simplify the installation process and increase The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

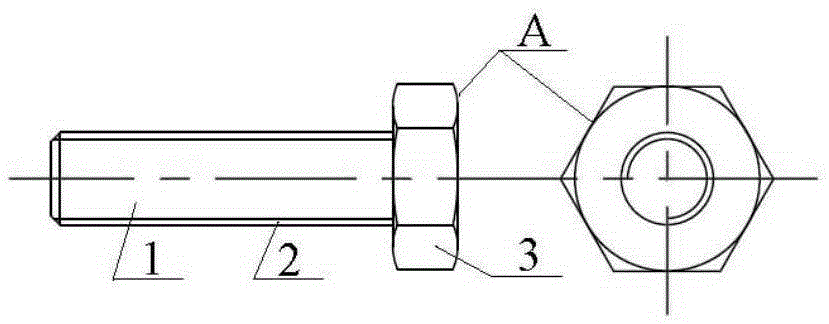

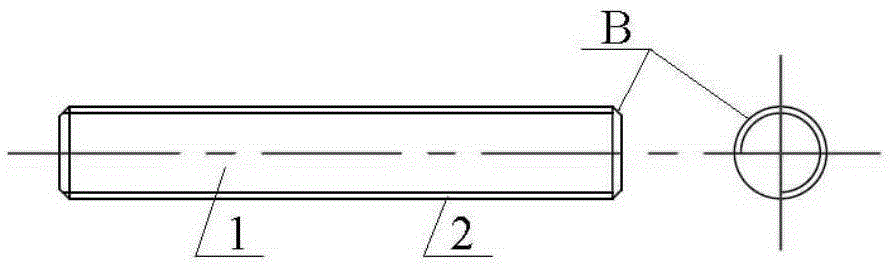

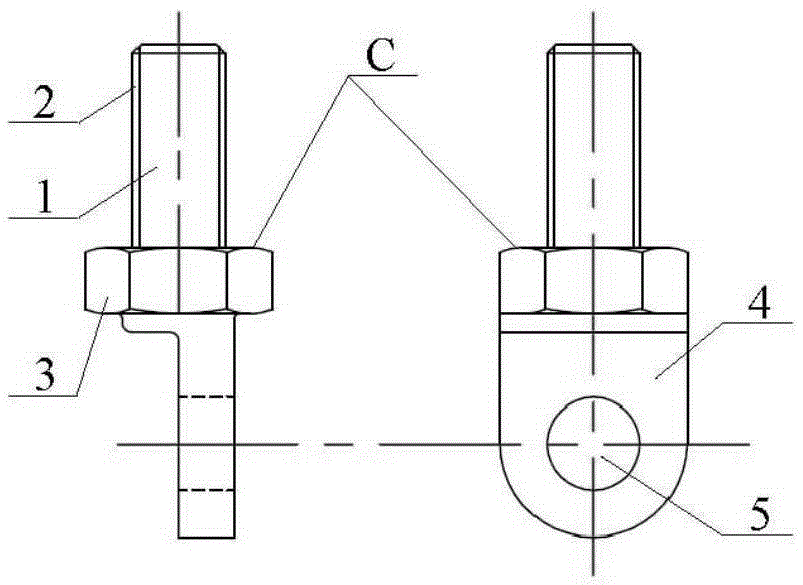

[0028] A set of multi-directional fastening assemblies with adjustable directions according to the present invention has four types in total, including one type of three-way fastening assembly, one type of four-way fastening assembly, one type of five-way fastening assembly, and one type of six-way fastening assembly. One type of component. The multi-directional fastening assembly consists of standard bolts or standard screws, and one or two types of single-rod around-axis bolts and double-rod around-axis bolts. Figure 1A Provided is a schematic diagram of the structure of the standard bolt A of the parts that make up the multi-directional fastening assembly, Figure 1B Provided is a schematic diagram of the structure of the standard screw B of the parts that make up the multi-directional fastening assembly, Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com