Turtle-shell-imitating valve bodies and knock valve

A valve body, tortoise shell technology, applied in the field of ventilation and anti-explosion valves and their valve bodies, can solve the problems of long closing time, limited ability to resist high-strength shock waves, low structural strength, etc. The effect of improving anti-knock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

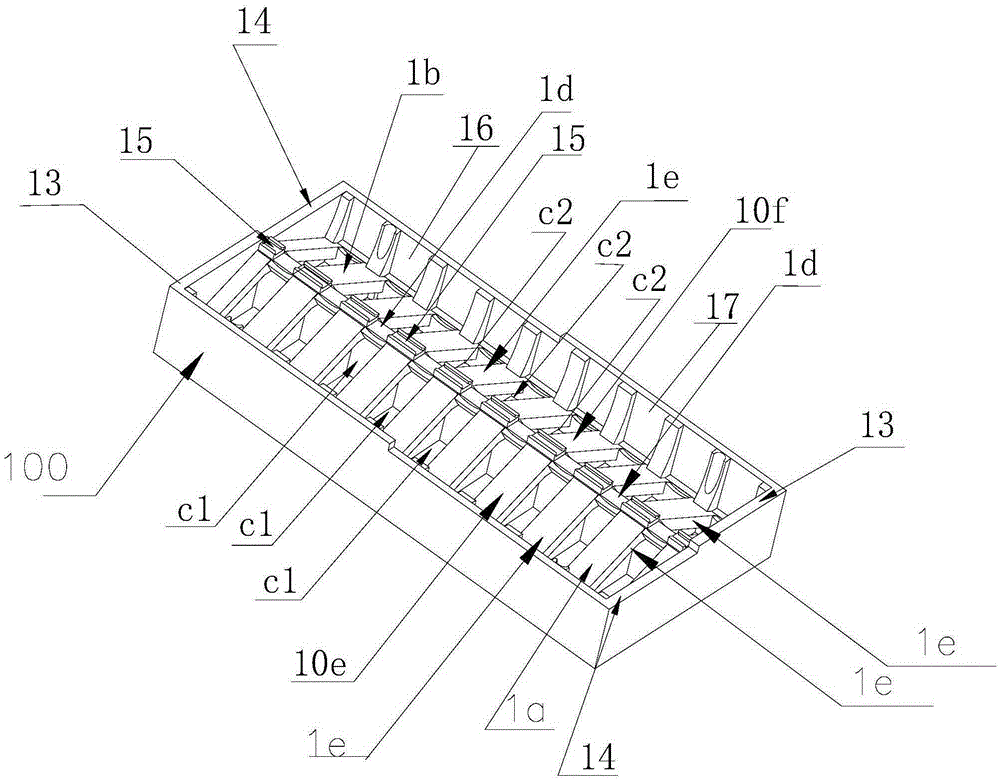

[0072] Example 1: Combining Figure 5 to Figure 8 It can be seen that

[0073] An imitation tortoiseshell valve body is formed by casting a quadrangular frame body 100, a first support body 1a and a second support body 1b. Two intersecting first support bodies 1 a and second support bodies 1 b arranged symmetrically are disposed inside the frame body 100 . The first supporting body 1a is provided with through grooves c1 at intervals along the direction of the spine 1d. The second supporting body 1b is provided with through grooves c2 at intervals along the direction of the spine 1d. The through groove c1 on the first support body 1a and the through groove c2 on the second support body 1b are arranged symmetrically. The intersection of the first support body 1a and the second support body 1b is the spine 1d, and the first support body 1a and the second support body 1b on both sides of the spine 1d form a skeleton 1e.

[0074] The spine 1d extends toward the inner sides 12 o...

