Connector structure for double-stage synchronous vibration

A technology of synchronous vibration and connectors, which is applied in vibration testing, testing of machines/structural components, measuring devices, etc. It can solve the problems of reducing test fidelity, damage to the shaking table body, and inability to stand upright, so as to achieve high efficiency in the testing process Fast, eliminates lateral pulling force, and has the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

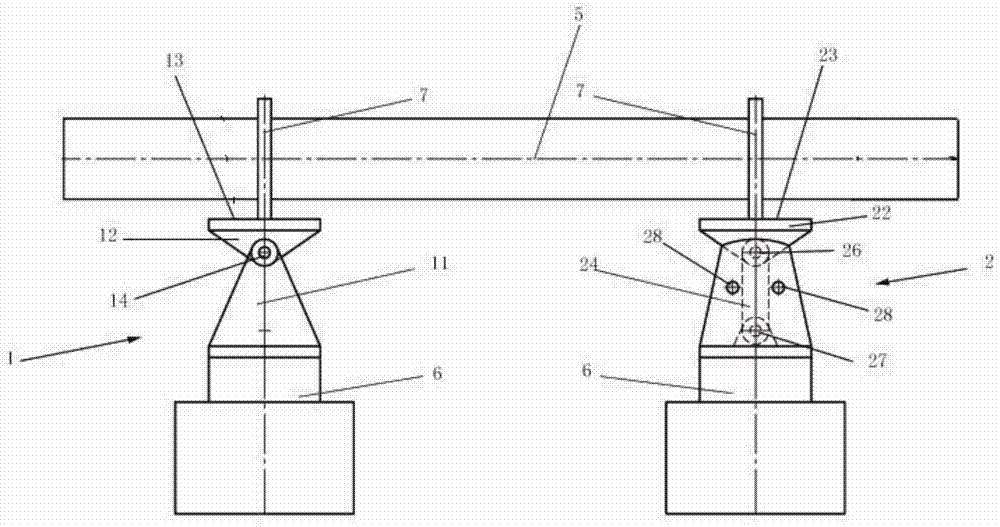

[0035] See attached image 3 As shown, a joint structure for double-stage synchronous vibration includes a single-hinge joint 1 and a double-hinge joint 2, wherein:

[0036] The single hinge connector 1 includes a first base 11 and a first work surface 12 , the first work surface 12 has a first bearing plane 13 , and the first work surface 12 is connected to the first base 11 through a first hinge 14 .

[0037] The double hinge connector 2 includes a second base 21, a connecting rod 24 and a second work surface 22, the second work surface 22 has a second bearing plane 23, and the second work surface 22 is connected to the second base through the connecting rod 24 21, the second base 21 has two side walls 25 facing each other at intervals, the connecting rod 24 is arranged between the two side walls 25, and the upper end of the connecting rod 24 is connected to the second work surface 22 through the second hinge 26 , the lower end of the connecting rod 24 is connected to the b...

Embodiment 2

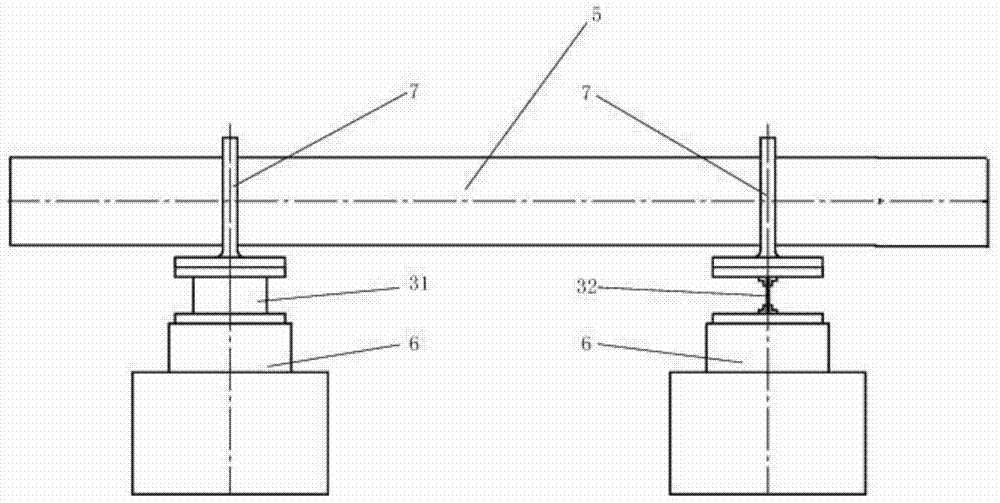

[0042] See attached Figure 4 As shown, the difference between this embodiment and Embodiment 1 is: a joint structure for double-stage synchronous vibration, including a pair of double-hinge joints 2;

[0043] The double hinge joint 2 includes a second base 21, a connecting rod 24 and a second work surface 22, the second work surface 22 has a second bearing plane 23, and the second work surface 22 connects the second work surface 22 through the connecting rod 24 and the second work surface 22. The bottom of the base 21 is connected, and the second base 21 has two side walls 25 facing each other at intervals. connected, the lower end of the connecting rod 24 is connected to the bottom of the second base 21 through the third hinge 27, and the second hinge 26 is arranged parallel to the axis of the third hinge 27; A limiting structure is provided on the side to limit the swing angle of the connecting rod 24 .

[0044] In the state of use, the second hinges 26 of the two double-hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com