Bending-torsion compound dynamic loading device

A dynamic loading, bending and torsion technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as jumping, rigid lever loading system cannot realize bending and torsion compound dynamic loading, and unstable transmission, achieving low energy consumption and unique structure , Easy operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

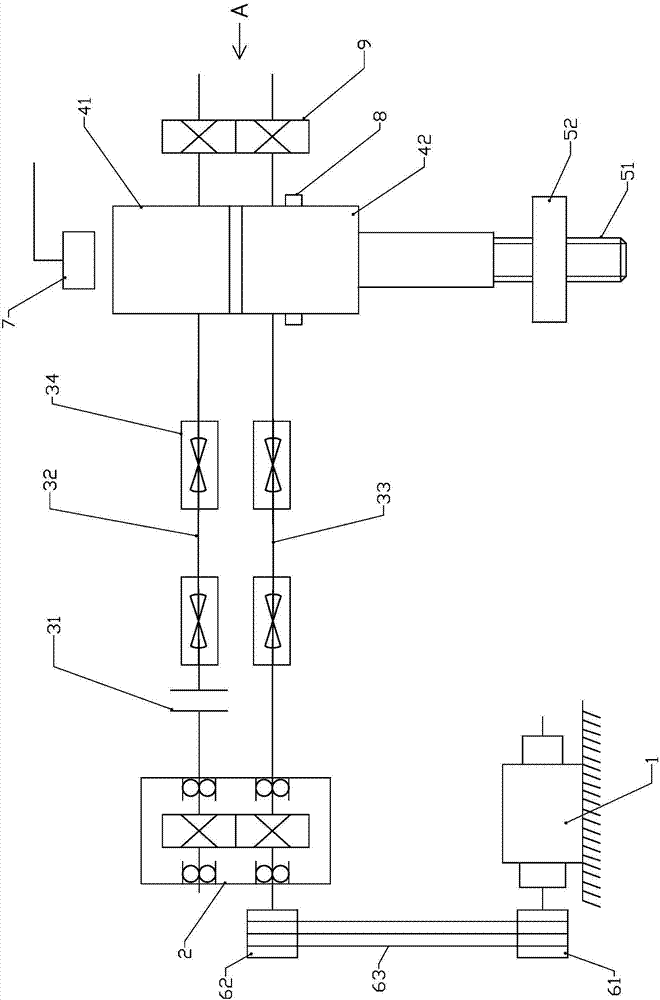

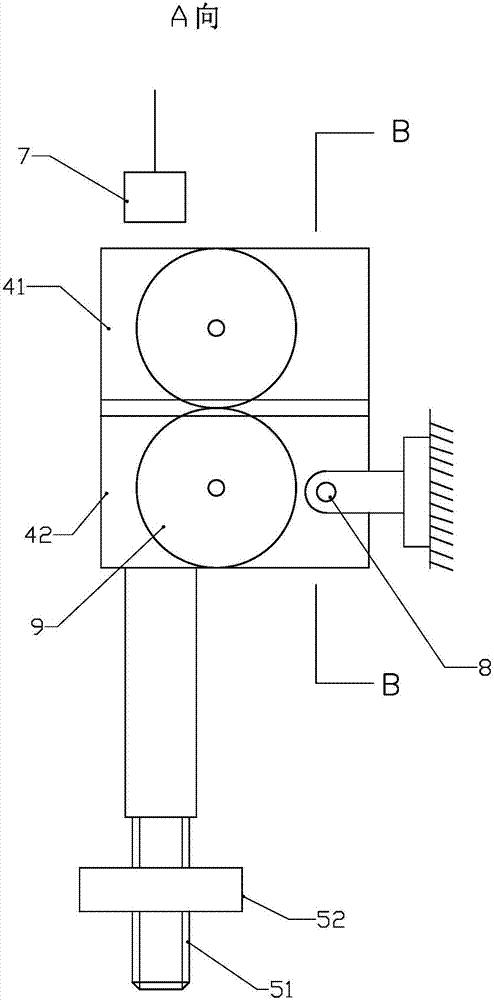

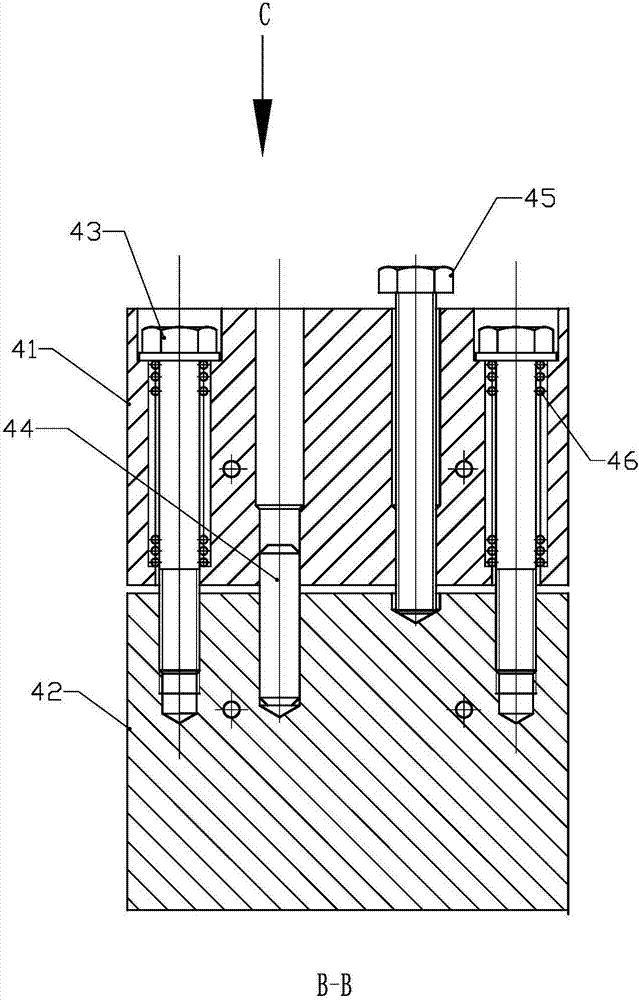

[0018] Refer to the attached figure 1 to attach Figure 4 The bending-torsion compound dynamic loading device of the present invention will be described in detail below.

[0019] The bending-twisting compound dynamic loading device of the present invention has a structure comprising a motor 1, a gear box 2, a transmission shaft staggered angle adjustment system, a pivot box assembly adjustment system and a lever loading system, and the motor 1 is connected to the gear box 2 through a transmission system. The other end of the gearbox 2 is connected with the pivot box assembly and adjustment system through the transmission shaft staggered angle adjustment system, the lever loading system is connected with the pivot box assembly adjustment system, and the pivot box assembly adjustment system is also connected with the displacement The sensor 7 is connected;

[0020] Described transmission system comprises motor pulley 61, gearbox pulley 62 and belt 63, and described motor pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com