Embodiment 2

[0077] Example 2: Combining Figure 9 to Figure 17 It can be seen that

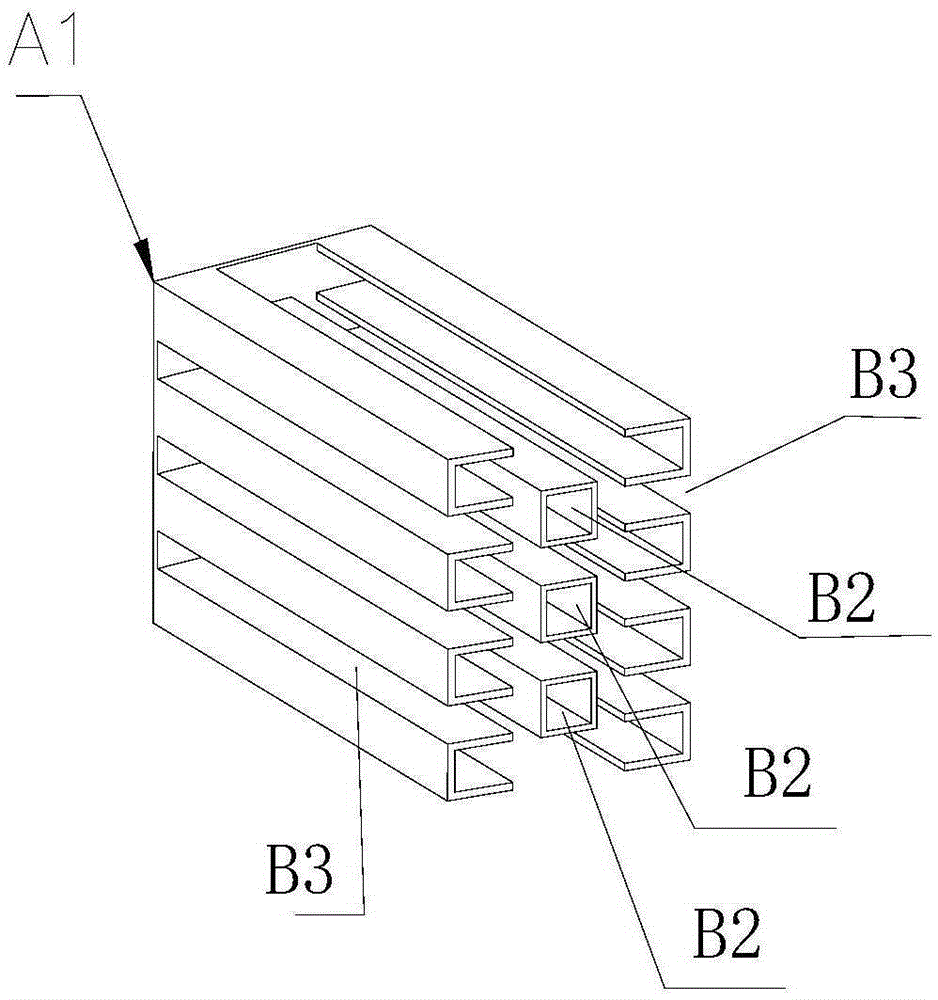

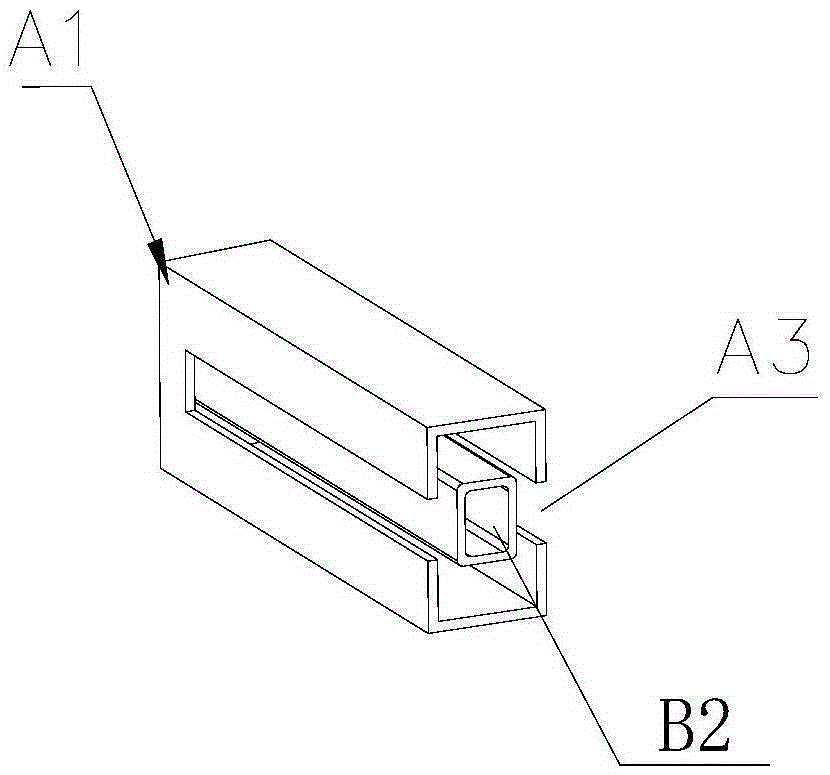

[0078] An antiknock valve with a small spool imitating a tortoiseshell array, comprising several spools 200, a first valve body A3 and a second valve body A4.

[0079] The first valve body A3 includes a frame body 101, and two intersecting third support bodies 2a and fourth support bodies 2b are symmetrically arranged in the quadrangular frame body 101, and the frame body 101 and the third support body 2a and the fourth support body 2b are One. The intersection of the third support body 2a and the fourth support body 2b is the spine 2d, and the parts of the third support body 2a and the fourth support body 2b on both sides of the spine 2d are the skeleton 2e. The third supporting body 2a is provided with through grooves 2c1 at intervals along the direction of the spine 2d. The fourth supporting body 2b is provided with through grooves 2c2 at intervals along the direction of the spine 2d. The through g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com