Shale gas desorption canister capable of regulation and control of desorption temperature and pressure

A shale gas, desorption technology, applied in the direction of analysis of materials, instruments, etc., to achieve scientific structure, timely and accurate measurement data, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

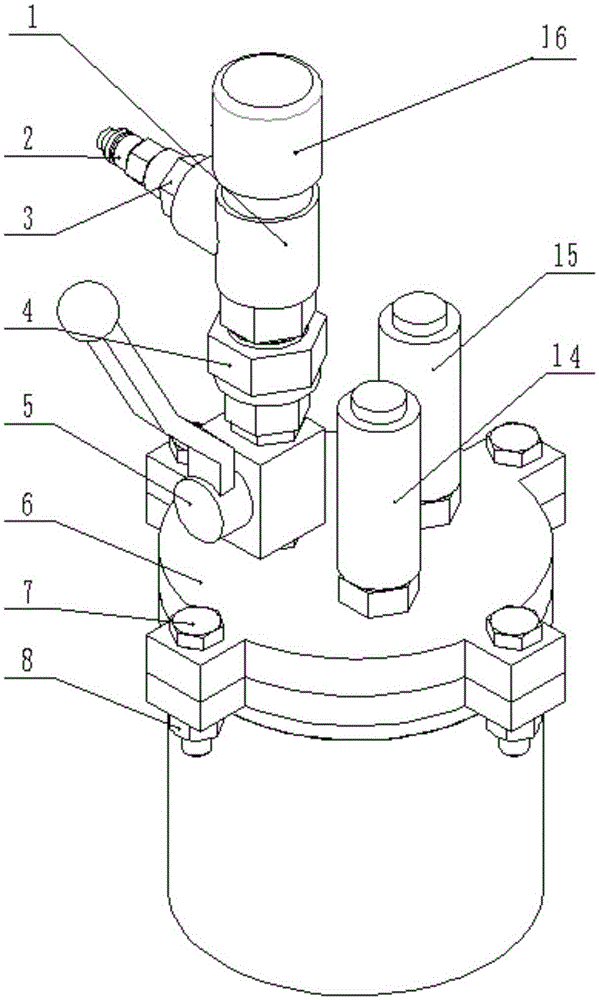

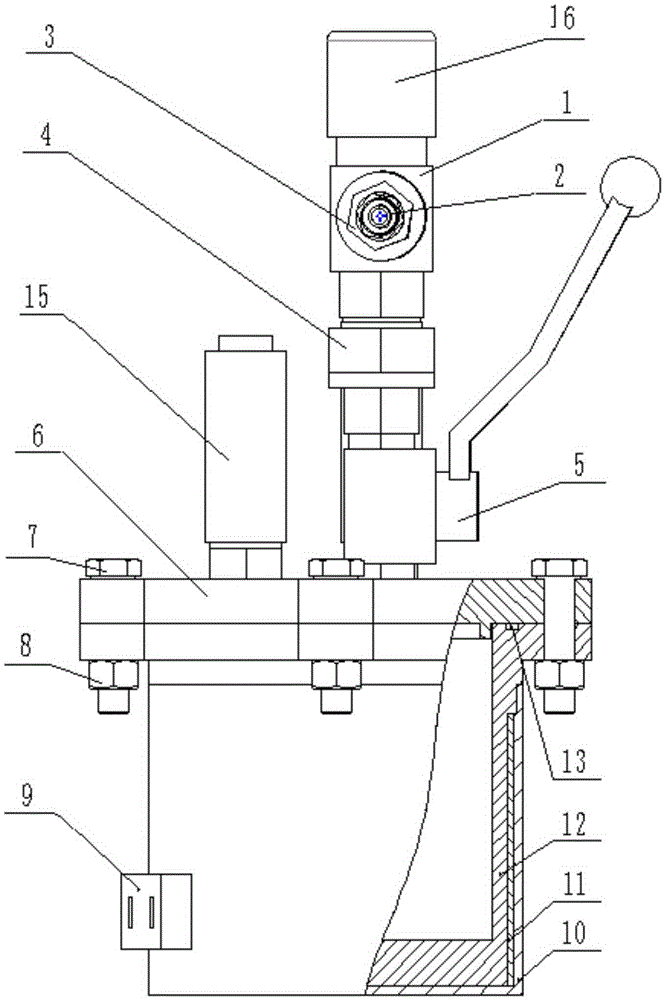

[0018] Embodiment 1: The present invention provides a shale gas desorption tank with adjustable desorption temperature and pressure. Its overall appearance and structure are as follows: figure 1 , 2 As shown, there are pressure regulating valve 1, quick plug joint 2, connection sleeve A3, connection sleeve B4, ball valve 5, desorption tank cover 6, bolts 7, nuts 8, wiring socket 9, desorption tank outer cylinder 10, crawler type Heating layer 11, inner cylinder 12, O-ring 13, pressure sensor 14, temperature sensor 15; the pressure regulating valve is installed on the desorption tank cover 6 through the connecting sleeve B4 and ball valve 5; the upper end of the pressure regulating valve 1 is provided with The valve nut 16, the air outlet end of the side of the pressure regulating valve 1 is connected with the quick plug joint 2 through the connecting sleeve A3; the lower end of the pressure regulating valve is connected to the ball valve 5 through the connecting sleeve B4; the...

Embodiment 2

[0020] Example 2: The shale gas desorption tank provided in Example 1, which can control the desorption temperature and pressure, was used to carry out field field shale gas desorption experiments.

[0021] The specific operation process is: clean the shale core just extracted and put it into the desorption tank; fill the desorption tank with saturated saline (if high temperature heating is required, put in heating oil); cover the desorption tank cover 6 , and tighten the four groups of bolts 7 and nuts 8 to tightly connect the desorption tank cover 6 with the desorption tank inner cylinder 12; adjust the valve nut 16 on the upper end of the pressure regulating valve 1, and turn clockwise to increase the pressure in the desorption tank, reverse Turn clockwise to reduce the pressure until it reaches the required pressure; connect the wiring socket 9 with an external power supply and a temperature controller to adjust the internal temperature of the desorption tank; connect the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com